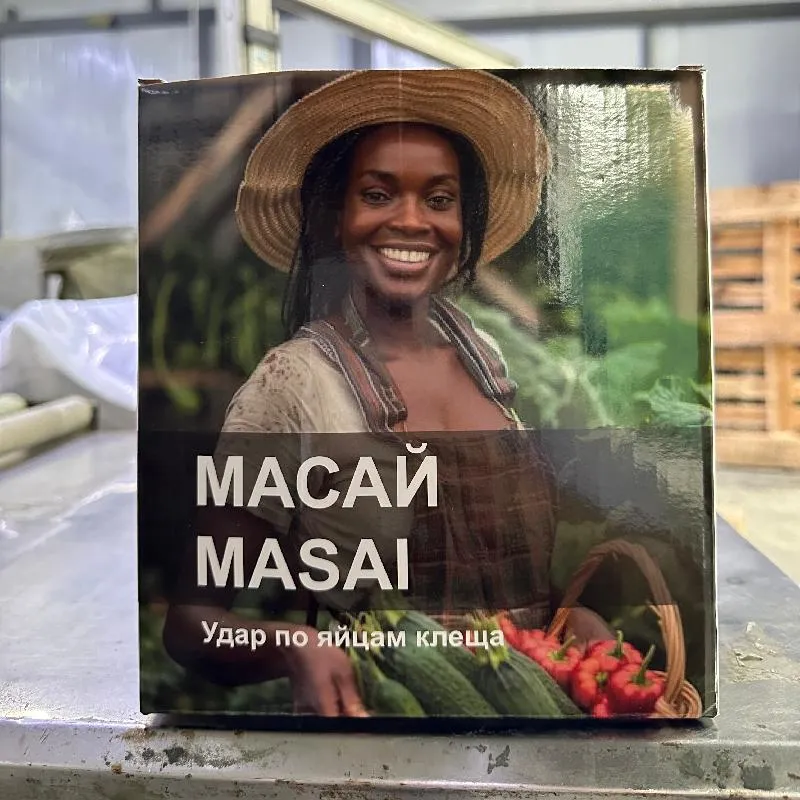

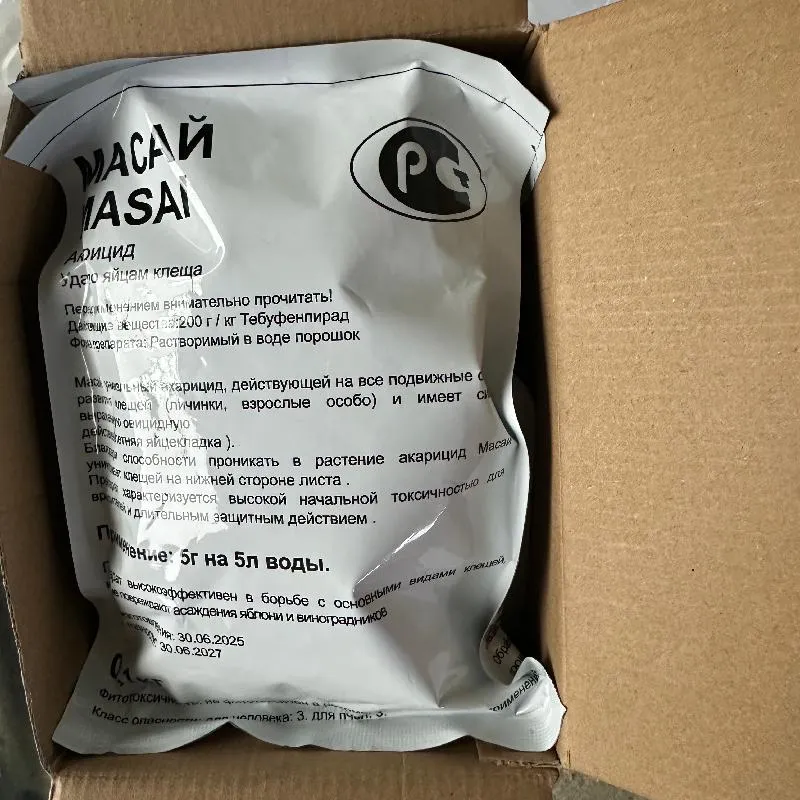

Tebufenpyrad 20% WP,200g/kg SP Insecticide

METI Acaricide (IRAC 21A) for Persistent Mite Pressure

Fast knockdown, long-lasting control, and translaminar reach—Tebufenpyrad 20% WP (200 g/kg) provides contact and ingestion activity against spider, rust, and tarsonemid mites across citrus, pome fruit, berries, grapevine, vegetables, and soybeans, with efficacy on eggs, larvae, nymphs, and adults to reduce flare-ups. Supplied with COA/MSDS and private-label options.

