Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC

Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC is a program-ready systemic + multi-site protectant fungicide designed for oomycete pressure—notably downy mildew and late blight—in high-value vegetables and specialty crops. The stack combines Metalaxyl-M (FRAC 4) for systemic, translocated activity against oomycetes with Chlorothalonil (FRAC M05) for a broad, contact barrier that defends multiple infection points. In humid, rain-disrupted production where disease cycles re-ignite after every storm, this dual-pathway design helps stabilize outcomes by pairing curative reach with preventive coverage, supporting cleaner canopies across cucurbits, tomatoes, peppers, and watermelons—always within the scope of your registered product label.

- Designed for Professional Buyers & Bulk Orders

- This product is available for business purchase and large-scale distribution.

- We support custom packaging, labeling, and formulation to meet your market needs.

- Let’s build your brand together.

About Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC

About Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC

| Product | Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC |

| Actives (g/L) | Metalaxyl-M: 37.5 · Chlorothalonil: 500 |

| FRAC / MoA | FRAC 4 (phenylamide, systemic/oomycetes) + FRAC M05 (multi-site protectant, contact) |

| Formulation | SC — Suspension Concentrate |

| Appearance | Uniform, low-odor aqueous suspension (low settling; fast re-suspension) |

| Target Pathogens | Oomycetes: downy mildews / late blights / Phytophthora-type complexes (label-dependent) |

| Crop Scope (examples) | Cucurbits, tomato, pepper, watermelon (confirm local registration) |

| Quality Window | pH / viscosity / suspensibility / fineness within internal release ranges (range-based) |

| Stability | Cold/heat storage: Pass (validated protocol); shelf life per label under proper storage |

| Compliance Note | For licensed buyers; use strictly per the registered product label and local regulations |

| Documentation | COA, SDS, TDS, label elements (standard); registration dossier on request |

