Metalaxyl vs Metalaxyl-M

What’s the Difference Between Metalaxyl and Metalaxyl-M?

The main difference between metalaxyl and metalaxyl-M is their isomer composition and resulting biological activity.

Metalaxyl is a racemic mixture containing both R- and S-enantiomers, while metalaxyl-M (also called mefenoxam) is an enriched form that contains predominantly the more active R-enantiomer — providing greater fungicidal efficacy at lower application rates.

If you are an importer, distributor, or brand owner comparing these two fungicides for your product portfolio, you need to clearly understand how this difference impacts both field performance and regulatory compliance.

Metalaxyl, first developed in the late 1970s, is a broad-spectrum systemic fungicide belonging to the phenylamide group. Its mode of action targets RNA synthesis in Oomycete fungi, making it effective against diseases like downy mildew and late blight. However, the standard metalaxyl formulation is a racemic mixture — meaning it contains equal parts of R- and S-isomers. Only the R-isomer is biologically active against pathogens, while the S-isomer has minimal effect.

Metalaxyl-M, often referred to by its trade name mefenoxam, is an improved version of metalaxyl produced through isomer enrichment techniques. This means it contains a significantly higher proportion (typically over 80–90%) of the active R-enantiomer. The practical benefit for your downstream customers is simple: better disease control with less active ingredient per hectare.

How does this difference help your business?

- Importers and brand owners can offer growers a more efficient option that aligns with stricter residue limits and sustainable use requirements.

- Distributors can reduce per-hectare product volume, which saves on logistics and storage.

- Retailers and agronomy advisors have a stronger story to market — emphasizing improved bioavailability and environmental performance.

Here’s a simple table to help you explain the key technical differences when presenting options to your buyers or local distributors:

| Aspect | Metalaxyl | Metalaxyl-M (Mefenoxam) |

|---|---|---|

| Isomer Content | Racemic mixture (R + S) | Enriched R-enantiomer |

| Biological Activity | Standard | Higher (more efficient at lower rates) |

| Typical Application Rate | Higher | Lower |

| Market Trend | Traditional registrations | Preferred in modern registrations |

By clearly showing the difference between metalaxyl and metalaxyl-M, you help your customers choose the right product for their crops, market requirements, and sustainability goals.

Why Choose Metalaxyl-M Over Metalaxyl?

You should choose metalaxyl-M instead of standard metalaxyl when you want stronger fungicidal activity with lower application rates, better residue management, and improved regulatory acceptance.

Many importers and brand owners now prefer metalaxyl-M for markets that demand modern, more sustainable formulations.

If you supply fungicide products to regions where resistance management, export residue limits, and sustainability claims are key selling points, offering metalaxyl-M can strengthen your market position.

Here’s why many importers and distributors make the switch:

- Higher bioavailability: Because metalaxyl-M is enriched with the active R-isomer, it delivers better systemic movement within plant tissues and more consistent disease control compared to the racemic metalaxyl. This means your growers can rely on fewer repeat applications.

- Lower dose required: In practice, you often need 20–30% less active ingredient to achieve the same or better control of Oomycete diseases. This reduction helps you stand out in sustainability-focused tenders or for buyers with MRL-sensitive export crops.

- Residue management: Many export markets, especially the EU, have tightened MRLs for phenylamide fungicides. By supplying metalaxyl-M, you make it easier for your retail partners and growers to stay compliant with these limits.

- Regulatory advantage: In several countries, new registrations now favor metalaxyl-M over standard metalaxyl because the lower environmental load and improved toxicological profile are easier to justify in the dossier. If you plan to expand your portfolio into markets with stricter re-registration cycles, metalaxyl-M gives you a clear edge.

A distributor supplying seed treatment products for potatoes and vegetables can use metalaxyl-M to position their brand as modern and export-friendly — something that’s increasingly important as global buyers look for “cleaner” supply chains. Similarly, brand owners marketing ready-mix fungicide combos can highlight that metalaxyl-M allows lower total a.i. without sacrificing performance.

In short, when you compare metalaxyl vs metalaxyl-M, your choice affects not just how well the product works in the field, but how easy it is for your clients to comply with regulations, maintain quality exports, and promote a sustainability story that growers trust.

