Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP

You are procuring a triple-mode wettable powder positioned for preventive to early-curative protection on label-listed crops where broad pathogen pressure threatens quality and yield. Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP gives you program flexibility: you deploy it at disease-conducive windows to cover diverse complexes while distributing resistance pressure across P07 / 1 / 11. The outcome you are buying is simple—wide-spectrum coverage in one SKU, clean deposits, and a rotation-friendly profile that slots into professional schedules without operational recipes on the public page. All crops, targets, intervals, PHI/REI, protected vs. open-field permissions, and mixing policies are label-dependent. Use only as per the approved local label, with trained personnel and PPE per SDS/SOP.

- Designed for Professional Buyers & Bulk Orders

- This product is available for business purchase and large-scale distribution.

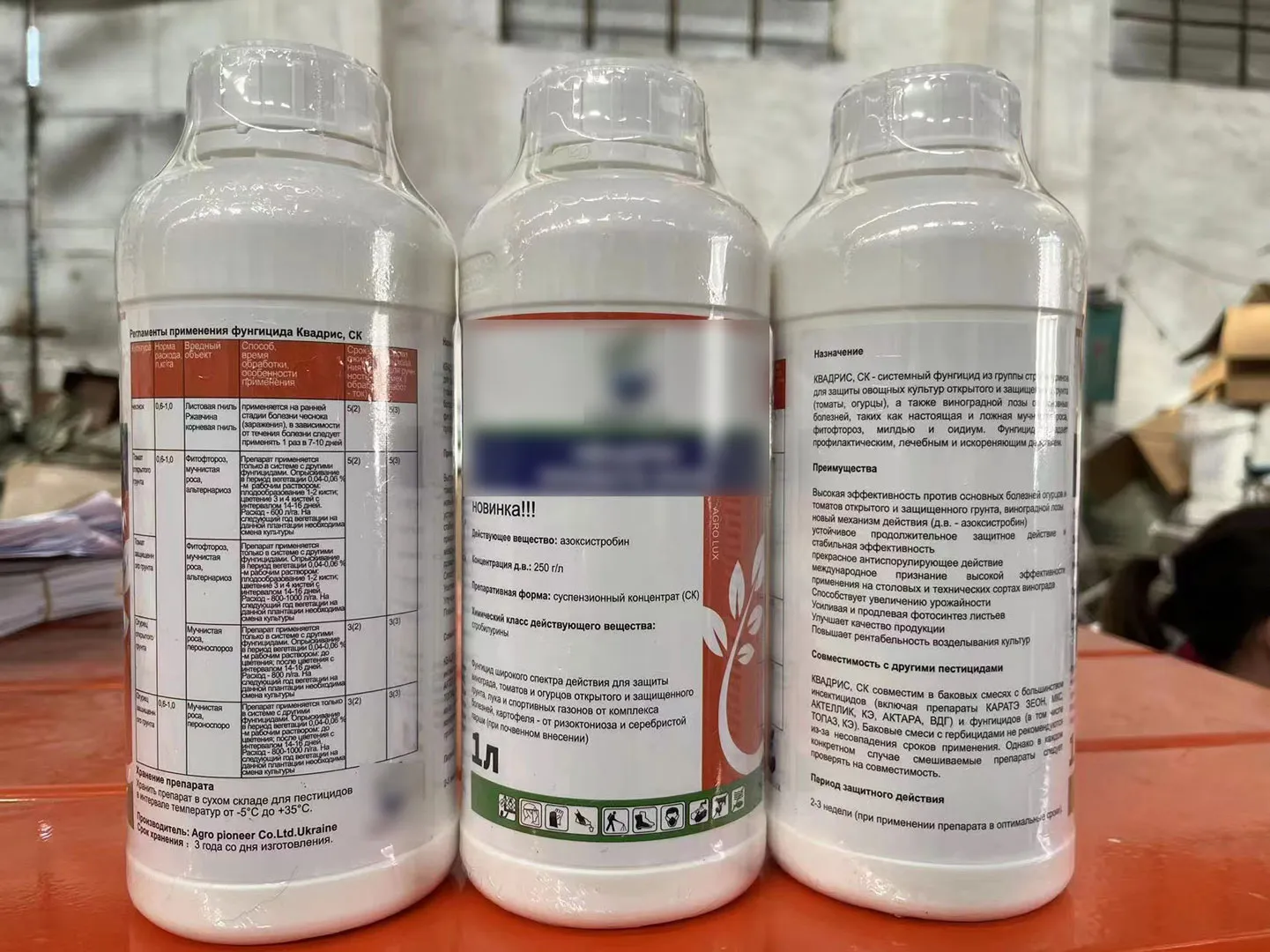

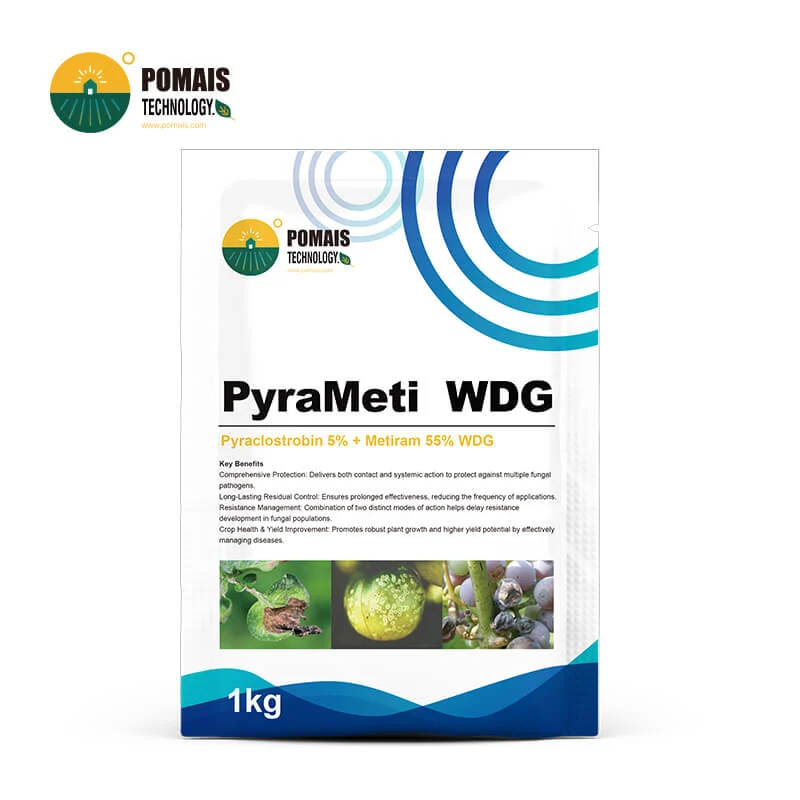

- We support custom packaging, labeling, and formulation to meet your market needs.

- Let’s build your brand together.

About Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP

About Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP

| Item | Specification |

|---|---|

| Product | Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP |

| Class / FRAC | Triple-mode fungicide — P07 (fosetyl-Al), 1 (thiophanate-methyl), 11 (azoxystrobin) |

| Formulation | WP — wettable powder engineered for fast wetting & stable suspension |

| Positioning | Preventive → early curative, rotation-friendly profile (label-dependent) |