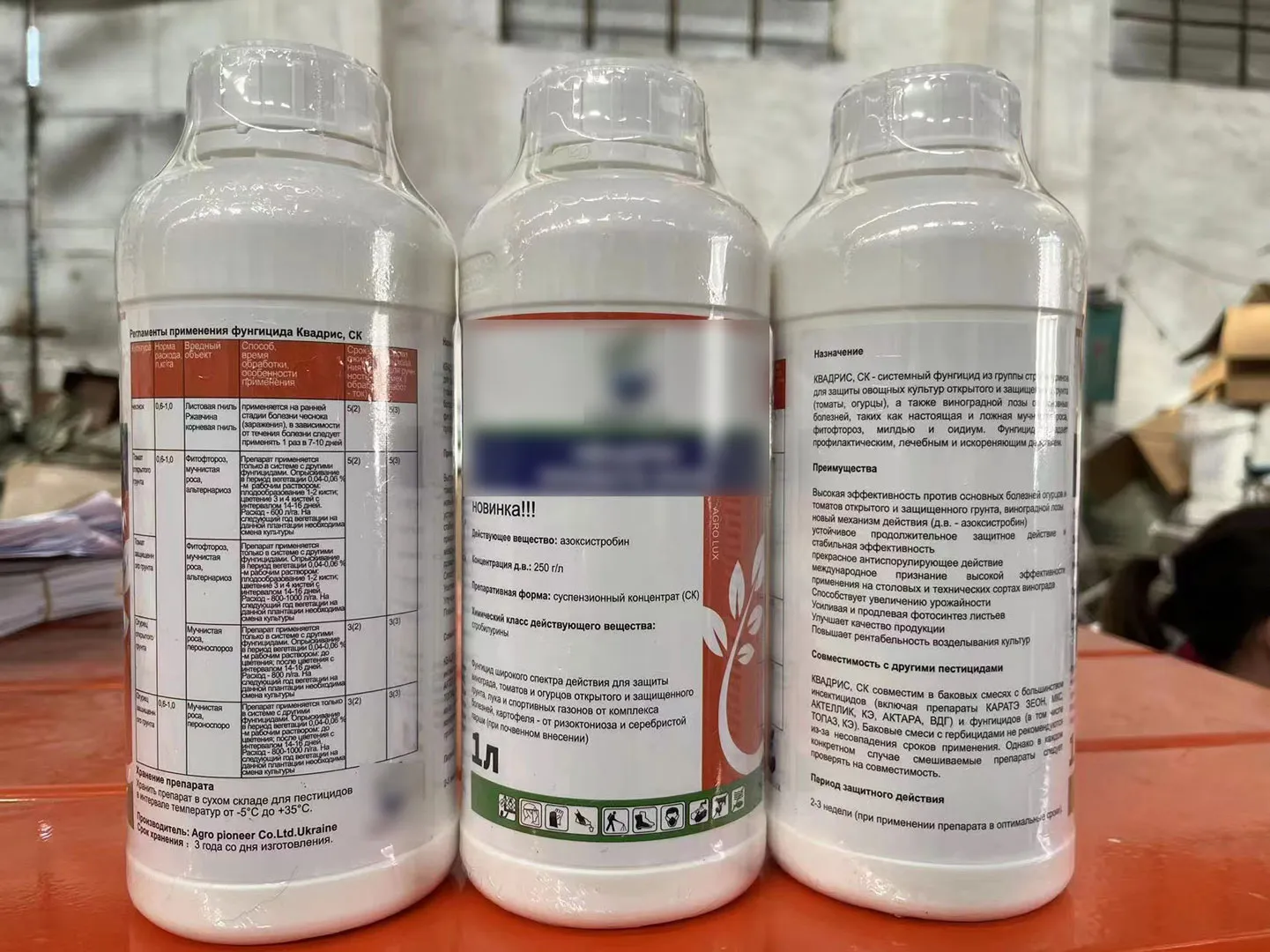

| Packaging (indicative) | Bottles 100 mL–1 L; cans 5–20 L; HDPE/PET with tamper-evident closures |

| Labeling / Languages | Multilingual artwork (EN/ES/FR/AR/RU; others on request); claims/legal alignment |

| Traceability & Security | Batch ID, QR traceability; optional anti-counterfeit (serialization/hologram) |

| Logistics Kit | Drop-tested cartons; pallet map (20GP/40HQ); packing list + SDS routing; shipment photo pack |

Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC (FRAC 4 + M05)

Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC is a program-ready systemic + multi-site protectant fungicide designed for oomycete pressure—notably downy mildew and late blight—in high-value vegetables and specialty crops. The stack combines Metalaxyl-M (FRAC 4) for systemic, translocated activity against oomycetes with Chlorothalonil (FRAC M05) for a broad, contact barrier that defends multiple infection points. In humid, rain-disrupted production where disease cycles re-ignite after every storm, this dual-pathway design helps stabilize outcomes by pairing curative reach with preventive coverage, supporting cleaner canopies across cucurbits, tomatoes, peppers, and watermelons—always within the scope of your registered product label.

Engineered as a suspension concentrate (SC), the formulation focuses on low settling and fast re-suspension to keep preparation consistent from the first tote to the last pallet. Process controls and range-based quality windows govern appearance, pH, viscosity, suspensibility, fineness/screening, foam tendency, and validated cold/heat storage performance. Each lot is released with a COA, supported by SDS/TDS and retention samples for traceability. For go-to-market readiness, we offer multilingual labeling, batch/QR traceability, and private-label options aligned to regulated markets.

Active Ingredients & FRAC Mechanisms — Metalaxyl-M (FRAC 4) + Chlorothalonil (FRAC M05)

Metalaxyl-M (a.k.a. mefenoxam) — FRAC 4 Phenylamide with Systemic Oomycete Reach

Metalaxyl-M provides systemic and translaminar movement, targeting oomycetes (e.g., downy mildew/late blight complexes) at early infection stages. Its value in programs is curative reach + inside-leaf protection, complementing protectant partners when disease cycles re-ignite after rainfall or irrigation. Boundaries: phenylamides face known resistance risks in certain geographies and crops; stewardship requires limited sequential exposure and rotation with non-4 partners per local registrations.

Chlorothalonil — FRAC M05 Multi-Site Protectant Barrier

Chlorothalonil acts on multiple enzymatic sites at the pathogen surface, forming a broad contact shield that protects new tissue and reduces spore germination. Multi-site action confers low resistance risk and stabilizes performance across variable inoculum loads, canopy densities, and spray intervals. Its role here is preventive coverage and durability insurance around the systemic partner.

