Cymoxanil 6%+Thiophanate-methyl 70%WP

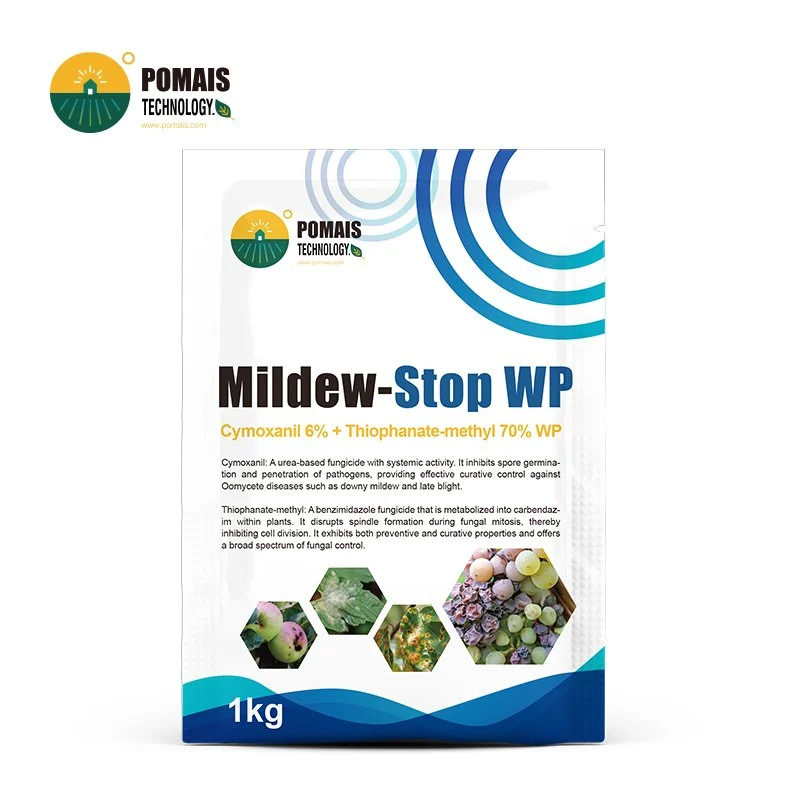

We supply Cymoxanil 6% + Thiophanate-methyl 70% WP, a dual-mode fungicide for grapes, potatoes, tomatoes and cucurbits in humid, high-pressure seasons. Cymoxanil stops early infections fast with locally systemic activity; thiophanate-methyl extends broad-spectrum protection to keep canopies clean and yields marketable. As the manufacturer, we provide OEM/private label (multilingual labels with QR/anti-counterfeit), full COA/MSDS/test data for registration, and retail/bulk packs (e.g., 500 g / 1 kg pouches; 25 kg bags) with reliable lead times by sea/air/LCL. Choose this WP when you need fast knockdown, sustained control, and consistent batch quality to reduce re-sprays across seasons.

- Designed for Professional Buyers & Bulk Orders

- This product is available for business purchase and large-scale distribution.

- We support custom packaging, labeling, and formulation to meet your market needs.

- Let’s build your brand together.

About Cymoxanil 6%+Thiophanate-methyl 70%WP

About Cymoxanil 6%+Thiophanate-methyl 70%WP

| Product | Cymoxanil 6% + Thiophanate-methyl 70% WP |

| Formulation | Wettable Powder (WP) |

| Actives & Ratio | Cymoxanil 6% (w/w) + Thiophanate-methyl 70% (w/w) |

| FRAC Codes | U27 (cymoxanil) + 1 (thiophanate-methyl) |

| Mode of Action (summary) | Early infection & sporulation suppression + mitosis inhibition; dual-site control |

| Target Crops | Grapes, potatoes, tomatoes, cucurbits, leafy vegetables, fruit trees (per local label) |

| Primary Targets | Downy mildew, late blight; anthracnose/leaf spots/powdery mildew (per local label) |

| Program Position | Preventive to early infection; tighten intervals in rainy/high-pressure periods |

| Typical Interval | 7–10 days (adjust per pressure and local label) |

| Water Volume | 200–800 L/ha depending on crop/canopy and nozzle selection |

| Tank Mix Guidance | Follow local labels; avoid incompatible alkaline/copper/oil systems; jar test if needed |

| PHI / REI | As per national label (to be confirmed for destination market) |

| Packaging – Retail | 500 g / 1 kg laminated pouches (other sizes on request) |

| Packaging – Bulk | 25 kg multi-wall bags with liner; palletized for export |

| OEM Options | Multilingual artwork (EN/AR/FR/ES/RU…), QR/anti-counterfeit, barcode/GS1, leaflet/outer box, batch/date coding |