Typical Uses & Crops – Metalaxyl vs Metalaxyl-M

Both metalaxyl and metalaxyl-M are widely used to control Oomycete fungi such as downy mildew, late blight, and damping-off in crops like potatoes, grapes, vegetables, and rice.

Choosing between them depends on your target crop, resistance concerns, and your customers’ preference for higher efficacy at lower doses.

When you supply fungicides based on metalaxyl or metalaxyl-M, it’s critical to help your distributors and retail partners understand which crops and disease pressures each active ingredient works best for.

Core crops and disease targets:

- Potatoes & tomatoes: Late blight (Phytophthora infestans) control is one of the classic uses for both actives. Many growers now prefer metalaxyl-M because they get better systemic protection with less residue risk.

- Grapes: Metalaxyl and metalaxyl-M are common options for downy mildew (Plasmopara viticola). Metalaxyl-M’s improved bioavailability makes it a strong choice for export-focused vineyards with strict residue standards.

- Vegetables & leafy greens: Good for damping-off (Pythium spp.) and downy mildew on crops like onions, cucumbers, and spinach.

- Rice: In Asia, metalaxyl and metalaxyl-M formulations are used to manage downy mildew and leaf blight in paddy fields — with metalaxyl-M increasingly favored for its lower application rate.

How importers and distributors can guide usage:

Your field teams should explain that while both actives are systemic and work through root uptake and translocation, metalaxyl-M’s higher proportion of the active R-isomer means farmers may see longer residual protection. This can reduce the number of repeat sprays needed in a season.

A distributor selling to potato growers can recommend metalaxyl-M seed treatment to protect seedlings from soil-borne pathogens like Pythium and Phytophthora. This approach is often paired with foliar sprays in high-risk conditions.

While cost-sensitive markets may still buy standard metalaxyl, brand owners positioning their product lines as premium and export-ready will often choose metalaxyl-M. Your job is to help buyers understand how local disease pressure, residue limits, and resistance management factor into the decision.

Formulation Types & Compatibility

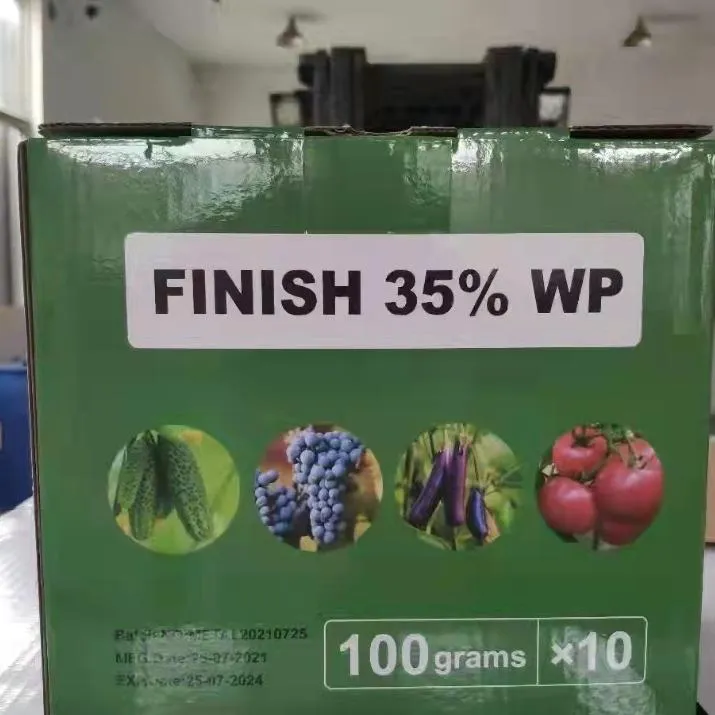

Metalaxyl and metalaxyl-M are available in similar formulation types — such as WP (wettable powder), FS (flowable concentrate for seed treatment), EC (emulsifiable concentrate), and GR (granules) — but metalaxyl-M is often preferred for seed treatment or premium blends because of its higher biological activity.

When you supply metalaxyl or metalaxyl-M products, your distributors, retailers, or farm service teams need to know how each formulation type fits different crops and application methods. Both active ingredients belong to the phenylamide fungicide group and work systemically, but their performance depends on how you deliver them to the plant.