Complementarity & Program Logic — Curative + Preventive, Inside + Outside

The FRAC 4 + M05 stack pairs inside-out protection (systemic Metalaxyl-M) with an outside-in shield (multi-site Chlorothalonil). Practically, this helps:

- Broaden spectrum against oomycete-driven outbreaks while buffering mixed complexes on leaves and stems.

- Stabilize intervals in humid, rain-disrupted cycles, where protectant film + systemic reach reduce breakthrough.

- Support rotation architecture, letting you alternate away from FRAC 4 while maintaining protectant cover.

Resistance Stewardship — How to Keep FRAC 4 Effective

- Rotate MOAs: Build seasonal or stage-based blocks with non-FRAC-4 partners; avoid phenylamide back-to-back use beyond label allowances.

- Keep multi-site cover: Maintain an M-group protectant backbone to reduce selection pressure.

- Integrate IPM: Canopy airflow, irrigation discipline, sanitation, and harvest hygiene reduce inoculum and spray stress.

- Monitor & document: Track disease pressure and outcomes; adjust block design if reduced sensitivity is suspected.

Mechanism and positioning only—no field rates, tank mixes, or stepwise directions. Use conditions must follow the registered product label and local regulations; supply is restricted to licensed buyers.

Target Diseases & Crop Fit — Oomycete Programs for Vegetables & Specialty Crops (Label-Dependent)

Oomycete Focus — Downy Mildew, Late Blight, Phytophthora-Type Complexes

Position the FRAC 4 + M05 stack for downy mildews (e.g., Pseudoperonospora, Peronospora) and late blight-type pressures (Phytophthora/related oomycetes) where systemic reach plus a multi-site barrier improves canopy protection in humid, rain-disrupted cycles. Use strictly within the registered label for crop/site and timing.

Crop Examples — Cucurbits, Tomato, Pepper, Watermelon (Check Local Label)

- Cucurbits (melon, cucumber, squash): High-value canopies with prolonged leaf wetness; protectant film plus systemic activity helps limit breakthrough after rainfall events.

- Tomato & Pepper: Integrate as a rotation block against oomycete-driven outbreaks; maintain label-aligned intervals and alternate with non-4 partners.

- Watermelon & Specialty Crops: Use where registered to buffer rapid disease cycling during warm, humid periods; coordinate with irrigation discipline and pruning/airflow practices.

Program Placement — Preventive to Early-Curative Windows (Principle-Level)

Deploy as a preventive/early-curative block, leveraging Metalaxyl-M for inside-leaf protection and Chlorothalonil for outside-in shielding. Confirm spectrum fit via scouting; if mixed pathogen complexes extend beyond oomycetes, incorporate non-FRAC-4 partners and IPM to maintain durability.

Boundary Conditions — Scope, Exclusions, and Stewardship

This formulation is not a universal fungicide for all pathogens. Do not extrapolate to unregistered crops/sites or non-oomycete targets. Stewardship requires rotations away from FRAC 4, continued M-group protectant coverage, and non-chemical practices (canopy airflow, sanitation, harvest hygiene) to reduce selection pressure over time.

Non-operational guidance only—no field rates, no tank mixes, no stepwise directions. All use must follow the registered label and local regulations; supply limited to licensed buyers.

Formulation & Quality Window — 37.5 g/L + 500 g/L Suspension Concentrate (SC)

SC Rationale — Low-Settling, Fast Re-Suspension, Audit-Friendly

The formulation is engineered as a low-settling SC to keep preparation consistent across long supply runs. A shear-resilient rheology supports fast re-suspension after storage, while a low-odor profile and clean appearance reduce handling friction in hygiene-sensitive facilities and export audits.

Process & Consistency Controls — Principle-Level, Non-Operational

- Technical material qualification: Incoming Metalaxyl-M (FRAC 4) and Chlorothalonil (FRAC M05) verified for identity/purity before batching.