| Documents | COA, MSDS, internal stability/suspensibility/wetting data; registration dossier support on request |

| Quality Control | Assay & impurities, pH, wetting time, suspensibility, particle-size profile, packaging integrity (per batch COA) |

| Lead Time | Typically 2–3 weeks after artwork & PO confirmation |

| Logistics | Sea/Air/LCL; consolidation with other SKUs; INCOTERMS per customer SOP |

| Certifications | ISO (factory); additional certifications available upon request |

| Notes | Final dosage, PHI/REI, and rotation limits must follow destination-country labels |

Cymoxanil 6% + Thiophanate-methyl 70% WP — How It Works & Value

This wettable powder is engineered to interrupt the disease cycle at multiple points under humid, high-pressure conditions. Cymoxanil (FRAC U27) is a cyanoacetamide-oxime with rapid, locally systemic movement (translaminar). It acts during the earliest infection steps—penetration and initial colonization—and crucially suppresses sporulation, reducing secondary inoculum and slowing epidemics of downy and late blight. Residual is intentionally short but fast; it is most effective preventively or at first visible lesions to stop outbreaks before they expand.

Thiophanate-methyl (FRAC 1) is a benzimidazole (MBC) that is metabolized in planta to carbendazim and moves acropetally via the xylem, protecting new growth. By binding β-tubulin and disrupting microtubule assembly, it halts fungal mitosis, providing mid-term protection against a broad set of ascomycete diseases (anthracnose, leaf spots, powdery mildew). In combination, the formulation delivers spectrum complementarity (oomycetes + ascomycetes) and stage complementarity (early infection + cell division), giving cleaner canopies and more stable, marketable yield across rainy periods.

Programmatically, this product fits at the preventive/early-infection window and rotates well with non-FRAC-1 partners or multi-site fungicides to maintain sensitivity. In practice, buyers see fewer emergency re-sprays, better fruit/leaf finish before harvest, and a standardizable protocol that works across tropical, subtropical, and continental climates.

Active Ingredients & Formulation (WP)

- Actives & ratio: Cymoxanil 6% + Thiophanate-methyl 70% (w/w).

- Role split: Cymoxanil = rapid, locally systemic stop on downy/late blight; Thiophanate-methyl = true systemic, mitosis inhibition for broad ascomycete control.

- What this WP delivers: fast wetting/dispersion, stable suspension, uniform leaf coverage, crop-safe at labeled rates.

- Customization: alternative strengths/ratios; WP/WG/SC options; inert system tuned to local water pH/hardness and tank-mix practice.

- Documentation: COA, MSDS, in-house stability and performance data; registration dossier support on request.

Active components & functions

| Component | Content | FRAC | Primary function | Field significance |

|---|---|---|---|---|

| Cymoxanil | 6% | U27 | Rapid, locally systemic; suppresses sporulation in oomycetes (downy/late blight) | Early knockdown; reduces secondary inoculum and outbreak speed |

| Thiophanate-methyl | 70% | 1 | Systemic (acropetal); β-tubulin binding → mitosis inhibition | Mid-term protection across anthracnose, leaf spots, powdery mildew |

Formulation engineering (what buyers get in practice)

- Wetting & dispersion: optimized wetters/dispersants for rapid wet-out and fine particle spread, supporting underside leaf coverage with correct nozzle/droplet spectrum.

- Suspension stability: CIPAC-aligned suspensibility to minimize sedimentation and nozzle blocking during long sprays.

- Flow & handling: controlled dusting and good pourability for cleaner measuring and mixing on farm.

- Crop safety window: designed for preventive/early-infection use at label rates; technical sheet includes pH range and spray-water guidance.

- Quality controls per batch: assay & impurities, pH, wetting time, suspensibility, particle-size profile, packaging integrity—reported in COA.

Customization options (OEM-ready)

- Strengths/ratios: e.g., adjusted cymoxanil content for markets prioritizing downy/late blight starts, or balanced ratios for mixed disease spectra.

- Alternative formulations:

- WG when dust control, storage robustness and fast tank breakup are prioritized;

- SC where handling convenience and reduced foaming are critical;

- Guidance provided based on your market’s spray habits and label framework.

- Inert system tuning: surfactant package calibrated to local water hardness/pH and common tank-mix partners; jar-test protocol supplied.

- Packaging: retail pouches (e.g., 500 g / 1 kg) and 25 kg bulk; multilanguage artwork, QR/anti-counterfeit, outer box/leaflet sets.

