Tebufenozide 24% SC – IRAC 18 IGR for Stored-Product & Urban Moth Management

You need a moth-larvae solution that protects inventory integrity without introducing odor, residue, or headline risk. Tebufenozide 24% SC delivers selective, hormone-based control of Lepidopteran larvae in stored-product and urban logistics environments—built for consistency, OEM flexibility, and compliant distribution.

-

Active Ingredient: Tebufenozide | IRAC Group: 18 (Ecdysone receptor agonist)

-

Formulation: 24% SC (Suspension Concentrate)

-

Target: Lepidopteran larvae (stored-product and urban moth species)

-

Use Focus: Food warehouses, packaging areas, textile/archive storage, urban transit hubs

-

Documentation: COA, SDS, TDS, label elements available

-

OEM/Private Label: Bottle, label, carton, pallet plan customizable

- Designed for Professional Buyers & Bulk Orders

- We support custom packaging, labeling, and formulation to meet your market needs.

- Export wholesale inquiries only.

- Please include destination country, business type (importer/distributor/registrant), and expected volume.

- Retail requests will not be processed.

About Tebufenozide 24% SC – IRAC 18 IGR for Stored-Product & Urban Moth Management

| Active Ingredient | Tebufenozide |

| CAS | 112410-23-8 |

| IRAC Group | 18 (Ecdysone receptor agonist, IGR) |

| Formulation | 24% SC (Suspension Concentrate) |

| Appearance | Uniform, low-odor aqueous suspension |

| Quality Window | pH / Viscosity / Suspensibility within validated release ranges |

| Stability | Cold/Heat storage: Pass (per validated protocol) |

| Shelf Life | Within labeled range under recommended storage |

| Use Domain | Stored-product & urban moth larvae programs |

| Not For | Public-health vectors (mosquitoes/flies/fleas), adult knockdown |

| Documents | COA, SDS, TDS, label elements; registration support on request |

| Compliance Note | For licensed buyers; always follow the product label & local regulations |

Tebufenozide 24% SC – IRAC 18 IGR for Stored-Product & Urban Moth Management

Tebufenozide 24% SC is a diacylhydrazine insect growth regulator (IGR) formulated as a suspension concentrate for professional use in stored-product and urban logistics environments. It targets Lepidopteran larval stages (moth larvae) that damage packaged foods, paperboard, textiles, and archives. The product is selective (larvae-focused), non-knockdown (not for adult quick kill), and engineered for low odor/low staining, making it fit for hygiene-sensitive facilities.

Positioning

- Use domain: Stored-product hygiene and urban moth management (warehouses, packaging areas, transit hubs, textile/archive storage).

- What it is not: Not a public-health vector adulticide; not intended for mosquitoes/flies/fleas; not a fumigant.

- Program role: A foundation larvicide within an IPM (integrated pest management) program alongside sanitation, exclusion, monitoring, and—where needed—non-Group-18 chemistries for rotation.

Compliance scope

- Supplied to licensed buyers operating under local regulations. Always follow the registered product label. Do not use outside its labeled pest/crop/site scope.

Mode of Action & Selectivity

Hormone-mimic mechanism (IRAC Group 18): Tebufenozide is an ecdysone-receptor agonist. It mimics the insect molting hormone, triggering abortive or premature molting in susceptible moth larvae. The outcome is feeding cessation followed by larval death, delivering protection without the solvent load or odor profile typical of many knockdown chemistries.

Why this matters operationally

- Selective on targets: High activity on Lepidopteran larvae; limited effect on non-target groups and adult stages, supporting hygiene programs where material compatibility and worker comfort matter.

- Residency vs. rebound: By interrupting development, programs experience fewer “hidden” survivors that later emerge as adults, reducing re-infestation pressure across batches.

- Program stability: Non-repellent profile and low odor help maintain standard operating conditions in handling/packing areas.

Resistance management (principle-level)

- Rotate with non-Group-18 actives in season-long or batch-based programs.