- Wet-milling & stabilization: Controlled dispersion and PSD governance (D50/D90, range-based) for uniform foliar coverage without disclosing proprietary ratios.

- In-process QC: Appearance, pH, viscosity, suspensibility, and fineness/screening monitored at critical control points to secure batch-to-batch reproducibility.

- Release governance: Lots cleared only after documentation of QC checkpoints and stability outcomes in the batch dossier.

Quality Window — Range-Based Specifications (No Field Directions)

- Appearance: Uniform, off-white to light-colored aqueous suspension; no caking under gentle agitation.

- pH (range): Maintained within a validated window supporting SC stability and component compatibility.

- Viscosity / Rheology: Pumpable, shear-stable profile for consistent preparation and transfer.

- Suspensibility: Meets internal release criteria to mitigate nozzle settlement risk.

- Fineness / Screening: Pass per internal sieve benchmarks; smooth handling through standard strainers.

- Foam tendency: Controlled to streamline tank preparation (operational use is label-governed).

Stability & Shelf Life — Verified, Label-Governed

Validated cold/heat storage protocols are applied per lot; only pass-status batches are released. Shelf life is supported under sealed, cool, dry, ventilated storage as stated on the registered label. Retention samples are archived for the labeled duration to enable traceability and investigative support.

Traceability & Documentation — COA, SDS, TDS, Label Elements

Every lot ships with a Certificate of Analysis and synchronized SDS/TDS; label elements are aligned to destination regulations and artwork. Changes to raw materials or packaging follow a documented change-control workflow; production and palletization photo packs are available for intake QA upon request.

This section is non-operational and does not include field rates, tank mixes, or stepwise instructions. All handling and use must follow the registered product label and applicable local regulations.

Program Fit & Resistance Management — Rotation Blocks for Oomycete Seasons

Program Architecture — Preventive to Early-Curative Placement

Position the formulation as a preventive/early-curative block in humid, rain-disrupted cycles where downy mildew/late blight pressure is recurrent. Deploy within labeled crop/site windows, using scouting to confirm oomycete dominance before advancing the block.

Rotation Rules — FRAC 4 + M05 with Non-4 Partners

- Alternate modes of action: Build seasonal or phenology-based rotations with non-FRAC-4 partners to diversify selection pressure.

- Limit sequential FRAC 4 exposure: Adhere to label limits on consecutive applications; avoid back-to-back phenylamide use.

- Maintain protectant coverage: Keep an M-group backbone in the stack for durability and interval stability.

IPM Integration — Lower Inoculum, Raise Consistency

Combine chemistry with canopy airflow, irrigation discipline, sanitation, and harvest hygiene. Align spray intervals with weather re-wetting patterns to protect new growth while minimizing unnecessary passes (all timing is label-governed).

Safety, Storage & Compliance — GHS Alignment, Chain-of-Custody Discipline

GHS & Worker Protection

Mirror hazard/precautionary statements, signal words, and pictograms across label and SDS in destination languages. Train staff on first-aid statements and site entry policies. Worker PPE and handling practices are label-directed.

Storage & Transport

Store sealed in original containers under cool, dry, ventilated conditions; segregate from food/feed and incompatible materials. Provide SDS routing sheets, pallet maps, and emergency contacts with shipments; maintain spill kits and incident logs per facility SOP.

Regulatory Scope

Supply to licensed buyers only. Use is confined to registered crop/site scope and local legal requirements. Metalaxyl-M stewardship expectations and any regional chlorothalonil constraints must be reviewed during pre-order compliance checks.

Packaging & OEM — Multilingual Artwork, Traceability, Route-Ready Pallets

Pack Options & Materials

Retail/professional bottles (100 mL–1 L) and program/bulk cans (5–20 L) in HDPE/PET with tamper-evident closures. Outer cartons are drop-tested; pallet patterns tuned for 20GP/40HQ lanes with corner guards and wrap standards.

Artwork, Compliance & Security

Multilingual labels (EN/ES/FR/AR/RU, others on request) with batch IDs, QR traceability, and optional anti-counterfeit (hologram/serialization). Align label elements (claims, statements, barcodes) with destination regulations; keep manufacturer and emergency contacts synchronized across all artifacts.