Procurement checklist (what we need to configure your SKU fast)

- Target crops/targets and any local label constraints (PHI/REI, max sprays, FRAC rotation notes).

- Expected spray water characteristics (pH/hardness) and typical adjuvants/tank-mixes.

- Preferred formulation type (WP/WG/SC) and pack sizes; languages, barcode format, and anti-counterfeit requirements.

- Registration needs: dossier format, test items required, and timeline.

Mode of Action

- Dual FRAC coverage: Cymoxanil U27 (cyanoacetamide-oxime) + Thiophanate-methyl 1 (benzimidazole/MBC) interrupt the disease cycle at different biological steps.

- Stage complementarity: Cymoxanil stops early infection & sporulation; Thiophanate-methyl halts cell division and protects new growth.

- Program fit: Best at preventive/early-infection windows; rotate away from FRAC 1 in-season; alternate with non-FRAC-1 or multi-site partners per local labels.

- Operational result: Lower epidemic speed, fewer breakthroughs in humid periods, cleaner canopies, and more stable grades.

Cymoxanil (FRAC U27)—early-step shutdown

A rapid, locally systemic active with translaminar movement. After spray deposition it quickly penetrates the cuticle and acts during the penetration/initial colonization phase of oomycetes (downy/late blight). Its signature field value is sporulation suppression—fewer spores mean reduced secondary inoculum and a slower epidemic curve. Residual is intentionally short, so performance peaks when used preventively or at first visible lesions and when intervals are tightened in rainy spells.

Thiophanate-methyl (FRAC 1)—mitosis inhibition & systemic reach

An MBC fungicide that converts to carbendazim in planta and moves acropetally via xylem, extending protection into emerging leaves and shoots. By binding β-tubulin, it disrupts microtubule assembly and halts fungal mitosis, delivering mid-term control across many ascomycete diseases (e.g., anthracnose, leaf spots, powdery mildew). Because FRAC 1 has higher resistance risk, limit seasonal uses and avoid consecutive applications.

Why the pair performs in the field

- Different targets, shared outcome: Cymoxanil reduces the source of spread (spores); Thiophanate-methyl reduces the capacity to colonize (cell division).

- Temporal coverage: Fast curative action up front + systemic follow-through on new tissue.

- Canopy integrity under humidity: Together they lower the effective reproduction rate of pathogens when moisture favors disease, translating to fewer rescue sprays.

Resistance-management guidance (practical)

- Position in preventive/early slots; respect PHI/REI and label limits on FRAC 1 totals.

- Rotate with non-FRAC-1 codes or alternate with approved multi-site partners; never rely on FRAC 1 back-to-back.

- Follow local guidance on tank-mix boundaries (e.g., alkaline/copper/oil systems); where practice requires, run a jar test before broad adoption.

Target Crops & Diseases

- Use cases: humid, high-pressure seasons where downy/late blight and mixed foliar diseases co-occur.

- Crops covered: grapes, potatoes, tomatoes, cucurbits (cucumber, melon, squash), leafy vegetables (lettuce, brassicas), fruit trees, and other field vegetables per local label.

- Primary targets: downy mildew (Peronospora, Plasmopara), late blight (Phytophthora infestans), anthracnose, leaf spots, powdery mildew (as permitted by label).

- Geography fit: tropical, subtropical, and continental climates with frequent rainfall/dew.

Crop–target map (for buyer briefing; local labels prevail)

| Crop group | Core targets | Field note |

|---|---|---|

| Grapes | Downy mildew; powdery mildew (label-dependent) | Early-season protection + rainy spells; canopy integrity before bunch closure |

| Potatoes/Tomatoes | Late blight; early leaf spots (label-dependent) | Start at first risk; tighten intervals in outbreaks |

| Cucurbits | Downy mildew; anthracnose/leaf spots | Ensure underside leaf coverage; high humidity response |

| Leafy veg/Brassicas | Downy mildew; leaf spots (where approved) | Rotation-friendly in intensive programs |

| Fruit trees/Other veg | Anthracnose/leaf spots (label-dependent) | Position near wet/humid periods; observe PHI/REI |

Application & Dosage

- Program position: preventive to early-infection; tighten intervals during rainy spells or high disease pressure.

- Intervals: typically 7–10 days under pressure; extend in stable, low-risk weather (per label).

- Coverage: ensure canopy penetration and leaf-underside wetting; maintain adequate water volume and appropriate droplet spectrum.