IRAC 21A METI mode (Complex I) for rapid knockdown and durable residual; translaminar movement helps reach mites on leaf undersides; compatible with a range of tank partners (follow local label).

Assay/Formulation: 20% WP (w/w)

Action: contact + ingestion

Coverage: spider / rust / tarsonemid mites

Docs: COA/MSDS

Branding: OEM/private label.

- Designed for Professional Buyers & Bulk Orders

- We support custom packaging, labeling, and formulation to meet your market needs.

- Export wholesale inquiries only.

- Please include destination country, business type (importer/distributor/registrant), and expected volume.

- Retail requests will not be processed.

About Tebufenpyrad 20% WP,200g/kg SP Insecticide

| Product | Tebufenpyrad 20% WP (200 g/kg, w/w) |

| Active (ISO) | Tebufenpyrad |

| IRAC / MoA | 21A — METI (mitochondrial Complex I inhibitor) |

| Formulation | Wettable Powder (WP) |

| Activity | Contact + ingestion; fast knockdown with long-lasting control |

| Movement | Translaminar (reaches mites on the leaf underside) |

| Target mites | Spider mites, rust/eriophyid mites, tarsonemid/broad mites |

| Crops (examples) | Citrus, pome fruit, berries, grapevine, vegetables, soybeans (per label) |

| Packs | 100 g · 250 g · 500 g · 1 kg (custom sizes on request) |

| Documents | COA & MSDS per batch, spec sheet, GHS artwork |

| Branding | POMAIS or OEM/private label (multilingual) |

| Shelf life | 2 years (sealed, cool, dry, ventilated) |

| Safety | Professional use; toxic to aquatic organisms & bees; observe REI/PHI per local label |

| Traceability | Lot & expiry on pack and documents; units aligned (w/w) |

Tebufenpyrad 20% WP

Tebufenpyrad 20% WP is a METI acaricide (IRAC 21A) designed for tough, recurrent mite pressure. It works by inhibiting mitochondrial Complex I, cutting ATP production so mites stop moving and feeding fast, then die—whether they ingest treated tissue or are hit by contact. Unlike knockdown-only options, it combines speed + persistence and shows activity across eggs, larvae, nymphs, and adults, helping suppress rebounds between sprays. The formulation’s translaminar reach penetrates leaf tissue to target mites sheltering on the underside, improving hit-rate where coverage is hardest.

Where it excels: on high-value crops (citrus, pome fruit, berries, grapevine, vegetables, soybeans) facing spider mites, rust/eriophyid mites, and tarsonemid mites. In-season, users see value through longer spray intervals, cleaner foliage, and lower labor per hectare when programs are built correctly and labels are followed.