OEM Workflow

- Scope & compliance mapping → markets, crops/sites, languages.

- Artwork lock → legal phrasing, icons, barcodes.

- Pilot & release → pre-production proofs; lot release with COA/SDS/TDS.

- Logistics kit → pallet map, packing list, SDS routing, shipment photo pack.

Evidence & Assurance — Stability, Batch Control & NDA Summaries

Stability & Quality Evidence

Validated cold/heat storage protocols applied per lot; release contingent on appearance, pH, viscosity, suspensibility, fineness/screening meeting internal windows. Shelf life supported under labeled storage conditions.

Batch Release & Traceability

COA per lot, synchronized SDS/TDS, and retention samples archived for the labeled duration. All raw-material/packaging changes governed by documented change control; production and palletization photo packs available for intake QA.

Supporting Documentation

Third-party or independent summary reports may be provided under NDA to qualified buyers; sensitive process parameters are not disclosed.

Specs & Services At-a-Glance

| Item | Summary |

|---|---|

| Product | Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC |

| FRAC / MoA | FRAC 4 phenylamide (systemic, oomycetes) + FRAC M05 multi-site protectant |

| Disease Focus | Downy mildews, late blights, Phytophthora-type complexes (label-dependent) |

| Crops (examples) | Cucurbits, tomato, pepper, watermelon (confirm local registrations) |

| Formulation | SC — low settling, fast re-suspension, low odor |

| Quality Window | Appearance/pH/viscosity/suspensibility/fineness within release ranges; cold/heat: pass |

| Documentation | COA, SDS, TDS, label elements; registration dossier on request |

| OEM & Packaging | 100 mL–1 L bottles; 5–20 L cans; HDPE/PET; multilingual labels; batch/QR; anti-counterfeit |

| Logistics | Drop-tested cartons; pallet maps (20GP/40HQ); packing list + SDS routing; shipment photo pack |

| Compliance | Licensed buyers; follow the registered label and local regulations |

FAQ

Get a Quote

Share markets, crops/sites, annual volumes, pack sizes, label languages, and document needs. We’ll return an audit-ready proposal with artwork checkpoints, pallet plan, and delivery window.

Request a Compliance & OEM Pack

Receive a curated dossier: product overview, label-elements checklist, packaging options, pallet map sample, documentation index, and shipment photo pack.

Other Metalaxyl-M Formulations

Other Chlorothalonil Formulations

| Product | Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC |

| Actives (g/L) | Metalaxyl-M: 37.5 · Chlorothalonil: 500 |

| FRAC / MoA | FRAC 4 (phenylamide, systemic/oomycetes) + FRAC M05 (multi-site protectant, contact) |

| Formulation | SC — Suspension Concentrate |

| Appearance | Uniform, low-odor aqueous suspension (low settling; fast re-suspension) |

| Target Pathogens | Oomycetes: downy mildews / late blights / Phytophthora-type complexes (label-dependent) |

| Crop Scope (examples) | Cucurbits, tomato, pepper, watermelon (confirm local registration) |

| Quality Window | pH / viscosity / suspensibility / fineness within internal release ranges (range-based) |

| Stability | Cold/heat storage: Pass (validated protocol); shelf life per label under proper storage |

| Compliance Note | For licensed buyers; use strictly per the registered product label and local regulations |

| Documentation | COA, SDS, TDS, label elements (standard); registration dossier on request |

| Packaging (indicative) | Bottles 100 mL–1 L; cans 5–20 L; HDPE/PET with tamper-evident closures |

| Labeling / Languages | Multilingual artwork (EN/ES/FR/AR/RU; others on request); claims/legal alignment |

| Traceability & Security | Batch ID, QR traceability; optional anti-counterfeit (serialization/hologram) |

| Logistics Kit | Drop-tested cartons; pallet map (20GP/40HQ); packing list + SDS routing; shipment photo pack |

Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC (FRAC 4 + M05)

Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC is a program-ready systemic + multi-site protectant fungicide designed for oomycete pressure—notably downy mildew and late blight—in high-value vegetables and specialty crops. The stack combines Metalaxyl-M (FRAC 4) for systemic, translocated activity against oomycetes with Chlorothalonil (FRAC M05) for a broad, contact barrier that defends multiple infection points. In humid, rain-disrupted production where disease cycles re-ignite after every storm, this dual-pathway design helps stabilize outcomes by pairing curative reach with preventive coverage, supporting cleaner canopies across cucurbits, tomatoes, peppers, and watermelons—always within the scope of your registered product label.