- Tank mixing: follow local labels; avoid incompatible alkaline/copper/oil systems; conduct jar tests where practice requires.

- Resistance limits: do not apply FRAC 1 consecutively; cap seasonal FRAC-1 uses per local guidance; rotate with non-FRAC-1 or multi-site partners.

- Regulatory: always respect PHI/REI and national label constraints.

Program framework (indicative—final rates per local label)

| Crop | Target | Timing | Interval | Water volume | Notes |

|---|---|---|---|---|---|

| Grapes | Downy mildew | Pre-bloom → bunch closure; first symptoms in rainy spells | 7–10 days | 400–800 L/ha | Focus on leaf underside; maintain spray speed/pressure |

| Potatoes | Late blight | Canopy expansion; first risk alert | 7–10 days | 200–500 L/ha | Tighten post-rain; avoid back-to-back FRAC 1 |

| Tomatoes | Late blight/leaf spots* | Early canopy → fruit set | 7–10 days | 300–600 L/ha | Calibrate nozzles; observe PHI |

| Cucurbits | Downy mildew | First risk to harvest | 7–10 days | 300–600 L/ha | Improve coverage with correct droplet size |

*Where permitted by local label.

Buyer note: Typical WP use-rates vary by country and label; we will align dosage tables, PHI/REI, and rotation notes to your registration.

Why Choose This Product

- Dual-mode certainty: early infection and sporulation are stopped by cymoxanil; cell division and colonization are suppressed by thiophanate-methyl—fewer breakthroughs in wet periods.

- Canopy cleanliness → marketable yield: cleaner foliage and fruit finish before harvest, reducing downgrades.

- Rotation-friendly: plugs naturally into FRAC-guided programs; easy to standardize across multiple crops and climates.

- WP engineered for the field: fast wetting/dispersion, stable suspension, controlled dust—built for long spray days.

- Manufacturer-backed OEM: consistent batches, multilingual labels with QR/anti-counterfeit, COA/MSDS/test data, and dossier support to accelerate market entry.

- Service you can plan around: predictable lead times, consolidated shipments, and post-launch technical guidance.

Packaging & OEM Support

- Retail packs: 500 g / 1 kg laminated pouches; other sizes on request.

- Bulk: 25 kg multi-wall bags with liner; palletized for export.

- OEM options: artwork in EN/AR/FR/ES/RU (others on request), QR/anti-counterfeit, barcodes, outer box and leaflet sets, batch/date coding.

- Documentation package: COA, MSDS, in-house stability/suspensibility/wetting data; registration dossier support where required.

- Lead times & logistics: typical production lead time 2–3 weeks after artwork and PO confirmation; sea/air/LCL per your INCOTERMS; consolidation available.

- What we need to move fast: target countries, crops/targets for label alignment, preferred pack sizes, languages, and any anti-counterfeit requirements.

Export & Service Capability

- Markets & channels: Built for importers, distributors, and private-label brands across MEA, CIS, LATAM, and Southeast Asia.

- Lead times: Typical production 2–3 weeks after artwork and PO confirmation; expedited slots available in peak season subject to raw-material status.

- Logistics: Sea, air, and LCL; palletized export packing; consolidation with other SKUs on request; INCOTERMS per your SOP.

- Quality & compliance: Batch COA (assay, impurities, pH, wetting time, suspensibility, particle-size profile), MSDS, and internal stability data provided; registration dossier support where required.

- OEM enablement: Multilingual artwork (EN/AR/FR/ES/RU and others), QR/anti-counterfeit, barcode/GS1 formats, outer box and leaflet sets, batch/date coding.

- After-sales support: Technical positioning for preventive/early windows, rotation templates by crop/pressure level, and field-coverage best practices.

Storage & Safety

- Storage: Keep sealed in a cool, dry, well-ventilated place away from direct sunlight and food/feed. Avoid moisture pickup; use pallets and protective liners.

- Handling & PPE: Wear chemical-resistant gloves, long sleeves, goggles/face shield, and a respirator suitable for fine powders during mixing/loading.

- Mixing: Add product to a half-filled tank with agitation; maintain agitation during spraying. Observe local label boundaries for alkaline, copper, or oil systems; run a jar test if practice requires.

- First aid (general guidance—follow local labels):

- Skin contact: wash with soap and water.

- Eye contact: rinse with clean water for 15 minutes; seek medical advice.

- Ingestion: do not induce vomiting; get medical attention immediately with product label/MSDS.

- Re-entry/PHI: Respect national label requirements for REI/PHI; align program design accordingly.

- Container management: Triple-rinse where applicable; dispose per local regulation. Prevent contamination of waterways.