- Combine with non-chemical controls (sanitation, sealing/gapping fixes, temperature/humidity management, monitoring traps) to reduce selection pressure.

- Maintain label-directed intervals and application windows; avoid continuous, single-MOA reliance.

Stewardship note: Risk = Hazard × Exposure. Product stewardship, label adherence, and site-appropriate PPE are mandatory.

Targets & Use Cases — Stored-Product & Urban Logistics

Target profile (Lepidopteran larvae focus)

- Stored-product moths: Indian meal moth, Mediterranean flour moth, almond moth—larvae feeding on grains, nuts, flour mixes, confectionery.

- Clothes & museum moths: Common/Case-bearing clothes moth—larvae damaging natural fibers, felt, paperboard liners, archival materials.

- Warehouse/packaging moths: Species colonizing corrugated voids, paper dust, food residues, and mixed-material packaging streams.

Where it fits best

- Food warehouses & DCs: Prevent larval feeding on packaged goods and bulk ingredients; protect SKU integrity and complaint rates across turnover cycles.

- Packaging & kitting areas: Safeguard semi-finished goods (cartons, inserts, wraps) where paper dust and food residues encourage larval hotspots.

- Urban transit hubs & 3PL sites: Maintain hygiene baselines in high-throughput, mixed-commodity environments with frequent pallet moves.

- Textile/archive storage & specialty collections: Help preserve fibers, textiles, and archival papers under IPM protocols that favor low-odor, low-stain chemistries.

Use-case matrix (principle-level guidance)

- Food warehouse → Stored-product moth larvae → Larvae-focused intervention alongside sanitation, sealing, and monitoring; aim to break development cycles between batches.

- Packaging floor → Packaging-associated moth larvae → Support preventive hygiene SOPs; compatible with routine cleaning and non-repellent monitoring.

- Urban 3PL hub → Mixed-origin infestations → Stabilize baseline pressure where frequent inbound loads raise re-introduction risk; pair with inspection and quarantine zones.

- Textile/archive store → Clothes/museum moth larvae → Complement environmental controls (temperature, humidity, exclusion); prioritize material compatibility and low odor.

Program design cues (non-operational)

- IPM anchor, not a knockdown: Position as the larval-stage pillar; pair with adult monitoring and exclusion to prevent recolonization.

- Rotation logic: Alternate with non-IRAC 18 actives in season-long or batch-based plans to reduce selection pressure.

- Hygiene synergy: Effectiveness scales with sanitation (debris removal, spillage control), structural fixes (gaps/seals), and environmental management (temperature/humidity).

- Material considerations: Low odor/low staining profile supports use near packaging lines, cartons, textiles, and archives where residues are reputationally sensitive.

Boundary note: This product is not intended for public-health vector control (mosquitoes/flies/fleas) or rapid adult knockdown. It is optimized for larval interruption in Lepidopteran species within stored-product and urban logistics contexts.

Formulation & Quality Window — 24% SC (Suspension Concentrate)

Built for professional programs where batch-to-batch consistency and material compatibility matter.

Formulation rationale

- 24% SC platform: Stable, easy-to-handle suspension designed for uniform dispersion; optimized wetting/dispersing system to support consistent performance in hygiene-sensitive facilities.

- Low-odor, low-staining profile: Supports use near cartons, textiles, archival papers, and packaging lines where residues and smell are reputation-critical.

- Process control: QA gates across technical material qualification, dispersion/homogenization, and in-process physico-chemical checks; cold/heat storage verification prior to release.

Quality window (principle-level)

- Appearance, pH, suspensibility/viscosity, and storage stability are maintained within validated release ranges.

- Retention samples kept per batch; COA issued against release criteria.

- Compatibility guidance available at program level (no mix recipes disclosed; follow the registered label).