| Movement (by active) | Fosetyl-Al: systemic, bidirectional; Thiophanate-methyl: upward systemic; Azoxystrobin: translaminar/xylem redistribution |

| Spectrum intent | Broad complexes where listed; program coverage across diverse pathogens (label-dependent) |

| Appearance | Free-flowing powder; controlled dust for cleaner induction |

| Packaging | 1 kg / 5 kg / 10 kg / 25 kg (market-dependent) |

| Documents | COA / SDS / TDS supplied per lot |

| Compliance | Professional use only. Use only as per the approved local label. All crops/targets/intervals/mixing policies are label-dependent. |

Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP | Triple-Mode Fungicide (P07/1/11)

Behind that simplicity, each active plays a defined role in your program. Fosetyl-aluminum (P07) delivers systemic, bidirectional movement and host-defense support, strengthening performance in disease-conducive periods and complementing non-phosphonate partners. Thiophanate-methyl (FRAC 1) contributes upward systemic protection through mitosis inhibition, supporting curative reach when coverage is timely—managed carefully because FRAC 1 carries known resistance risk in several pathosystems. Azoxystrobin (FRAC 11) adds strong preventive activity via QoI respiration inhibition with translaminar/xylem redistribution, improving protection on exposed tissues when deposit quality is high. The WP platform is engineered for fast wetting, stable suspension, and controlled dust to keep spray performance consistent across long shifts. Stewardship remains non-negotiable: rotate away from FRAC 1/11 as your label permits, keep sanitation and microclimate controls active, and document block-level decisions for audit readiness.