FAQ

Q: Can I tank-mix it with copper or oil-based products?

A: Follow local labels. Where permitted, avoid high-alkaline systems and perform a jar test before broad adoption.

Q: What interval should I use in rainy, high-pressure periods?

A: Position at preventive/early infection with 7–10-day intervals; tighten when disease pressure or rainfall increases, per label.

Q: Does it move into new growth?

A: Thiophanate-methyl moves acropetally to protect emerging tissue; cymoxanil provides fast early-step shutdown.

Q: How does it fit resistance management?

A: Do not apply FRAC 1 consecutively; rotate with non-FRAC-1 or multi-site partners and cap seasonal FRAC-1 uses per national guidance.

Q: What crops and targets are best suited?

A: Grapes, potatoes, tomatoes, cucurbits, leafy vegetables, and fruit trees against downy/late blight and label-listed leaf diseases; confirm local registrations.

Q: What documentation do you supply for registration?

A: COA, MSDS, internal stability/performance data, and dossier support as required by the destination authority.

Q: What packaging can you provide for retail and bulk?

A: 500 g / 1 kg laminated pouches for retail; 25 kg multi-wall bags with liner for bulk; custom sizes and languages available.

Q: Typical lead time and shipping options?

A: 2–3 weeks production after artwork/PO, shipped by sea/air/LCL under your preferred INCOTERMS; consolidation available.

Ready to standardize a reliable WP for downy/late blight and mixed foliar programs? Share your target countries, crops/targets, pack sizes, and label languages, and we will return a configured OEM plan, documents list, and delivery schedule for your market.

| Product | Cymoxanil 6% + Thiophanate-methyl 70% WP |

| Formulation | Wettable Powder (WP) |

| Actives & Ratio | Cymoxanil 6% (w/w) + Thiophanate-methyl 70% (w/w) |

| FRAC Codes | U27 (cymoxanil) + 1 (thiophanate-methyl) |

| Mode of Action (summary) | Early infection & sporulation suppression + mitosis inhibition; dual-site control |

| Target Crops | Grapes, potatoes, tomatoes, cucurbits, leafy vegetables, fruit trees (per local label) |

| Primary Targets | Downy mildew, late blight; anthracnose/leaf spots/powdery mildew (per local label) |

| Program Position | Preventive to early infection; tighten intervals in rainy/high-pressure periods |

| Typical Interval | 7–10 days (adjust per pressure and local label) |

| Water Volume | 200–800 L/ha depending on crop/canopy and nozzle selection |

| Tank Mix Guidance | Follow local labels; avoid incompatible alkaline/copper/oil systems; jar test if needed |

| PHI / REI | As per national label (to be confirmed for destination market) |

| Packaging – Retail | 500 g / 1 kg laminated pouches (other sizes on request) |

| Packaging – Bulk | 25 kg multi-wall bags with liner; palletized for export |

| OEM Options | Multilingual artwork (EN/AR/FR/ES/RU…), QR/anti-counterfeit, barcode/GS1, leaflet/outer box, batch/date coding |

| Documents | COA, MSDS, internal stability/suspensibility/wetting data; registration dossier support on request |

| Quality Control | Assay & impurities, pH, wetting time, suspensibility, particle-size profile, packaging integrity (per batch COA) |

| Lead Time | Typically 2–3 weeks after artwork & PO confirmation |

| Logistics | Sea/Air/LCL; consolidation with other SKUs; INCOTERMS per customer SOP |

| Certifications | ISO (factory); additional certifications available upon request |

| Notes | Final dosage, PHI/REI, and rotation limits must follow destination-country labels |

Cymoxanil 6% + Thiophanate-methyl 70% WP — How It Works & Value

This wettable powder is engineered to interrupt the disease cycle at multiple points under humid, high-pressure conditions. Cymoxanil (FRAC U27) is a cyanoacetamide-oxime with rapid, locally systemic movement (translaminar). It acts during the earliest infection steps—penetration and initial colonization—and crucially suppresses sporulation, reducing secondary inoculum and slowing epidemics of downy and late blight. Residual is intentionally short but fast; it is most effective preventively or at first visible lesions to stop outbreaks before they expand.

Thiophanate-methyl (FRAC 1) is a benzimidazole (MBC) that is metabolized in planta to carbendazim and moves acropetally via the xylem, protecting new growth. By binding β-tubulin and disrupting microtubule assembly, it halts fungal mitosis, providing mid-term protection against a broad set of ascomycete diseases (anthracnose, leaf spots, powdery mildew). In combination, the formulation delivers spectrum complementarity (oomycetes + ascomycetes) and stage complementarity (early infection + cell division), giving cleaner canopies and more stable, marketable yield across rainy periods.