Technical Profile (indicative fields for your COA/TDS)

| Field | Value / Range (principle-level) |

|---|---|

| Active Ingredient | Tebufenozide |

| IRAC Group | 18 (Ecdysone receptor agonist) |

| Formulation Type | 24% SC (Suspension Concentrate) |

| Appearance | Uniform, low-odor aqueous suspension |

| pH (range) | Maintained within validated release window |

| Viscosity / Rheology | Controlled for pumpability and dispersion |

| Suspensibility | Meets internal release criteria |

| Cold/Heat Storage | Pass (validated stability protocol) |

| Shelf Life | Within labeled range under recommended storage |

| Documentation | COA, SDS, TDS, label elements (upon order) |

Note: Specifications are controlled under our QA system. Exact numerical limits and test methods are provided in the product dossier to licensed buyers, and usage must follow the registered label and local regulations.

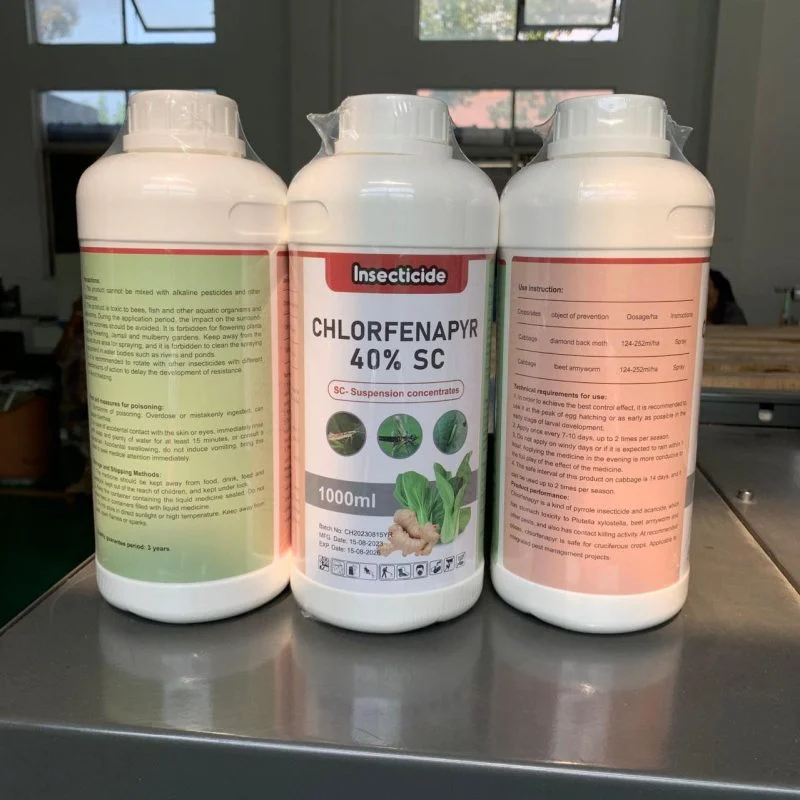

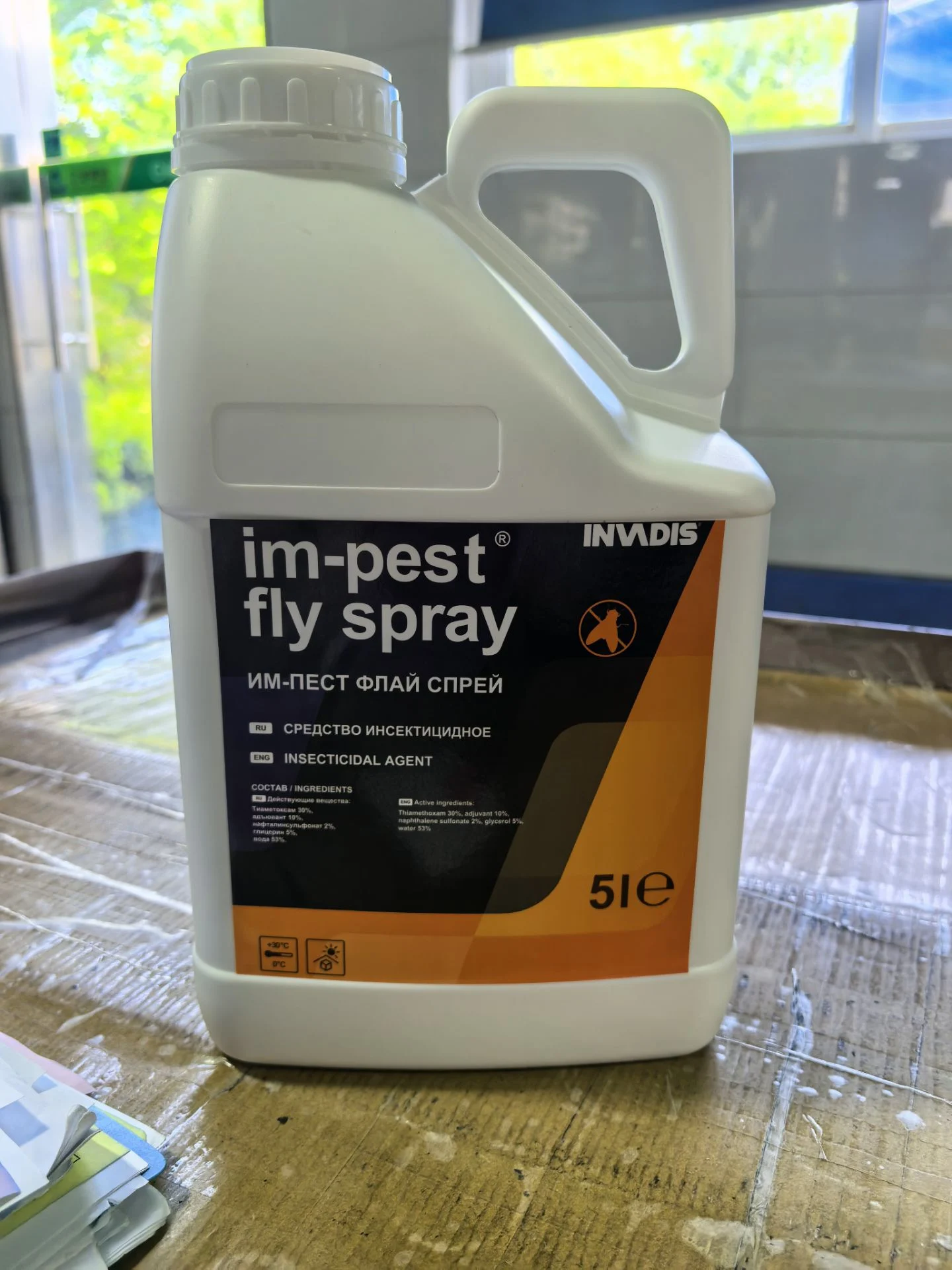

Packaging & OEM — Private Label, Multilingual, Ready for Scale

Engineered for distributors and program operators that need compliant presentation, fast turn, and market-fit customization.

Packaging architecture

- Primary containers: HDPE/PET bottles (tamper-evident caps), laminated pouches (select markets), bulk jerrycans for repack partners.

- Net content ranges: 100 mL–1 L (retail/professional); larger SKUs for B2B programs by agreement.

- Labeling: Multilingual artwork, region-specific risk phrases and pictograms, batch and QR traceability, optional anti-counterfeit features.

- Cartoning & palletization: Drop-tested outer cartons, shrink or strap options, pallet patterns tailored to lane constraints and lane cost.

- Regulatory artifacts: COA/SDS/TDS + label elements; registration support dossier on request.