Composition & Mode of Action

You are buying triple-mode protection in one SKU. Fosetyl-aluminum (P07) brings systemic, bidirectional movement and host-defense support; thiophanate-methyl (FRAC 1) adds upward systemic mitosis inhibition; azoxystrobin (FRAC 11) delivers preventive QoI respiration inhibition with translaminar/xylem redistribution. You deploy this mix preventively to early-curative and rotate away from FRAC 1/11 as your label permits. All uses are label-dependent.

Fosetyl-aluminum (30%) — P07

- Role: systemic, bidirectional movement (acropetal + basipetal) supporting oomycete coverage where listed and host-defense activation (program resilience).

- Outcome: steadies performance during disease-conducive periods and complements partners that lack deep systemic redistribution.

- Placement: preventive timing with strong sanitation/microclimate discipline; pairs well with QoI/MBC partners in rotation (label-dependent).

Thiophanate-methyl (30%) — FRAC 1 (MBC)

- Role: upward systemic benzimidazole that inhibits mitosis (microtubule assembly); historically broad utility.

- Outcome: supports early curative reach when deposits are timely and even.

- Stewardship: known resistance risk in several pathosystems; avoid back-to-back FRAC 1 exposures and rotate per program rules.

Azoxystrobin (5%) — FRAC 11 (QoI)

- Role: respiration inhibitor (Qo site) with translaminar/xylem movement; strong preventive activity across many listed pathogens.

- Outcome: improves protection on exposed surfaces and newly expanded tissues when spray quality is high.

- Stewardship: manage FRAC 11 exposure; integrate non-chemical controls and rotate to non-11 groups (label-dependent).

Why this premix works for you

- Spectrum complementarity: P07 (systemic + defense support) + 1 (mitosis) + 11 (respiration) broadens program coverage.

- Movement architecture: bidirectional + upward systemic + translaminar/xylem helps protect multiple tissue zones—provided deposit quality is maintained.

- Resistance pressure distribution: three modes share load, but FRAC 1/11 still require disciplined rotation and interval integrity.

Use Scenarios (label-dependent)

You deploy Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP preventively or at first sign across label-listed segments—cereals (incl. wheat), vegetables, fruit & vines, and ornamentals/greenhouse—to protect finish and yield while distributing resistance pressure across P07/1/11. Rotate away from FRAC 1/11 as your label permits.

Cereals (incl. wheat) — where permitted

- Windows: tillering → flag leaf → quality-hold phases, aligned to your label.

- Targets (label-dependent): listed leaf/ear diseases; program support where oomycete pressure or complex disease environments occur.

- Operational focus: coverage on upper leaves/ears; stage blocks to match harvest plan; maintain droplet spectra and interval integrity.

- Stewardship: rotate out of FRAC 1/11 after the planned exposure window; keep sanitation and residue management active.

Vegetables

- Windows: canopy closure; humidity-prone growth stages; pre-harvest appearance holds where listed.

- Targets (label-dependent): listed foliar/fruit rots and leaf spots under conducive weather.

- Operational focus: even deposits into dense canopies; irrigation discipline to reduce leaf-wetness duration; verify coverage on undersides.

- Stewardship: shorten FRAC 1/11 exposure in high-risk crops/regions; document partners and intervals.

Fruit & Vines

- Windows: bloom → fruit set/cluster development → pre-harvest quality holds, per label.

- Targets (label-dependent): listed blossom/fruit diseases in complex microclimates.

- Operational focus: clean deposits on blossoms, calyx, cluster interiors; integrate canopy/airflow management to support contact components.

- Stewardship: rotation away from FRAC 1/11; non-chemical hygiene between passes.

Ornamentals / Greenhouse Production

- Windows: finishing stages and humidity swings that threaten sell-through.

- Targets (label-dependent): listed foliar/blossom pathogens in susceptible species.

- Operational focus: spacing, airflow, bench/tool hygiene; verify coverage on delicate tissues without exceeding label directions.

- Stewardship: apply only where protected-structure use is approved; trained personnel and PPE per SDS/SOP.

Formulation & Handling (WP)

You run Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP as a fast-wetting, stable-suspension wettable powder that builds uniform slurries, protects nozzles, and keeps spray quality consistent across long shifts—use only as per the approved local label.

