Tebuconazole 60 g/L FS | Seed Treatment (FRAC 3)

You are sourcing a flowable seed treatment (FS) with tebuconazole 60 g/L—a systemic DMI fungicide (FRAC 3) engineered for professional seed coating lines. In registered crops, you deploy Tebuconazole 60 g/L FS to protect against seed- and soil-borne diseases that undermine stand establishment (e.g., smuts/bunts and early seedling rots), delivering protective and early curative activity at the seed/seedling interface. The FS platform provides controlled viscosity, low settling, good adhesion/film formation, and uniform seed coverage, supporting consistent throughput on rotary or drum treaters. Your commercial outcomes are clean starts, more uniform emergence, and fewer early re-treatments, with optional APE-free and color-standard configurations for market or stewardship requirements. This product is fungicidal only (not insecticidal or herbicidal) and is intended exclusively for treated seed applications; all crops, pathogens, loadings, and label statements are market-specific. Use only as per the approved local label, and mark treated seed clearly—not for food or feed.

- Designed for Professional Buyers & Bulk Orders

- This product is available for business purchase and large-scale distribution.

- We support custom packaging, labeling, and formulation to meet your market needs.

- Let’s build your brand together.

About Tebuconazole 60 g/L FS | Seed Treatment (FRAC 3)

About Tebuconazole 60 g/L FS | Seed Treatment (FRAC 3)

| Item | Specification |

|---|---|

| Product | Tebuconazole 60 g/L FS |

| Use Class | Seed treatment fungicide (professional use) |

| Active & Content | Tebuconazole 60 g/L |

| Mode/FRAC | DMI (FRAC 3) |

| Formulation | FS — flowable concentrate for seed treatment |

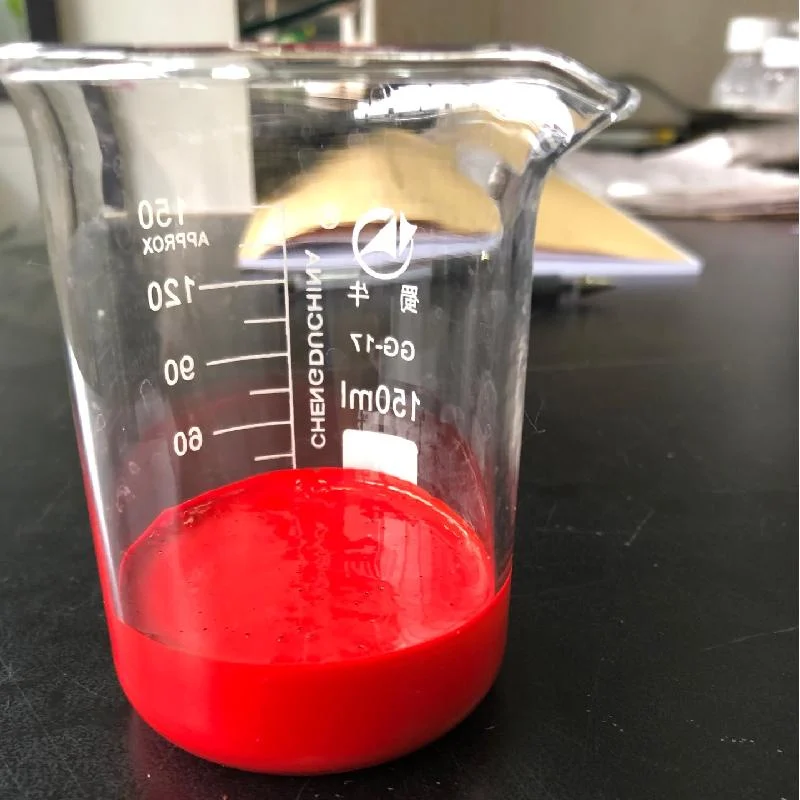

| Appearance | Flowable suspension; typically colored for treated-seed ID |

| Packaging | 1 L / 5 L / 20 L / 200 L (market-dependent) |

| Documents | COA / SDS / TDS supplied per lot |

| Stewardship | Treated seed must be clearly marked; NOT FOR FOOD OR FEED |

| Compliance | Crops, pathogens, loadings, and mixing permissions are label-dependent |