Common formulation types include:

- WP (Wettable Powder): Often used for foliar sprays to control downy mildew or late blight in crops like grapes, potatoes, and vegetables. Both metalaxyl and metalaxyl-M can be offered in this form, depending on your market’s demand for price or performance.

- FS (Flowable Concentrate for Seed Treatment): Metalaxyl-M is popular for seed treatment because its higher R-isomer content provides stronger protection against soil-borne pathogens like Pythium and Phytophthora at lower use rates.

- EC (Emulsifiable Concentrate): Sometimes used for soil or foliar applications, especially where tank-mixing with other products is common.

- GR (Granules): Applied directly to soil for root uptake in certain crops such as rice.

Compatibility is also important. Many importers and brand owners combine metalaxyl or metalaxyl-M with other fungicides like mancozeb, chlorothalonil, or copper-based products to broaden the spectrum and delay resistance. When your buyers develop ready-mix products, metalaxyl-M’s lower dosage can help them keep total active ingredient load within regulatory limits.

Here’s a simple table to help you and your buyers see the typical use by formulation type:

| Formulation | Typical Use | Metalaxyl | Metalaxyl-M |

|---|---|---|---|

| WP | Foliar spray for downy mildew, late blight | ✓ | ✓ |

| FS | Seed treatment for Pythium, Phytophthora | ✓ | ✓ (preferred) |

| EC | Soil or foliar application, tank-mix | ✓ | ✓ |

| GR | Soil treatment, rice paddies | ✓ | ✓ |

When positioning your portfolio, be ready to explain which formulations make the most sense for local farming practices and your market’s regulatory landscape.

Regulatory Compliance & Market Preferences

Metalaxyl-M is generally favored over standard metalaxyl in many markets today because its lower application rates and improved toxicological profile help importers, distributors, and brand owners align with stricter residue limits and sustainability requirements.

If you are an importer, brand owner, or registration consultant, it’s critical to understand how regulatory trends influence the choice between metalaxyl and metalaxyl-M. Both active ingredients belong to the same chemical group, but the market trend is clear: regulators in key export regions increasingly prefer the more efficient isomer-enriched version.

Many countries, especially in the European Union and parts of Asia-Pacific, have tightened residue limits for phenylamide fungicides. Metalaxyl-M’s higher proportion of the active R-isomer means that growers can achieve effective disease control with 20–30% less active ingredient per hectare, helping to keep residues below maximum residue limits (MRLs).

This difference is not just about performance in the field — it affects your ability to maintain product registrations or secure new approvals. In some jurisdictions, older racemic metalaxyl registrations face more frequent re-evaluation or are phased out altogether in favor of metalaxyl-M. For brand owners, this means that investing in metalaxyl-M-based formulations can reduce the risk of future regulatory obstacles and costly reformulations.

For example, a distributor supplying fungicides for vegetable exporters may find that metalaxyl-M offers a practical advantage for growers who supply EU supermarket chains with strict residue compliance programs. Similarly, seed treatment products formulated with metalaxyl-M can help meet modern environmental guidelines that emphasize lower chemical input.

To ensure you stay ahead, always keep your registration dossiers up to date with clear information on isomer ratios, toxicology studies, and environmental impact data. This not only streamlines local re-registration but also strengthens your credibility with large retail buyers who increasingly audit pesticide sourcing for sustainability and compliance.

Understanding these regulatory differences allows you to plan your supply chain and marketing strategy with confidence — giving your customers products that are not only effective, but also future-ready.

Storage & Shelf Life Considerations

Both metalaxyl and metalaxyl-M have stable shelf lives when stored properly, but importers, distributors, and brand owners should always check batch traceability, packaging integrity, and updated certificates of analysis to ensure product quality throughout storage and transit.

For anyone handling bulk agrochemical shipments — whether you’re an importer, distributor, or brand owner — it’s not enough to know the active ingredient works well in the field. You also need to manage how metalaxyl and metalaxyl-M perform during transport, warehousing, and extended storage periods.

In general, both active ingredients remain stable for up to two years if kept sealed in original packaging under cool, dry, and well-ventilated conditions. However, several factors can affect real shelf life and product integrity:

- Temperature control: Extended exposure to high temperatures or direct sunlight can degrade the active content, especially in emulsifiable concentrates (EC). Always store drums or containers indoors, away from heat sources.