Wetting & dispersion

- Engineered for rapid wetting and quick break into a uniform slurry, reducing induction time and batch variability.

- Controlled dust at load-in improves operator hygiene and weighing accuracy.

Suspension & agitation

- Holds a stable suspension under standard agitation; brief recirculation restores homogeneity after short holds.

- Particle-size distribution tuned to limit sieve residue and maintain pattern stability.

Induction & filtration discipline

- Use dedicated induction hoppers; maintain a steady liquid vortex to prevent dry bridging.

- Fit appropriate strainers/filters per your SOP; verify mesh size to protect nozzles on long runs.

Spray quality & deposition

- Target uniform droplet spectra for even deposits across blossoms, calyx, cluster interiors, dense foliage, and ears/flag leaves where listed.

- Calibrate pumps/meters; track pressure and flow to avoid drift-prone fines or under-coverage.

Water quality & partners

- Start with clean water; align pH/hardness ranges with your internal SOP.

- Consider partners only if the approved local label permits—run a jar test before pilot use.

Storage & hygiene

- Store sealed, cool, dry; keep pallets upright and protected from moisture.

- Execute full clean-out of tanks/lines/filters; handle rinsates under local regulations.

Program Fit & Resistance Stewardship

You position Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP preventively or at first sign, then rotate away from FRAC 1/11 on a fixed calendar. You stage blocks to match labor and harvest plans, keep sanitation and microclimate discipline active, and document intervals, partners, and weather for audit readiness—use only as per the approved local label.

Detailed Explanation

Calendar & rotation rules

- Pre-map disease-conducive windows by crop/region; slot this SKU early, then move off FRAC 1/11 to non-1/11 groups for the remainder of the period.

- Keep fosetyl-Al (P07) as the systemic/defense-support backbone within permitted sequences; avoid repeating FRAC 1 or FRAC 11 back-to-back.

Block staging & interval integrity

- Treat fields/blocks in harvest order to reduce rework and maintain interval integrity.

- Sync sprayer availability, crew shifts, and water points so interval drift does not erode performance or compliance.

Operational discipline

- Calibrate induction, agitation, filtration for slurry homogeneity; monitor pressure/flow to maintain droplet spectra and avoid drift-prone fines.

- Combine with sanitation, canopy/airflow, and irrigation timing to shorten leaf-wetness duration and raise the value of each exposure.

Records & governance

- Log lot codes, blocks, growth stages, partners, intervals, and weather; retain documentation with COA/SDS/TDS for audits.

- All sequences, intervals, partners, PHI/REI, and protected-structure permissions remain label-dependent.

QC & Stability

Every lot ships with COA / SDS / TDS and is release-tested for identity, wetting, suspensibility, and slurry quality. Stability programs and retention samples support shelf life and traceability.

Lot release controls (no public numeric limits)

- Assay/ID of each active; appearance of powder and slurry.

- Wetting time / dispersibility for predictable induction; suspensibility to ensure uniform deposits.

- Wet-sieve residue / PSD to protect nozzles and pattern.

- pH (slurry) / density / foam tendency for metering and reading accuracy.

Stability & retention

- Accelerated and real-time stability underpin shelf life and pack compatibility.

- Retention samples archived per lot; end-to-end traceability from inputs to finished packs.

Receiving QA & documentation

- Verify tamper evidence, labels, lot codes, and COA match; run a small slurry clarity check if your SOP requires it.

- Store sealed, cool, and dry; segregate by lot and record storage locations.

OEM & Compliance

You can private-label this triple-mode WP with multilingual artwork, serialization, and export-ready packs—while keeping all claims and site permissions strictly label-dependent.

Private label & artwork

- Multilingual labels (EN/ES/FR/AR/RU/PT, etc.), serialization/barcodes, optional QR e-leaflet.

- Brand styling without compromising mandatory hazard, stewardship, and claim language.

Packaging & palletization

- 1 / 5 / 10 / 25 kg (market-dependent) in HDPE-lined bags or fiber drums.

- Export-grade cartons and pallet schemes optimized for container utilization; master data (SKU codes, dimensions, net/gross weights) available for ERP onboarding.

Regulatory alignment

- All crops, pathogens, PHI/REI, intervals, mixing policies, and protected-structure permissions are market-specific.

- Final text and pictograms aligned to local frameworks; professional use only and SDS/SOP alignment are mandatory.