Engineered as a suspension concentrate (SC), the formulation focuses on low settling and fast re-suspension to keep preparation consistent from the first tote to the last pallet. Process controls and range-based quality windows govern appearance, pH, viscosity, suspensibility, fineness/screening, foam tendency, and validated cold/heat storage performance. Each lot is released with a COA, supported by SDS/TDS and retention samples for traceability. For go-to-market readiness, we offer multilingual labeling, batch/QR traceability, and private-label options aligned to regulated markets.

Active Ingredients & FRAC Mechanisms — Metalaxyl-M (FRAC 4) + Chlorothalonil (FRAC M05)

Metalaxyl-M (a.k.a. mefenoxam) — FRAC 4 Phenylamide with Systemic Oomycete Reach

Metalaxyl-M provides systemic and translaminar movement, targeting oomycetes (e.g., downy mildew/late blight complexes) at early infection stages. Its value in programs is curative reach + inside-leaf protection, complementing protectant partners when disease cycles re-ignite after rainfall or irrigation. Boundaries: phenylamides face known resistance risks in certain geographies and crops; stewardship requires limited sequential exposure and rotation with non-4 partners per local registrations.

Chlorothalonil — FRAC M05 Multi-Site Protectant Barrier

Chlorothalonil acts on multiple enzymatic sites at the pathogen surface, forming a broad contact shield that protects new tissue and reduces spore germination. Multi-site action confers low resistance risk and stabilizes performance across variable inoculum loads, canopy densities, and spray intervals. Its role here is preventive coverage and durability insurance around the systemic partner.

Complementarity & Program Logic — Curative + Preventive, Inside + Outside

The FRAC 4 + M05 stack pairs inside-out protection (systemic Metalaxyl-M) with an outside-in shield (multi-site Chlorothalonil). Practically, this helps:

- Broaden spectrum against oomycete-driven outbreaks while buffering mixed complexes on leaves and stems.

- Stabilize intervals in humid, rain-disrupted cycles, where protectant film + systemic reach reduce breakthrough.

- Support rotation architecture, letting you alternate away from FRAC 4 while maintaining protectant cover.

Resistance Stewardship — How to Keep FRAC 4 Effective

- Rotate MOAs: Build seasonal or stage-based blocks with non-FRAC-4 partners; avoid phenylamide back-to-back use beyond label allowances.

- Keep multi-site cover: Maintain an M-group protectant backbone to reduce selection pressure.

- Integrate IPM: Canopy airflow, irrigation discipline, sanitation, and harvest hygiene reduce inoculum and spray stress.

- Monitor & document: Track disease pressure and outcomes; adjust block design if reduced sensitivity is suspected.

Mechanism and positioning only—no field rates, tank mixes, or stepwise directions. Use conditions must follow the registered product label and local regulations; supply is restricted to licensed buyers.

Target Diseases & Crop Fit — Oomycete Programs for Vegetables & Specialty Crops (Label-Dependent)

Oomycete Focus — Downy Mildew, Late Blight, Phytophthora-Type Complexes

Position the FRAC 4 + M05 stack for downy mildews (e.g., Pseudoperonospora, Peronospora) and late blight-type pressures (Phytophthora/related oomycetes) where systemic reach plus a multi-site barrier improves canopy protection in humid, rain-disrupted cycles. Use strictly within the registered label for crop/site and timing.

Crop Examples — Cucurbits, Tomato, Pepper, Watermelon (Check Local Label)

- Cucurbits (melon, cucumber, squash): High-value canopies with prolonged leaf wetness; protectant film plus systemic activity helps limit breakthrough after rainfall events.

- Tomato & Pepper: Integrate as a rotation block against oomycete-driven outbreaks; maintain label-aligned intervals and alternate with non-4 partners.