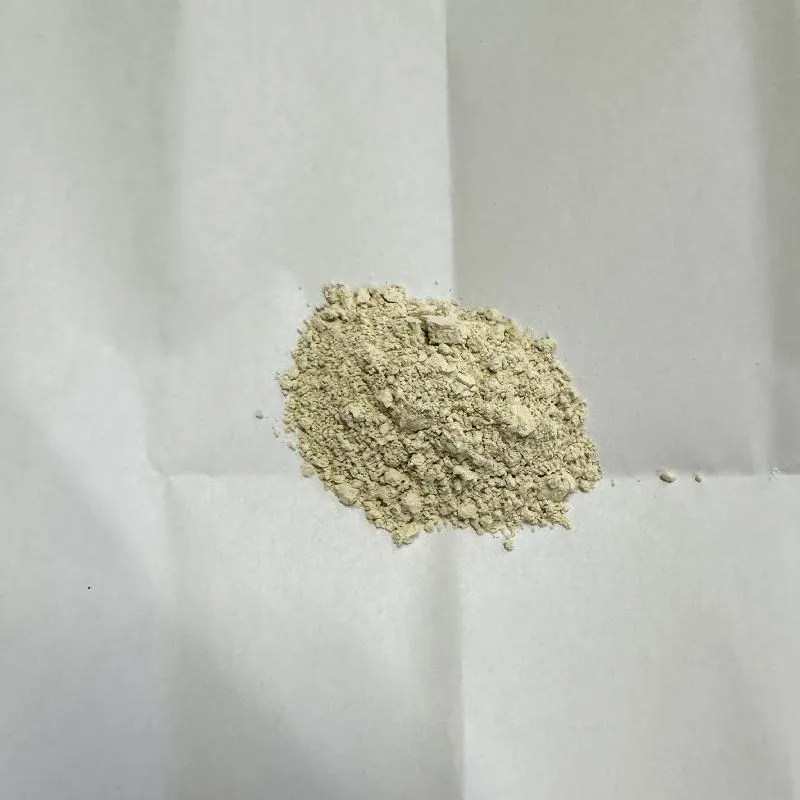

Why WP, and why 20%: the 20% wettable powder balances potency with mixing stability—fast wetting, high suspensibility, and even dispersion in diverse water qualities. That translates into uniform deposition on leaves and predictable performance through calibrated sprayers. Each batch is backed by COA/MSDS and lot/expiry traceability, aligning label, spec, and documents for audits and registrations.

Program fit: built for IPM and resistance stewardship—use as part of a rotation away from 21A groups, time applications to thresholds, and maintain coverage with good nozzle choice and drift management. The product is tank-mix friendly in most programs (jar test first, follow label), making it easy to slot into existing retailer and grower protocols.

Assay & Formulations

Primary offer — Tebufenpyrad 20% WP (200 g/kg, w/w)

A wettable powder engineered for dependable mixing and field performance: fast wetting, high suspensibility, and even dispersion for uniform leaf deposition. Designed for contact + ingestion activity with translaminar reach when used as directed.

Why 20% WP works

- Balanced potency & stability: a 20% load maintains active intensity while protecting formulation integrity.

- Tank performance: quick wetting, strong suspensibility, and smooth re-dispersion after agitation pauses.

- Water tolerance: performs reliably across typical spray-water conditions.

- Coverage confidence: consistent particle size supports even foliar coverage through calibrated sprayers.

Additional supply options

- 95% TC (technical grade) for downstream manufacturing.

- Alternate formulations (e.g., EC/WP lines) available where registered and commercially viable.

- Private label support with multilingual GHS artwork and spec alignment.

Packs & labeling

- WP packs: 100 g · 250 g · 500 g · 1 kg (other sizes on request).

- Documentation: COA/MSDS per batch, lot & expiry on pack and paperwork, units aligned as w/w across label and spec.

- Traceability: product name, assay, formulation, and artwork versions controlled for audits and registrations.

Target Mites & Crops

Built for high-value crops under persistent mite pressure. Tebufenpyrad 20% WP targets key mite groups with contact + ingestion activity and translaminar reach to the leaf underside.

Coverage at a glance (per label & local regulations):

| Crop group | Typical mite targets | Practical notes |

|---|---|---|

| Citrus | Spider mites (Tetranychus spp.), citrus red mite (Panonychus citri), rust mites (Eriophyidae) | Translaminar action helps reach mites on the leaf underside and fruit surface; monitor oily rind scarring from rust mites. |

| Pome fruit (apple/pear) | European red mite (Panonychus ulmi), two-spotted spider mite (T. urticae) | Aim for even canopy coverage; rotate away from IRAC 21A within the season. |

| Berries (strawberry, blueberry, cane fruit) | Two-spotted spider mite, broad mite (Tarsonemidae) | Scout new growth and runners; treat hot spots early to limit spread. |

| Grapevine | Spider mites (Tetranychus spp.), eriophyid/rust mites | Focus on the underside of sun-exposed leaves; maintain spray volume for inner canopy. |

| Vegetables (solanaceous, cucurbits, leafy) | Two-spotted spider mite; broad/russet/eriophyid mites by crop | Use fine-to-medium droplets for coverage; avoid spraying during extreme heat stress. |

| Soybeans | Spider mites (Tetranychus spp.) | Treat at threshold; ensure full leaf coverage on lower canopy. |

Positioning tips

- Start when scouting thresholds are met; treat hot spots rather than the whole block where appropriate.

- Prioritize leaf-underside coverage; calibrate sprayers and maintain agitation after adding WP.