Deliverables

- COA / SDS / TDS per lot; editable dielines and print-ready PDFs on request; palletization proposals for export planning.

FAQ

Q1. What FRAC codes are in this SKU?

P07 / 1 / 11—fosetyl-Al, thiophanate-methyl, and azoxystrobin.

Q2. Preventive or curative?

Preventive → early curative within label allowances; coverage and timing drive outcomes.

Q3. How do you manage resistance?

Rotate away from FRAC 1/11, avoid back-to-back sequences, and consider partners only if the approved local label permits.

Q4. Is greenhouse use allowed?

Only where approved local labels permit; follow site-specific intervals and REI/PHI.

Q5. What documents ship with each lot?

COA / SDS / TDS; OEM artwork and packaging specs are available on request.

Q6. Pack sizes available?

Typically 1 / 5 / 10 / 25 kg (market-dependent); palletization data supplied for export planning.

Request the specification pack for Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP—COA/SDS/TDS templates, stability summary, label/carton dielines, and a packaging proposal.

To accelerate quoting, share your target markets, crops & sites (greenhouse/open field), label languages, preferred pack sizes, and annual forecast. We will confirm MOQ, lead time, palletization, and artwork timelines—finalized against your approved local label.

| Item | Specification |

|---|---|

| Product | Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP |

| Class / FRAC | Triple-mode fungicide — P07 (fosetyl-Al), 1 (thiophanate-methyl), 11 (azoxystrobin) |

| Formulation | WP — wettable powder engineered for fast wetting & stable suspension |

| Positioning | Preventive → early curative, rotation-friendly profile (label-dependent) |

| Movement (by active) | Fosetyl-Al: systemic, bidirectional; Thiophanate-methyl: upward systemic; Azoxystrobin: translaminar/xylem redistribution |

| Spectrum intent | Broad complexes where listed; program coverage across diverse pathogens (label-dependent) |

| Appearance | Free-flowing powder; controlled dust for cleaner induction |

| Packaging | 1 kg / 5 kg / 10 kg / 25 kg (market-dependent) |

| Documents | COA / SDS / TDS supplied per lot |

| Compliance | Professional use only. Use only as per the approved local label. All crops/targets/intervals/mixing policies are label-dependent. |

Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP | Triple-Mode Fungicide (P07/1/11)

Behind that simplicity, each active plays a defined role in your program. Fosetyl-aluminum (P07) delivers systemic, bidirectional movement and host-defense support, strengthening performance in disease-conducive periods and complementing non-phosphonate partners. Thiophanate-methyl (FRAC 1) contributes upward systemic protection through mitosis inhibition, supporting curative reach when coverage is timely—managed carefully because FRAC 1 carries known resistance risk in several pathosystems. Azoxystrobin (FRAC 11) adds strong preventive activity via QoI respiration inhibition with translaminar/xylem redistribution, improving protection on exposed tissues when deposit quality is high. The WP platform is engineered for fast wetting, stable suspension, and controlled dust to keep spray performance consistent across long shifts. Stewardship remains non-negotiable: rotate away from FRAC 1/11 as your label permits, keep sanitation and microclimate controls active, and document block-level decisions for audit readiness.

Composition & Mode of Action

You are buying triple-mode protection in one SKU. Fosetyl-aluminum (P07) brings systemic, bidirectional movement and host-defense support; thiophanate-methyl (FRAC 1) adds upward systemic mitosis inhibition; azoxystrobin (FRAC 11) delivers preventive QoI respiration inhibition with translaminar/xylem redistribution. You deploy this mix preventively to early-curative and rotate away from FRAC 1/11 as your label permits. All uses are label-dependent.

Fosetyl-aluminum (30%) — P07

- Role: systemic, bidirectional movement (acropetal + basipetal) supporting oomycete coverage where listed and host-defense activation (program resilience).

- Outcome: steadies performance during disease-conducive periods and complements partners that lack deep systemic redistribution.

- Placement: preventive timing with strong sanitation/microclimate discipline; pairs well with QoI/MBC partners in rotation (label-dependent).

Thiophanate-methyl (30%) — FRAC 1 (MBC)

- Role: upward systemic benzimidazole that inhibits mitosis (microtubule assembly); historically broad utility.

- Outcome: supports early curative reach when deposits are timely and even.

- Stewardship: known resistance risk in several pathosystems; avoid back-to-back FRAC 1 exposures and rotate per program rules.