Packaging Options (indicative fields)

| Bottle / Pack Type | Net Content Range | Label Languages | Units / Carton | Carton (L×W×H) & GW* | Palletization | Container Loading Notes |

|---|---|---|---|---|---|---|

| HDPE round bottle | 100–250 mL | EN/ES/FR/AR/RU | 24–48 | Range-based, per SKU | 10–12 cartons/layer | Optimize for 20GP mixed-SKU loads |

| HDPE square bottle | 500 mL–1 L | EN/ES/AR/RU | 12–24 | Range-based, per SKU | 8–10 cartons/layer | Favor block-stacking for stability |

| PET lightweight | 250–500 mL | EN/ES/FR | 24 | Range-based, per SKU | 10–12 cartons/layer | Use corner guards in warm lanes |

| Laminate pouch** | 100–250 mL | EN/ES | 50–100 | Range-based, per SKU | 12–16 cartons/layer | Secondary tray recommended |

| Jerrycan (bulk) | 5–20 L | EN (others on req.) | 2–4 | Range-based, per SKU | 6–8 per layer | Brace for inland haul vibration |

* GW=gross weight; exact dimensions/weights are finalized at artwork lock.

** Availability subject to local regulations and registration scope.

OEM / Private label workflow

- Scope & specs: Confirm markets, languages, target channels, and net contents.

- Artwork & compliance: Align label elements with local regulations; freeze barcodes, batch/QR, and safety icons.

- Pilot & release: Pre-production samples for fit/finish; sign-off with COA/SDS/TDS references.

- Production & QC: In-line inspections; batch retention and documentation.

- Logistics kit: Pallet map, MSDS routing sheets, packing list/commercial docs, and photo pack for intake QA.

Service options

- Multi-language artwork localization, regulatory phrasing harmonization, anti-counterfeit features, pallet optimization by route, and photographic QC packs for distributors’ onboarding.

System Fit & Program Design — How to Deploy Without Disruption

Role in IPM (Integrated Pest Management)

- Larval-stage pillar: Use Tebufenozide 24% SC as the development interrupter for Lepidopteran larvae.

- Not a knockdown: Pair with adult monitoring/controls where adult pressure is visible; avoid relying on a single MOA.

- Hygiene multiplier: Outcomes scale with sanitation, structural exclusion, and environmental control.

Program architecture (principle-level, non-operational)

- Baseline assessment

- Map sensitive zones: receiving, repack, kitting, long-stay storage, high-dust areas, archive stacks.

- Identify risk vectors: inbound pallets, corrugated voids, paper dust, food residues, textile clusters.

- Establish KPIs: complaint rate, trap counts (adults), visual larval finds per zone, rework/hold incidents.

- Control stack

- Larval interruption: Tebufenozide 24% SC as the core for Lepidopteran larvae in risk zones.

- Adult surveillance: Non-repellent traps and visual inspections to detect breakthrough and re-introduction.

- Physical & procedural: Deep clean, seal gaps, segregate suspect inbounds, rotate stock (FIFO/FEFO), temperature/humidity discipline.

- Rotation logic (resistance stewardship)

- Alternate Tebufenozide (IRAC 18) with non-18 chemistries in season-long or batch-based plans.

- Use mode-of-action diversity across the program year; avoid continuous single-MOA dependency.

- Document rotations in a simple matrix (zone × month × MOA) for auditability.

- Facility-type blueprints (examples)

- Food warehouses & DCs: Focus on receiving → repack → long-stay lanes. Combine larval interruption with sanitation SOPs and inbound quarantine for high-risk SKUs.

- Packaging & kitting floors: Prioritize carton storage, paper-dust hot spots, and trim-waste bins. Reinforce with housekeeping cadence and sealed storage of semi-finished goods.

- Urban 3PL hubs: Standardize inspection at dock doors; apply program in consolidation zones where mixed-origin loads accumulate.

- Textile/archive stores: Couple larval interruption with environmental controls; schedule inspections around seasonality and HVAC maintenance.

- Governance & documentation

- Maintain label-aligned site registers, batch COAs, SDS routing sheets, pallet maps, and photo packs for intake QA.

- Log findings from trap counts and visual checks; trigger corrective actions via threshold rules pre-agreed with QA.

Success indicators (what “good” looks like)

- Declining larval detections across sensitive zones over consecutive audit cycles.

- Stable or reduced adult trap counts despite high inbound turnover.