Mode of Action (FRAC 3) — What You’re Buying in Tebuconazole 60 g/L FS

Tebuconazole is a triazole DMI fungicide (FRAC 3) that inhibits C14-demethylation in the fungal sterol pathway (CYP51), depleting ergosterol required for functional cell membranes. In a seed treatment context, this gives you protective + early curative activity directly at the seed/seedling interface: the active is taken up systemically during imbibition and early germination, moving into emerging tissues (coleoptile/hypocotyl) to suppress infections initiated on or within the seed coat and young seedlings. You use it to reduce losses from seed- and soil-borne fungi that drive stand gaps and uneven emergence—subject to your local label.

What this means operationally: with uniform coverage and film integrity from the FS formulation, tebuconazole is positioned to intercept pathogens in the earliest growth window when low biomass magnifies disease impact. The mode of action is single-site, so you should structure rotations or co-formulations with non-FRAC 3 partners where labels allow, and avoid repeated reliance on one MoA across seasons. Note that oomycetes (e.g., Pythium/Phytophthora) are not FRAC 3 targets; broaden protection by selecting compatible partners (as permitted on label) when those pressures are material. Because response depends on pathogen complex, seed quality, temperature, and coating quality, you validate at pilot scale on your line before expanding. Final crops, pathogens, loading limits, coloring requirements, and stewardship statements are label-dependent; mark treated seed clearly and enforce not for food or feed handling.

Disease Spectrum by Segment (label-dependent)

Cereals (wheat, barley, oats, triticale)

You position Tebuconazole 60 g/L FS primarily against seed-borne smuts and bunts in small grains—typical targets include loose/covered smuts and bunt complexes that erode stand and grain quality. In addition, you can expect support on early seedling blights driven by seed-borne Fusarium spp. and certain seed-borne leaf spot pathogens where listed. The value is strongest when you need a clean start, uniform emergence, and reduced early disease carryover into tillering. Final crop and pathogen claims, including any head-stage smut references, must follow your approved label.

Maize / Corn

Where registered, you use tebuconazole FS to reduce seed rot and early seedling blight risk associated with seed-borne Fusarium and related complexes that impair emergence vigor. Because pressure often involves mixed pathogen loads, confirm the exact organisms and claim language on your local label. If oomycetes (e.g., Pythium) are material in your region, select a compatible non-FRAC 3 partner only as permitted by the label.

Soybean & Pulses

On labels that include legumes, tebuconazole FS is positioned for seed mold/seed-borne complex—for example Phomopsis/Diaporthe, Colletotrichum (anthracnose), and Fusarium spp. The commercial outcome you are pursuing is tighter emergence curves and reduced early culls in transplant or field establishment. Verify cultivar sensitivities and the exact species/claims on the approved document before scale-up.

Oilseeds & Brassicas

Where permitted, you deploy tebuconazole FS to lower the seed-borne Alternaria/leaf spot burden and early seedling losses tied to infected lots or sub-optimal storage history. Results depend on seed health, coating quality, and environmental conditions during germination; confirm claim wording and crop inclusion on your label.

Guardrails for all segments

- This is a fungicide (FRAC 3); it does not target oomycetes.

- Spectrum, crops, and statements are market-specific; use only as per the approved local label.

- Mark treated seed clearly and enforce not for food or feed handling.

Formulation Science — FS You Can Run at Scale

Rheology & Physical Stability

Tebuconazole 60 g/L FS is built as an aqueous, flowable suspension tuned for seed treaters. You get a shear-thinning profile that pumps cleanly, meters accurately, and redistributes with modest agitation after idle holds. A controlled yield stress limits sediment compaction in day tanks, while thixotropy lets the slurry wet, spread, and drain without stringing. The dispersion is engineered for low sieve residue and minimal nozzle wear, so you maintain dosing accuracy across long shifts. Short-term tank stability is designed to tolerate recirculation and intermittent stops common to batch or continuous lines. Freeze–thaw and elevated-temperature robustness are validated at spec (no values disclosed here); always store sealed and mix before use per the approved label.