Programmatically, this product fits at the preventive/early-infection window and rotates well with non-FRAC-1 partners or multi-site fungicides to maintain sensitivity. In practice, buyers see fewer emergency re-sprays, better fruit/leaf finish before harvest, and a standardizable protocol that works across tropical, subtropical, and continental climates.

Active Ingredients & Formulation (WP)

- Actives & ratio: Cymoxanil 6% + Thiophanate-methyl 70% (w/w).

- Role split: Cymoxanil = rapid, locally systemic stop on downy/late blight; Thiophanate-methyl = true systemic, mitosis inhibition for broad ascomycete control.

- What this WP delivers: fast wetting/dispersion, stable suspension, uniform leaf coverage, crop-safe at labeled rates.

- Customization: alternative strengths/ratios; WP/WG/SC options; inert system tuned to local water pH/hardness and tank-mix practice.

- Documentation: COA, MSDS, in-house stability and performance data; registration dossier support on request.

Active components & functions

| Component | Content | FRAC | Primary function | Field significance |

|---|---|---|---|---|

| Cymoxanil | 6% | U27 | Rapid, locally systemic; suppresses sporulation in oomycetes (downy/late blight) | Early knockdown; reduces secondary inoculum and outbreak speed |

| Thiophanate-methyl | 70% | 1 | Systemic (acropetal); β-tubulin binding → mitosis inhibition | Mid-term protection across anthracnose, leaf spots, powdery mildew |

Formulation engineering (what buyers get in practice)

- Wetting & dispersion: optimized wetters/dispersants for rapid wet-out and fine particle spread, supporting underside leaf coverage with correct nozzle/droplet spectrum.

- Suspension stability: CIPAC-aligned suspensibility to minimize sedimentation and nozzle blocking during long sprays.

- Flow & handling: controlled dusting and good pourability for cleaner measuring and mixing on farm.

- Crop safety window: designed for preventive/early-infection use at label rates; technical sheet includes pH range and spray-water guidance.

- Quality controls per batch: assay & impurities, pH, wetting time, suspensibility, particle-size profile, packaging integrity—reported in COA.

Customization options (OEM-ready)

- Strengths/ratios: e.g., adjusted cymoxanil content for markets prioritizing downy/late blight starts, or balanced ratios for mixed disease spectra.

- Alternative formulations:

- WG when dust control, storage robustness and fast tank breakup are prioritized;

- SC where handling convenience and reduced foaming are critical;

- Guidance provided based on your market’s spray habits and label framework.

- Inert system tuning: surfactant package calibrated to local water hardness/pH and common tank-mix partners; jar-test protocol supplied.

- Packaging: retail pouches (e.g., 500 g / 1 kg) and 25 kg bulk; multilanguage artwork, QR/anti-counterfeit, outer box/leaflet sets.

Procurement checklist (what we need to configure your SKU fast)

- Target crops/targets and any local label constraints (PHI/REI, max sprays, FRAC rotation notes).

- Expected spray water characteristics (pH/hardness) and typical adjuvants/tank-mixes.

- Preferred formulation type (WP/WG/SC) and pack sizes; languages, barcode format, and anti-counterfeit requirements.

- Registration needs: dossier format, test items required, and timeline.

Mode of Action

- Dual FRAC coverage: Cymoxanil U27 (cyanoacetamide-oxime) + Thiophanate-methyl 1 (benzimidazole/MBC) interrupt the disease cycle at different biological steps.

- Stage complementarity: Cymoxanil stops early infection & sporulation; Thiophanate-methyl halts cell division and protects new growth.

- Program fit: Best at preventive/early-infection windows; rotate away from FRAC 1 in-season; alternate with non-FRAC-1 or multi-site partners per local labels.

- Operational result: Lower epidemic speed, fewer breakthroughs in humid periods, cleaner canopies, and more stable grades.

Cymoxanil (FRAC U27)—early-step shutdown

A rapid, locally systemic active with translaminar movement. After spray deposition it quickly penetrates the cuticle and acts during the penetration/initial colonization phase of oomycetes (downy/late blight). Its signature field value is sporulation suppression—fewer spores mean reduced secondary inoculum and a slower epidemic curve. Residual is intentionally short, so performance peaks when used preventively or at first visible lesions and when intervals are tightened in rainy spells.