- Fewer SKU holds and rework events tied to packaging/fiber damage.

- Clean third-party or customer audits with no odor/residue flags.

Boundary conditions

- Do not position as a public-health vector or adult knockdown solution.

- Program value depends on housekeeping and exclusion; chemical control alone will underperform in dusty, unsealed environments.

- Always follow the registered product label and local regulations; no mix recipes or operational dosages are provided here.

Safety, Compliance & Stewardship

Regulatory posture (principle-level)

- Use scope: For licensed buyers operating under local regulations. Follow the registered product label at all times.

- GHS semantics: Present and communicate hazard statements and precautionary statements on artwork per destination market; align pictograms and signal words with local rules.

- Stewardship framework: Risk = Hazard × Exposure. Reduce exposure via engineering controls (enclosures, ventilation), administrative controls (SOPs, training), and PPE consistent with the label.

Storage & transport

- Storage: Keep in original, tightly closed containers in a cool, dry, well-ventilated area away from food/feed and incompatible materials. Prevent freezing/overheating per label.

- Segregation: Separate from oxidizers/strong acids/food-contact items; maintain spill kits at designated points.

- In-transit documentation: Ensure MSDS/SDS routing sheets, packing lists, and emergency contact details accompany shipments per lane requirements.

Worker protection (label-aligned)

- PPE principle: Adopt site-appropriate protection per label—emphasize eye/skin protection during handling and when opening containers.

- Training & signage: Induct staff on label directions, first-aid statements, and site SOPs; mark treated areas per facility policy.

- Incident readiness: Maintain eyewash/first-aid availability and incident reporting workflows; log and investigate any deviations.

Environmental care

- Non-target stewardship: Apply within labeled site/pest scope; avoid off-target release.

- Waste & empties: Manage rinsates/empties per local regulations; do not discharge into drains/waterways contrary to label.

- Program integration: Combine with sanitation, exclusion, and monitoring to minimize chemical load and selection pressure.

Documentation deliverables

- Available: COA, SDS, TDS, label elements, pallet map, photo pack (on request).

- On request/subject to project: Registration support dossier, test summaries (stability/third-party), language-localized artwork.

Compliance note: This page does not provide operational directions, mix recipes, or dosages. Always follow the registered product label and local regulations.

Evidence & Assurance — Proof You Can Hand to QA

Stability & batch control

- Cold/heat storage verification: Each batch cleared against validated protocols prior to release; retention samples archived for traceability.

- Physico-chemical conformance: Appearance, pH window, suspensibility/viscosity meet release criteria; COA issued per lot.

- Change control: Any raw-material or packaging change gated through QA and documented in the dossier.

Third-party & documentation

- Independent testing (where available): Summary reports can be appended to your vendor file under NDA.

- Regulatory documentation: COA, SDS, TDS, label elements; registration support pack on request.

- Photographic QC: In-process and pre-shipment photo sets (filling, capping, coding, cartoning, palletization) supplied for intake checks.

Regional performance notes (qualitative)

- Humid, warm lanes: Low-odor, non-repellent profile supports hygiene standards near packaging lines; program outcomes rely on sanitation cadence.

- Dust-prone warehouses: Pair with deep cleaning and gap sealing to prevent recolonization in corrugated voids.

- Textile/archive environments: Material-friendly profile and non-staining behavior support sensitive collections under IPM.

FAQ

Move from Spec to Stock

Get a Quote / Request OEM Pack

Tell us your market, target pests/sites, expected annual volume, net contents, label languages, and documentation needs (COA/SDS/TDS/registration support). We’ll return a lane-fit proposal with artwork checkpoints, palletization plan, and delivery window.

Request the Starter Dossier

Receive a curated pack: product overview, label elements checklist, packaging options, pallet map sample, and documentation index—ready for your internal approvals.

Contact POMAIS

Partner with a manufacturer that understands stored-product hygiene and urban logistics constraints. Let’s align specs, lock artwork, and ship with confidence.