- Moisture risk: For wettable powder (WP) and granule (GR) formulations, excess humidity can cause caking or clumping, reducing ease of application. Use moisture-barrier packaging and secure pallets properly.

- Batch traceability: Importers should ensure that every shipment comes with batch numbers, COA (Certificate of Analysis), SDS (Safety Data Sheet), and, when applicable, third-party inspection reports. This helps you maintain traceability and meet any local or export audit requirements.

- Packaging quality: Well-sealed, chemical-resistant drums, bottles, or foil bags help maintain potency and prevent leaks during transport. Some markets may require child-proof caps or multi-language hazard labels to comply with local storage regulations.

A good practice for distributors is to rotate inventory using a clear FIFO (First In, First Out) system, so older stock is always sold or used first. This minimizes the risk of expired products reaching your end customers and protects your brand reputation.

Working with a reliable manufacturer also means you get storage guidelines, stability data, and support for any unexpected issues during warehousing or shipping. When buyers see that you can guarantee consistent quality, they know your metalaxyl or metalaxyl-M product line is not just competitive, but also dependable.

OEM Supply & Custom Formulation Options

Whether you’re sourcing metalaxyl or metalaxyl-M, partnering with a qualified OEM manufacturer allows you to customize formulation types, packaging, and regulatory documentation — helping importers, distributors, and brand owners adapt quickly to local market demands and compliance standards.

As an importer, distributor, or agrochemical brand owner, your success depends not only on the active ingredient but also on how your product is manufactured, packaged, and supported. Choosing the right OEM partner for metalaxyl and metalaxyl-M formulations gives you flexibility, efficiency, and peace of mind in highly regulated and competitive markets.

Key areas where OEM support adds real value:

- Custom formulations: Depending on your target crops and regional disease pressures, you may need standard formulations (e.g., 25% WP, 350 g/L EC) or specialized combinations (e.g., metalaxyl-M + mancozeb or metalaxyl-M + cymoxanil). A capable OEM can help you develop and test these mixtures efficiently.

- Packaging flexibility: Markets vary widely. You may need 100 mL retail bottles for smallholder farmers, 1-liter containers for agronomy suppliers, or 200-liter drums for bulk field use. OEM providers should offer customizable packaging solutions with multilingual labeling and branding.

- Regulatory documentation: OEM manufacturers with international experience should supply a full technical file — including COA, SDS, TDS, stability data, and assistance with registration dossiers. This is especially important if you’re working in markets like LATAM, Southeast Asia, or the EU where documentation is key to legal import and resale.

- Private label support: If you’re building a local or regional brand, your OEM should help you with brand-ready templates, QR-coded anti-counterfeit labels, and even marketing support materials when needed.

For example, if you’re launching a new metalaxyl-M seed treatment product, your OEM partner should be able to formulate to your specs, fill FS-type containers, and print your label in your local language — all while complying with your country’s pesticide packaging laws.

A well-structured OEM relationship also means faster production lead times, flexible MOQs, and better cost control — allowing you to respond faster to tender opportunities, seasonal demand spikes, or sudden regulation changes.

In short, whether you’re entering a new market or expanding your product line, having a responsive and capable OEM partner behind your metalaxyl and metalaxyl-M business gives you a competitive advantage — not just in product quality, but in execution.

Need a quote?

If you’re looking to strengthen your fungicide portfolio with reliable metalaxyl or metalaxyl-M solutions, now is the time to secure a supply chain that works for your business and your growers.

At POMAIS, we help importers, distributors, and brand owners source quality-verified active ingredients, develop custom formulations, and navigate complex regulatory requirements — so you can deliver consistent results, season after season.

Whether you need standard bulk formulations or premium metalaxyl-M for seed treatments and ready-mix blends, our team is ready to provide:

- Flexible OEM production and private labeling options

- Batch-tested product with full COA, SDS, and traceability support

- Packaging sizes that match your local market — from small retail bottles to large drums

- Responsive lead times and professional export handling

Reach out today to request a competitive quote, ask about our minimum order quantities, or discuss how we can help you adapt your product line for tomorrow’s sustainability and compliance needs.

Your customers expect reliable crop protection — and you deserve a trusted partner behind every order.

Hot Products

Hot news

Recommended news

FAQ