Thiophanate-methyl (FRAC 1)—mitosis inhibition & systemic reach

An MBC fungicide that converts to carbendazim in planta and moves acropetally via xylem, extending protection into emerging leaves and shoots. By binding β-tubulin, it disrupts microtubule assembly and halts fungal mitosis, delivering mid-term control across many ascomycete diseases (e.g., anthracnose, leaf spots, powdery mildew). Because FRAC 1 has higher resistance risk, limit seasonal uses and avoid consecutive applications.

Why the pair performs in the field

- Different targets, shared outcome: Cymoxanil reduces the source of spread (spores); Thiophanate-methyl reduces the capacity to colonize (cell division).

- Temporal coverage: Fast curative action up front + systemic follow-through on new tissue.

- Canopy integrity under humidity: Together they lower the effective reproduction rate of pathogens when moisture favors disease, translating to fewer rescue sprays.

Resistance-management guidance (practical)

- Position in preventive/early slots; respect PHI/REI and label limits on FRAC 1 totals.

- Rotate with non-FRAC-1 codes or alternate with approved multi-site partners; never rely on FRAC 1 back-to-back.

- Follow local guidance on tank-mix boundaries (e.g., alkaline/copper/oil systems); where practice requires, run a jar test before broad adoption.

Target Crops & Diseases

- Use cases: humid, high-pressure seasons where downy/late blight and mixed foliar diseases co-occur.

- Crops covered: grapes, potatoes, tomatoes, cucurbits (cucumber, melon, squash), leafy vegetables (lettuce, brassicas), fruit trees, and other field vegetables per local label.

- Primary targets: downy mildew (Peronospora, Plasmopara), late blight (Phytophthora infestans), anthracnose, leaf spots, powdery mildew (as permitted by label).

- Geography fit: tropical, subtropical, and continental climates with frequent rainfall/dew.

Crop–target map (for buyer briefing; local labels prevail)

| Crop group | Core targets | Field note |

|---|---|---|

| Grapes | Downy mildew; powdery mildew (label-dependent) | Early-season protection + rainy spells; canopy integrity before bunch closure |

| Potatoes/Tomatoes | Late blight; early leaf spots (label-dependent) | Start at first risk; tighten intervals in outbreaks |

| Cucurbits | Downy mildew; anthracnose/leaf spots | Ensure underside leaf coverage; high humidity response |

| Leafy veg/Brassicas | Downy mildew; leaf spots (where approved) | Rotation-friendly in intensive programs |

| Fruit trees/Other veg | Anthracnose/leaf spots (label-dependent) | Position near wet/humid periods; observe PHI/REI |

Application & Dosage

- Program position: preventive to early-infection; tighten intervals during rainy spells or high disease pressure.

- Intervals: typically 7–10 days under pressure; extend in stable, low-risk weather (per label).

- Coverage: ensure canopy penetration and leaf-underside wetting; maintain adequate water volume and appropriate droplet spectrum.

- Tank mixing: follow local labels; avoid incompatible alkaline/copper/oil systems; conduct jar tests where practice requires.

- Resistance limits: do not apply FRAC 1 consecutively; cap seasonal FRAC-1 uses per local guidance; rotate with non-FRAC-1 or multi-site partners.

- Regulatory: always respect PHI/REI and national label constraints.

Program framework (indicative—final rates per local label)

| Crop | Target | Timing | Interval | Water volume | Notes |

|---|---|---|---|---|---|

| Grapes | Downy mildew | Pre-bloom → bunch closure; first symptoms in rainy spells | 7–10 days | 400–800 L/ha | Focus on leaf underside; maintain spray speed/pressure |

| Potatoes | Late blight | Canopy expansion; first risk alert | 7–10 days | 200–500 L/ha | Tighten post-rain; avoid back-to-back FRAC 1 |

| Tomatoes | Late blight/leaf spots* | Early canopy → fruit set | 7–10 days | 300–600 L/ha | Calibrate nozzles; observe PHI |

| Cucurbits | Downy mildew | First risk to harvest | 7–10 days | 300–600 L/ha | Improve coverage with correct droplet size |

*Where permitted by local label.

Buyer note: Typical WP use-rates vary by country and label; we will align dosage tables, PHI/REI, and rotation notes to your registration.

Why Choose This Product

- Dual-mode certainty: early infection and sporulation are stopped by cymoxanil; cell division and colonization are suppressed by thiophanate-methyl—fewer breakthroughs in wet periods.

- Canopy cleanliness → marketable yield: cleaner foliage and fruit finish before harvest, reducing downgrades.