- Watermelon & Specialty Crops: Use where registered to buffer rapid disease cycling during warm, humid periods; coordinate with irrigation discipline and pruning/airflow practices.

Program Placement — Preventive to Early-Curative Windows (Principle-Level)

Deploy as a preventive/early-curative block, leveraging Metalaxyl-M for inside-leaf protection and Chlorothalonil for outside-in shielding. Confirm spectrum fit via scouting; if mixed pathogen complexes extend beyond oomycetes, incorporate non-FRAC-4 partners and IPM to maintain durability.

Boundary Conditions — Scope, Exclusions, and Stewardship

This formulation is not a universal fungicide for all pathogens. Do not extrapolate to unregistered crops/sites or non-oomycete targets. Stewardship requires rotations away from FRAC 4, continued M-group protectant coverage, and non-chemical practices (canopy airflow, sanitation, harvest hygiene) to reduce selection pressure over time.

Non-operational guidance only—no field rates, no tank mixes, no stepwise directions. All use must follow the registered label and local regulations; supply limited to licensed buyers.

Formulation & Quality Window — 37.5 g/L + 500 g/L Suspension Concentrate (SC)

SC Rationale — Low-Settling, Fast Re-Suspension, Audit-Friendly

The formulation is engineered as a low-settling SC to keep preparation consistent across long supply runs. A shear-resilient rheology supports fast re-suspension after storage, while a low-odor profile and clean appearance reduce handling friction in hygiene-sensitive facilities and export audits.

Process & Consistency Controls — Principle-Level, Non-Operational

- Technical material qualification: Incoming Metalaxyl-M (FRAC 4) and Chlorothalonil (FRAC M05) verified for identity/purity before batching.

- Wet-milling & stabilization: Controlled dispersion and PSD governance (D50/D90, range-based) for uniform foliar coverage without disclosing proprietary ratios.

- In-process QC: Appearance, pH, viscosity, suspensibility, and fineness/screening monitored at critical control points to secure batch-to-batch reproducibility.

- Release governance: Lots cleared only after documentation of QC checkpoints and stability outcomes in the batch dossier.

Quality Window — Range-Based Specifications (No Field Directions)

- Appearance: Uniform, off-white to light-colored aqueous suspension; no caking under gentle agitation.

- pH (range): Maintained within a validated window supporting SC stability and component compatibility.

- Viscosity / Rheology: Pumpable, shear-stable profile for consistent preparation and transfer.

- Suspensibility: Meets internal release criteria to mitigate nozzle settlement risk.

- Fineness / Screening: Pass per internal sieve benchmarks; smooth handling through standard strainers.

- Foam tendency: Controlled to streamline tank preparation (operational use is label-governed).

Stability & Shelf Life — Verified, Label-Governed

Validated cold/heat storage protocols are applied per lot; only pass-status batches are released. Shelf life is supported under sealed, cool, dry, ventilated storage as stated on the registered label. Retention samples are archived for the labeled duration to enable traceability and investigative support.

Traceability & Documentation — COA, SDS, TDS, Label Elements

Every lot ships with a Certificate of Analysis and synchronized SDS/TDS; label elements are aligned to destination regulations and artwork. Changes to raw materials or packaging follow a documented change-control workflow; production and palletization photo packs are available for intake QA upon request.

This section is non-operational and does not include field rates, tank mixes, or stepwise instructions. All handling and use must follow the registered product label and applicable local regulations.

Program Fit & Resistance Management — Rotation Blocks for Oomycete Seasons

Program Architecture — Preventive to Early-Curative Placement

Position the formulation as a preventive/early-curative block in humid, rain-disrupted cycles where downy mildew/late blight pressure is recurrent. Deploy within labeled crop/site windows, using scouting to confirm oomycete dominance before advancing the block.

Rotation Rules — FRAC 4 + M05 with Non-4 Partners

- Alternate modes of action: Build seasonal or phenology-based rotations with non-FRAC-4 partners to diversify selection pressure.

- Limit sequential FRAC 4 exposure: Adhere to label limits on consecutive applications; avoid back-to-back phenylamide use.

- Maintain protectant coverage: Keep an M-group backbone in the stack for durability and interval stability.