- Build into an IPM rotation—alternate with non-21A modes to protect performance.

- Observe label-specific intervals and PHI; timings vary by crop and market.

Mode of Action & Stewardship

How it works (clear and simple)

Tebufenpyrad is a METI acaricide (IRAC 21A). It inhibits mitochondrial Complex I, cutting off ATP (energy) inside mite cells. With no energy, mites stop moving and feeding quickly and die. It works by contact and ingestion, and its translaminar movement helps reach mites hiding on the leaf underside.

Why this matters in the field

- Fast knockdown ends feeding damage quickly.

- Longer-lasting control helps stretch spray intervals when programs are well designed.

- All life stages: activity from eggs → larvae → nymphs → adults reduces rebound risk between applications.

- Better hit-rate where mites shelter: translaminar reach improves control on the leaf’s underside.

Stewardship: protect performance, slow resistance

- Rotate modes of action: alternate away from IRAC 21A to non-21A groups within the same season.

- Follow label rates and intervals: avoid “low-and-often”; use full labeled rates at the correct timing.

- Limit total 21A uses/season: avoid back-to-back 21A sprays; leave gaps of non-21A treatments between uses.

- Treat at thresholds: scout hot spots early; target pressure before populations explode.

- Integrate IPM: sanitation, resistant varieties, beneficials, and canopy management all reduce selection pressure.

- Tank-mix wisely: only where permitted; jar-test first; ensure physical compatibility and coverage.

- Keep records: field history, product/MoA used, timing, and outcome to guide future rotations.

Application best practice (coverage = control)

- Aim droplets to the leaf underside; use calibrated sprayers and maintain agitation after adding WP.

- Maintain water volume for full canopy coverage; avoid windy conditions and extreme heat stress.

- Respect REI/PHI and local regulations; never exceed label frequency.

Features & Benefits

Fast knockdown, visible stop-feeding

Contact and ingestion activity shuts mites down quickly, curbing feeding damage in the first spray window.

Long-lasting control between sprays

Designed for durable field performance so programs can maintain cleaner foliage and extend intervals when labels are followed.

All life-stage activity (eggs → adults)

Activity across eggs, larvae, nymphs, and adults helps suppress rebounds and stabilize blocks under pressure.

Translaminar reach to the leaf underside

Penetrates leaf tissue to improve hit-rate on mites sheltering below the canopy surface.

Consistent tank performance

20% WP provides fast wetting, strong suspensibility, and even dispersion for uniform deposition and predictable results.

IPM & rotation friendly

Fits resistance-management plans—rotate away from IRAC 21A, treat at thresholds, and integrate cultural/biological tools.

Flexible supply & private label

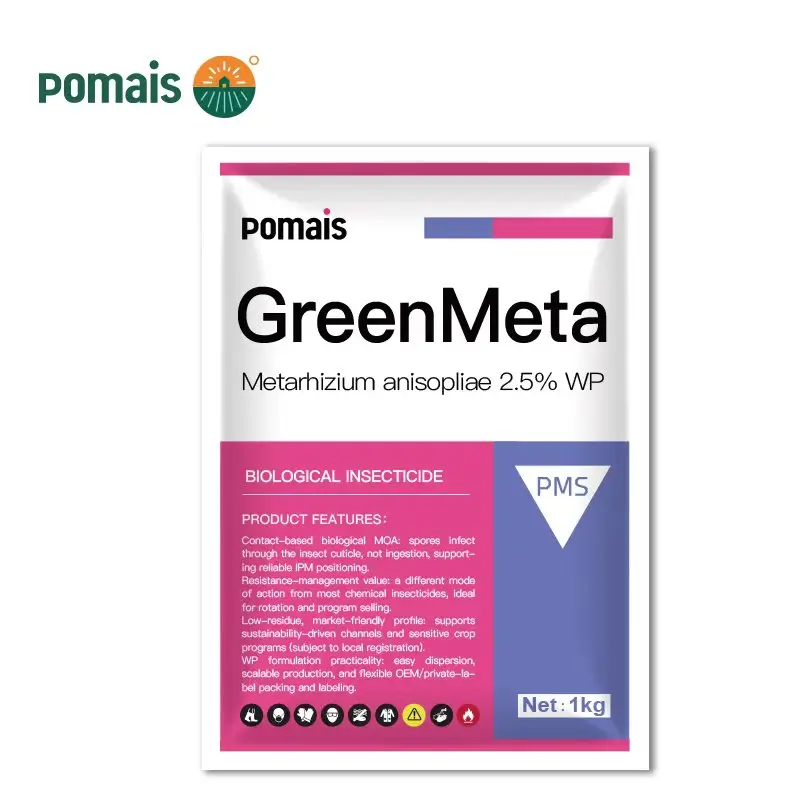

Available with COA/MSDS per batch, multilingual GHS artwork, and OEM/private-label packaging to meet market needs.