- Rotation-friendly: plugs naturally into FRAC-guided programs; easy to standardize across multiple crops and climates.

- WP engineered for the field: fast wetting/dispersion, stable suspension, controlled dust—built for long spray days.

- Manufacturer-backed OEM: consistent batches, multilingual labels with QR/anti-counterfeit, COA/MSDS/test data, and dossier support to accelerate market entry.

- Service you can plan around: predictable lead times, consolidated shipments, and post-launch technical guidance.

Packaging & OEM Support

- Retail packs: 500 g / 1 kg laminated pouches; other sizes on request.

- Bulk: 25 kg multi-wall bags with liner; palletized for export.

- OEM options: artwork in EN/AR/FR/ES/RU (others on request), QR/anti-counterfeit, barcodes, outer box and leaflet sets, batch/date coding.

- Documentation package: COA, MSDS, in-house stability/suspensibility/wetting data; registration dossier support where required.

- Lead times & logistics: typical production lead time 2–3 weeks after artwork and PO confirmation; sea/air/LCL per your INCOTERMS; consolidation available.

- What we need to move fast: target countries, crops/targets for label alignment, preferred pack sizes, languages, and any anti-counterfeit requirements.

Export & Service Capability

- Markets & channels: Built for importers, distributors, and private-label brands across MEA, CIS, LATAM, and Southeast Asia.

- Lead times: Typical production 2–3 weeks after artwork and PO confirmation; expedited slots available in peak season subject to raw-material status.

- Logistics: Sea, air, and LCL; palletized export packing; consolidation with other SKUs on request; INCOTERMS per your SOP.

- Quality & compliance: Batch COA (assay, impurities, pH, wetting time, suspensibility, particle-size profile), MSDS, and internal stability data provided; registration dossier support where required.

- OEM enablement: Multilingual artwork (EN/AR/FR/ES/RU and others), QR/anti-counterfeit, barcode/GS1 formats, outer box and leaflet sets, batch/date coding.

- After-sales support: Technical positioning for preventive/early windows, rotation templates by crop/pressure level, and field-coverage best practices.

Storage & Safety

- Storage: Keep sealed in a cool, dry, well-ventilated place away from direct sunlight and food/feed. Avoid moisture pickup; use pallets and protective liners.

- Handling & PPE: Wear chemical-resistant gloves, long sleeves, goggles/face shield, and a respirator suitable for fine powders during mixing/loading.

- Mixing: Add product to a half-filled tank with agitation; maintain agitation during spraying. Observe local label boundaries for alkaline, copper, or oil systems; run a jar test if practice requires.

- First aid (general guidance—follow local labels):

- Skin contact: wash with soap and water.

- Eye contact: rinse with clean water for 15 minutes; seek medical advice.

- Ingestion: do not induce vomiting; get medical attention immediately with product label/MSDS.

- Re-entry/PHI: Respect national label requirements for REI/PHI; align program design accordingly.

- Container management: Triple-rinse where applicable; dispose per local regulation. Prevent contamination of waterways.

FAQ

Q: Can I tank-mix it with copper or oil-based products?

A: Follow local labels. Where permitted, avoid high-alkaline systems and perform a jar test before broad adoption.

Q: What interval should I use in rainy, high-pressure periods?

A: Position at preventive/early infection with 7–10-day intervals; tighten when disease pressure or rainfall increases, per label.

Q: Does it move into new growth?

A: Thiophanate-methyl moves acropetally to protect emerging tissue; cymoxanil provides fast early-step shutdown.

Q: How does it fit resistance management?

A: Do not apply FRAC 1 consecutively; rotate with non-FRAC-1 or multi-site partners and cap seasonal FRAC-1 uses per national guidance.

Q: What crops and targets are best suited?

A: Grapes, potatoes, tomatoes, cucurbits, leafy vegetables, and fruit trees against downy/late blight and label-listed leaf diseases; confirm local registrations.

Q: What documentation do you supply for registration?

A: COA, MSDS, internal stability/performance data, and dossier support as required by the destination authority.

Q: What packaging can you provide for retail and bulk?

A: 500 g / 1 kg laminated pouches for retail; 25 kg multi-wall bags with liner for bulk; custom sizes and languages available.

Q: Typical lead time and shipping options?

A: 2–3 weeks production after artwork/PO, shipped by sea/air/LCL under your preferred INCOTERMS; consolidation available.

Ready to standardize a reliable WP for downy/late blight and mixed foliar programs? Share your target countries, crops/targets, pack sizes, and label languages, and we will return a configured OEM plan, documents list, and delivery schedule for your market.