IPM Integration — Lower Inoculum, Raise Consistency

Combine chemistry with canopy airflow, irrigation discipline, sanitation, and harvest hygiene. Align spray intervals with weather re-wetting patterns to protect new growth while minimizing unnecessary passes (all timing is label-governed).

Safety, Storage & Compliance — GHS Alignment, Chain-of-Custody Discipline

GHS & Worker Protection

Mirror hazard/precautionary statements, signal words, and pictograms across label and SDS in destination languages. Train staff on first-aid statements and site entry policies. Worker PPE and handling practices are label-directed.

Storage & Transport

Store sealed in original containers under cool, dry, ventilated conditions; segregate from food/feed and incompatible materials. Provide SDS routing sheets, pallet maps, and emergency contacts with shipments; maintain spill kits and incident logs per facility SOP.

Regulatory Scope

Supply to licensed buyers only. Use is confined to registered crop/site scope and local legal requirements. Metalaxyl-M stewardship expectations and any regional chlorothalonil constraints must be reviewed during pre-order compliance checks.

Packaging & OEM — Multilingual Artwork, Traceability, Route-Ready Pallets

Pack Options & Materials

Retail/professional bottles (100 mL–1 L) and program/bulk cans (5–20 L) in HDPE/PET with tamper-evident closures. Outer cartons are drop-tested; pallet patterns tuned for 20GP/40HQ lanes with corner guards and wrap standards.

Artwork, Compliance & Security

Multilingual labels (EN/ES/FR/AR/RU, others on request) with batch IDs, QR traceability, and optional anti-counterfeit (hologram/serialization). Align label elements (claims, statements, barcodes) with destination regulations; keep manufacturer and emergency contacts synchronized across all artifacts.

OEM Workflow

- Scope & compliance mapping → markets, crops/sites, languages.

- Artwork lock → legal phrasing, icons, barcodes.

- Pilot & release → pre-production proofs; lot release with COA/SDS/TDS.

- Logistics kit → pallet map, packing list, SDS routing, shipment photo pack.

Evidence & Assurance — Stability, Batch Control & NDA Summaries

Stability & Quality Evidence

Validated cold/heat storage protocols applied per lot; release contingent on appearance, pH, viscosity, suspensibility, fineness/screening meeting internal windows. Shelf life supported under labeled storage conditions.

Batch Release & Traceability

COA per lot, synchronized SDS/TDS, and retention samples archived for the labeled duration. All raw-material/packaging changes governed by documented change control; production and palletization photo packs available for intake QA.

Supporting Documentation

Third-party or independent summary reports may be provided under NDA to qualified buyers; sensitive process parameters are not disclosed.

Specs & Services At-a-Glance

| Item | Summary |

|---|---|

| Product | Metalaxyl-M 37.5 g/L + Chlorothalonil 500 g/L SC |

| FRAC / MoA | FRAC 4 phenylamide (systemic, oomycetes) + FRAC M05 multi-site protectant |

| Disease Focus | Downy mildews, late blights, Phytophthora-type complexes (label-dependent) |

| Crops (examples) | Cucurbits, tomato, pepper, watermelon (confirm local registrations) |

| Formulation | SC — low settling, fast re-suspension, low odor |

| Quality Window | Appearance/pH/viscosity/suspensibility/fineness within release ranges; cold/heat: pass |

| Documentation | COA, SDS, TDS, label elements; registration dossier on request |

| OEM & Packaging | 100 mL–1 L bottles; 5–20 L cans; HDPE/PET; multilingual labels; batch/QR; anti-counterfeit |

| Logistics | Drop-tested cartons; pallet maps (20GP/40HQ); packing list + SDS routing; shipment photo pack |

| Compliance | Licensed buyers; follow the registered label and local regulations |

FAQ

Get a Quote

Share markets, crops/sites, annual volumes, pack sizes, label languages, and document needs. We’ll return an audit-ready proposal with artwork checkpoints, pallet plan, and delivery window.

Request a Compliance & OEM Pack

Receive a curated dossier: product overview, label-elements checklist, packaging options, pallet map sample, documentation index, and shipment photo pack.