Azoxystrobin (5%) — FRAC 11 (QoI)

- Role: respiration inhibitor (Qo site) with translaminar/xylem movement; strong preventive activity across many listed pathogens.

- Outcome: improves protection on exposed surfaces and newly expanded tissues when spray quality is high.

- Stewardship: manage FRAC 11 exposure; integrate non-chemical controls and rotate to non-11 groups (label-dependent).

Why this premix works for you

- Spectrum complementarity: P07 (systemic + defense support) + 1 (mitosis) + 11 (respiration) broadens program coverage.

- Movement architecture: bidirectional + upward systemic + translaminar/xylem helps protect multiple tissue zones—provided deposit quality is maintained.

- Resistance pressure distribution: three modes share load, but FRAC 1/11 still require disciplined rotation and interval integrity.

Use Scenarios (label-dependent)

You deploy Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP preventively or at first sign across label-listed segments—cereals (incl. wheat), vegetables, fruit & vines, and ornamentals/greenhouse—to protect finish and yield while distributing resistance pressure across P07/1/11. Rotate away from FRAC 1/11 as your label permits.

Cereals (incl. wheat) — where permitted

- Windows: tillering → flag leaf → quality-hold phases, aligned to your label.

- Targets (label-dependent): listed leaf/ear diseases; program support where oomycete pressure or complex disease environments occur.

- Operational focus: coverage on upper leaves/ears; stage blocks to match harvest plan; maintain droplet spectra and interval integrity.

- Stewardship: rotate out of FRAC 1/11 after the planned exposure window; keep sanitation and residue management active.

Vegetables

- Windows: canopy closure; humidity-prone growth stages; pre-harvest appearance holds where listed.

- Targets (label-dependent): listed foliar/fruit rots and leaf spots under conducive weather.

- Operational focus: even deposits into dense canopies; irrigation discipline to reduce leaf-wetness duration; verify coverage on undersides.

- Stewardship: shorten FRAC 1/11 exposure in high-risk crops/regions; document partners and intervals.

Fruit & Vines

- Windows: bloom → fruit set/cluster development → pre-harvest quality holds, per label.

- Targets (label-dependent): listed blossom/fruit diseases in complex microclimates.

- Operational focus: clean deposits on blossoms, calyx, cluster interiors; integrate canopy/airflow management to support contact components.

- Stewardship: rotation away from FRAC 1/11; non-chemical hygiene between passes.

Ornamentals / Greenhouse Production

- Windows: finishing stages and humidity swings that threaten sell-through.

- Targets (label-dependent): listed foliar/blossom pathogens in susceptible species.

- Operational focus: spacing, airflow, bench/tool hygiene; verify coverage on delicate tissues without exceeding label directions.

- Stewardship: apply only where protected-structure use is approved; trained personnel and PPE per SDS/SOP.

Formulation & Handling (WP)

You run Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP as a fast-wetting, stable-suspension wettable powder that builds uniform slurries, protects nozzles, and keeps spray quality consistent across long shifts—use only as per the approved local label.

Wetting & dispersion

- Engineered for rapid wetting and quick break into a uniform slurry, reducing induction time and batch variability.

- Controlled dust at load-in improves operator hygiene and weighing accuracy.

Suspension & agitation

- Holds a stable suspension under standard agitation; brief recirculation restores homogeneity after short holds.

- Particle-size distribution tuned to limit sieve residue and maintain pattern stability.

Induction & filtration discipline

- Use dedicated induction hoppers; maintain a steady liquid vortex to prevent dry bridging.

- Fit appropriate strainers/filters per your SOP; verify mesh size to protect nozzles on long runs.

Spray quality & deposition

- Target uniform droplet spectra for even deposits across blossoms, calyx, cluster interiors, dense foliage, and ears/flag leaves where listed.

- Calibrate pumps/meters; track pressure and flow to avoid drift-prone fines or under-coverage.

Water quality & partners

- Start with clean water; align pH/hardness ranges with your internal SOP.

- Consider partners only if the approved local label permits—run a jar test before pilot use.

Storage & hygiene

- Store sealed, cool, dry; keep pallets upright and protected from moisture.

- Execute full clean-out of tanks/lines/filters; handle rinsates under local regulations.