Traceability you can audit

Lot/expiry on pack and documents; units aligned (w/w) across label, spec, COA/MSDS for clean compliance checks.

Clear compliance positioning

Professional product—use strictly according to the local registered label, REI/PHI, and environmental safeguards.

Physical–Chemical & COA Snapshot

Built to make quality visible. Each batch of Tebufenpyrad 20% WP (200 g/kg, w/w) ships with a COA confirming the key parameters that drive mixing, coverage, and consistency in the field.

What we verify at release (COA-driven):

| Parameter | Spec focus (typical on COA) | Why it matters in use |

|---|---|---|

| Assay (w/w) | 20% (within release tolerance) | Confirms active content aligns with label and program design. |

| pH (slurry) | Within defined window | Supports product stability and compatibility in spray water. |

| Suspensibility (%) | Meets/Exceeds minimum | Keeps actives evenly suspended—uniform deposition on leaves. |

| Wetting time (s) | Fast wetting target | Quick wetting = faster mixing and turnaround in the field. |

| Wet sieve residue | Low % over specified mesh | Controls oversized particles; reduces nozzle blockage risk. |

| Particle size profile (D50/D90) | Controlled distribution | Predictable dispersion and foliar coverage through calibrated nozzles. |

| Moisture (%) | Within window | Protects flow, prevents caking during storage and handling. |

| Bulk density | Documented (loose/packed) | Helps set dose-by-weight and carton/pallet planning. |

| Appearance | Consistent color/texture | Visual cue of batch uniformity; easy QC check on receipt. |

Note: Exact limits and methods are defined in the spec and shown on the COA for your lot.

Label & document alignment

- Units align as w/w across label, COA, MSDS, and spec sheet.

- Lot & expiry appear on both packaging and documents for full traceability.

- GHS-compliant labeling and controlled artwork versions streamline audits and registrations.

Rates & Application

Use strictly according to the registered label in your market. The guide below helps users prepare, mix, and apply Tebufenpyrad 20% WP for consistent field results while keeping compliance and worker safety front and center.

How to position a spray (simple, practical)

- Trigger: spray when scouting thresholds or local advisory levels are reached; treat hot spots early.

- Coverage goal: wet the leaf underside where mites shelter; maintain even canopy coverage.

- Intervals: follow label interval; don’t shorten with “low-and-often” sprays—use full labeled rate at the right timing.

Mixing & loading (WP best practice)

- Pre-check: clean tank, strainers, lines. Start agitation.

- Half-fill tank with clean water (pH 5–7 preferred).

- Slurry the WP (pre-mix) in a small bucket; pour through the tank screen.

- Add in order: WP/WDG → SC/SL → EC → adjuvants, keeping agitation on.

- Top up with water to volume; keep agitation running during spraying.

- If pausing, re-agitate before restarting (WP needs suspension).

- After spray: triple-rinse container; flush lines and nozzles.

Application technique (coverage = control)

- Nozzles: fine-to-medium droplets aimed into the underside of leaves; use air-assist or angled nozzles in dense canopies.

- Water volume: adjust to crop and canopy density to achieve full coverage (orchard/vine > field veg).

- Drift: avoid high wind; use drift-reduction tips where appropriate; respect buffer zones near water.

- Heat stress: avoid spraying during extreme heat or drought stress to reduce phytotoxicity risk.

Program rules (keep performance strong)

- Rotate MoA: alternate away from IRAC 21A within the season; limit total 21A uses.

- Tank mixes: only where permitted; jar-test first; ensure physical/emulsion stability.

- Records: log field, product, MoA, date, rate, and outcome for better rotations.

Label-driven rate snapshots (format & units)

Actual rates, intervals, and PHI are defined by your local label.

- Formulation unit: WP programs typically declare dose in g/ha (or g/100 L in some orchard labels).

- Interval: follow label; align with pest growth stage and pressure.

- PHI/REI: see label; observe worker entry and harvest timings.

Compatibility

Designed to fit real-world tank programs when used as directed.

- Jar test first: Check physical compatibility and leaf safety with your local water and adjuvants.

- Mixing order (best practice): Water → WP/WDG → SC/SL → EC → adjuvants. Maintain agitation throughout.

- Water quality: Aim for pH 5–7; avoid alkaline water that can reduce performance. Use an approved buffer/conditioner if needed.

- Do not mix with strong alkalis/oxidizers. Use caution with high oil or surfactant loads, especially in hot, dry weather.

- Hardware hygiene: Start with a clean tank, lines, and strainers; flush after use.

- Small-scale check: Treat a few plants/rows first to confirm no phytotoxicity under local conditions.

Safety & Environmental

Professional use only. Follow the registered label and local regulations.

- PPE: Chemical-resistant gloves, coveralls, boots, and eye/face protection; avoid inhaling spray mist.

- Environmental care: Toxic to aquatic organisms and bees—avoid spraying near water bodies or during bloom; establish buffer zones and reduce drift.

- Weather & drift: Do not apply in strong wind or right before heavy rain; use drift-reduction nozzles where appropriate.

- Storage: Keep sealed in a cool, dry, ventilated place away from food/feed and heat; observe lot/expiry.

- First aid (summary):

- Skin—wash with soap and water.

- Eyes—rinse for 15 minutes.

- Ingestion—do not induce vomiting; seek immediate medical help.

- Inhalation—move to fresh air and obtain medical advice.

- REI/PHI: Observe worker re-entry and pre-harvest intervals per your local label.

Docs & Compliance Kit

Everything you need for listing, audits, and registrations—ready on request.

- COA & MSDS (per batch): Assay (w/w), identity, and physical–chemical checks with pass/fail vs. release specs.

- Spec sheet & methods: Test items, units, tolerances, and appearance notes aligned with the label.

- GHS labeling: Pictograms/statements, multilingual artwork, and version-controlled files.

- Traceability: Product name, assay, lot & expiry mirror across bottle/carton/docs.

- Registration support: Data summaries and optional accredited third-party testing.

OEM/Private Label & Packaging

Launch or refresh your brand with compliant, shelf-ready packs.

- Branding & artwork: Multilingual labels, barcodes/QR, lot & expiry printing; fast mockups from templates.

- WP packs (typical): 100 g / 250 g / 500 g / 1 kg foil pouches or multi-layer bags; moisture-barrier materials; desiccant options.

- Outer logistics: Export cartons with handling/orientation marks; pallet patterns optimized for container load.

- Documentation: COA/MSDS per batch; GHS artwork; carton markings matched to product and label codes.

- Commercials: Flexible private-label programs with stable lead times and market-fit sizes.

Why Choose POMAIS

Scale with a partner focused on quality, compliance, and speed to market.

- Reliable manufacturing: ISO/GMP processes, tight assay control, and batch traceability.

- Fast documentation: COA/MSDS, spec sheets, and multilingual GHS artwork on demand.

- Operational certainty: Season capacity planning and export-ready packing for smooth deliveries.

- Program fit: Rotation-friendly product with practical mixing and coverage guidance.

- Commercial support: Responsive technical and sales teams to help configure rates, packs, and labels within local rules.

FAQs

1) Can I get a sample?

Yes—most samples under 100 g are free; courier costs apply.

2) What information do you need for a quote?

Product/formulation, pack size (e.g., 100 g / 250 g / 500 g / 1 kg), quantity, destination port, label language/branding, and any special requirements.

3) Is it compatible with other products?

Generally tank-mix friendly when used as directed—jar-test first and follow the mixing order and water-pH guidance.

4) How should I store it and what is the shelf life?

Store sealed in a cool, dry, ventilated place away from food/feed; use by the expiry date on pack and COA/MSDS.

5) What documents come with each batch?

COA & MSDS, spec sheet, and GHS artwork; registration support and optional third-party tests are available.

6) What about resistance management?

Rotate away from IRAC 21A within the season, use full label rates at the right timing, and integrate IPM tools.

Get Pricing & Samples

Tell us your product/formulation, pack size, quantity, destination port, and label language/branding. We’ll respond quickly with a tailored offer, documentation list, and sample options.