Program Fit & Resistance Stewardship

You position Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP preventively or at first sign, then rotate away from FRAC 1/11 on a fixed calendar. You stage blocks to match labor and harvest plans, keep sanitation and microclimate discipline active, and document intervals, partners, and weather for audit readiness—use only as per the approved local label.

Detailed Explanation

Calendar & rotation rules

- Pre-map disease-conducive windows by crop/region; slot this SKU early, then move off FRAC 1/11 to non-1/11 groups for the remainder of the period.

- Keep fosetyl-Al (P07) as the systemic/defense-support backbone within permitted sequences; avoid repeating FRAC 1 or FRAC 11 back-to-back.

Block staging & interval integrity

- Treat fields/blocks in harvest order to reduce rework and maintain interval integrity.

- Sync sprayer availability, crew shifts, and water points so interval drift does not erode performance or compliance.

Operational discipline

- Calibrate induction, agitation, filtration for slurry homogeneity; monitor pressure/flow to maintain droplet spectra and avoid drift-prone fines.

- Combine with sanitation, canopy/airflow, and irrigation timing to shorten leaf-wetness duration and raise the value of each exposure.

Records & governance

- Log lot codes, blocks, growth stages, partners, intervals, and weather; retain documentation with COA/SDS/TDS for audits.

- All sequences, intervals, partners, PHI/REI, and protected-structure permissions remain label-dependent.

QC & Stability

Every lot ships with COA / SDS / TDS and is release-tested for identity, wetting, suspensibility, and slurry quality. Stability programs and retention samples support shelf life and traceability.

Lot release controls (no public numeric limits)

- Assay/ID of each active; appearance of powder and slurry.

- Wetting time / dispersibility for predictable induction; suspensibility to ensure uniform deposits.

- Wet-sieve residue / PSD to protect nozzles and pattern.

- pH (slurry) / density / foam tendency for metering and reading accuracy.

Stability & retention

- Accelerated and real-time stability underpin shelf life and pack compatibility.

- Retention samples archived per lot; end-to-end traceability from inputs to finished packs.

Receiving QA & documentation

- Verify tamper evidence, labels, lot codes, and COA match; run a small slurry clarity check if your SOP requires it.

- Store sealed, cool, and dry; segregate by lot and record storage locations.

OEM & Compliance

You can private-label this triple-mode WP with multilingual artwork, serialization, and export-ready packs—while keeping all claims and site permissions strictly label-dependent.

Private label & artwork

- Multilingual labels (EN/ES/FR/AR/RU/PT, etc.), serialization/barcodes, optional QR e-leaflet.

- Brand styling without compromising mandatory hazard, stewardship, and claim language.

Packaging & palletization

- 1 / 5 / 10 / 25 kg (market-dependent) in HDPE-lined bags or fiber drums.

- Export-grade cartons and pallet schemes optimized for container utilization; master data (SKU codes, dimensions, net/gross weights) available for ERP onboarding.

Regulatory alignment

- All crops, pathogens, PHI/REI, intervals, mixing policies, and protected-structure permissions are market-specific.

- Final text and pictograms aligned to local frameworks; professional use only and SDS/SOP alignment are mandatory.

Deliverables

- COA / SDS / TDS per lot; editable dielines and print-ready PDFs on request; palletization proposals for export planning.

FAQ

Q1. What FRAC codes are in this SKU?

P07 / 1 / 11—fosetyl-Al, thiophanate-methyl, and azoxystrobin.

Q2. Preventive or curative?

Preventive → early curative within label allowances; coverage and timing drive outcomes.

Q3. How do you manage resistance?

Rotate away from FRAC 1/11, avoid back-to-back sequences, and consider partners only if the approved local label permits.

Q4. Is greenhouse use allowed?

Only where approved local labels permit; follow site-specific intervals and REI/PHI.

Q5. What documents ship with each lot?

COA / SDS / TDS; OEM artwork and packaging specs are available on request.

Q6. Pack sizes available?

Typically 1 / 5 / 10 / 25 kg (market-dependent); palletization data supplied for export planning.

Request the specification pack for Fosetyl-aluminum 30% + Thiophanate-methyl 30% + Azoxystrobin 5% WP—COA/SDS/TDS templates, stability summary, label/carton dielines, and a packaging proposal.

To accelerate quoting, share your target markets, crops & sites (greenhouse/open field), label languages, preferred pack sizes, and annual forecast. We will confirm MOQ, lead time, palletization, and artwork timelines—finalized against your approved local label.