Adhesion, Film & Color Consistency

You need actives to stay on the seed. The FS binder system forms a tack-free, abrasion-resistant film that limits rub-off in handling and transport, supporting low dust figures on Heubach testing. Wetting/dispersing packages are selected for uniform coverage and controlled gloss so you can visually verify treatment quality without bleed or mottling. Pigmentation follows market standards for treated-seed identification; opacity and tint strength are tuned for even appearance across seed lots. Where policy requires, you can specify APE-free surfactant systems and color variants aligned to stewardship codes. Final colorants, hazard phrases, and seed-marking language are label- and country-specific.

Process Compatibility on Industrial Treaters

The formulation is compatible with rotary drums, batch pans, and continuous treaters when used as directed. Low foam supports accurate gravimetric or volumetric dosing; anti-foam performance is balanced to protect sensors and flowmeters. Viscosity and density windows (defined in the TDS/COA) are set for predictable pump curves and line priming. The slurry rinses down with water; follow your site’s CIP and effluent SOPs to avoid cross-contamination. For any new partner (color, polymer, micronutrient, or additional fungicide/insecticide permitted by your label), run a jar test and a pilot-line validation to confirm emulsion/suspension integrity and dry-down. Do not combine with non-label components.

Stewardship Built-In

Formulation choices support treated-seed stewardship: visible coloration, low dusting, and robust film help downstream partners handle, bag, and plant safely. You must mark treated seed clearly and enforce not for food or feed handling. All operating parameters—coating load, drying, compatibility, and clean-out—are governed by your approved local label and plant SOPs.

Program Fit & Stewardship

You position Tebuconazole 60 g/L FS at the seed-conditioning or on-planting treatment window to secure a clean start against label-listed seed- and soil-borne fungi. It fits cereal, pulse, and oilseed programs where uniform emergence and early stand protection drive ROI. Because this is a single-site FRAC 3 (DMI) fungicide, you should design rotations across seasons and, where permitted, pair with non-FRAC 3 partners (e.g., for oomycete pressure) to broaden coverage and slow resistance. Operationally, prioritize seed quality (germ/vigour), correct moisture, and coater calibration to achieve uniform film and dose; verify results with retention samples and routine appearance checks.

Stewardship is non-negotiable: clearly color and label treated seed, enforce NOT FOR FOOD OR FEED, manage dust at the treater and during bagging/planting, and follow site SOPs for clean-out and rinsates. Align storage, transport, and disposal with SDS and local rules. Final crops, pathogens, loading limits, mixing permissions, and any planter/field restrictions are label-dependent; use only as per the approved local label.

QC & Stability

Lot release controls. Each batch of Tebuconazole 60 g/L FS is released against a registered spec. You receive a COA covering active assay (HPLC), appearance/colour, density and pH ranges, viscosity window (shear profile), suspensibility/redisperse time, wet-sieve residue, and foam tendency. Visual and tint checks confirm colour consistency for treated-seed identification. No numerical limits are published here; final ranges follow the approved spec and local registration.

Stability program. Accelerated and real-time studies support shelf-life claims and packaging compatibility. Typical checkpoints include appearance, viscosity drift, particle-size integrity, suspensibility after storage, and colour stability. Freeze–thaw and elevated-temperature challenges are part of the dossier to verify recovery and no hard-settle. Store sealed, cool, and dry; roll or agitate before use after extended storage per label/TDS.

Line validation & treated-seed QA. Before scale-up, run a pilot treater validation to confirm dose accuracy, coverage uniformity, dry-down time, and film integrity on your seed lots. Post-treatment, verify Heubach dust, abrasion resistance, seed flowability, and visual uniformity; retain treated-seed retains for audit and product-performance reviews. Maintain coater calibration and document clean-out to prevent cross-contamination.

Traceability & retention. Every lot carries full traceability from inputs to finished packs; retention samples are archived per lot for the shelf-life period. On receipt, your QA should inspect tamper evidence, pack integrity, label correctness, lot codes, and COA conformance before release to operations. Disposal of rinsates and empties must follow SDS and local regulations.

OEM & Compliance

Private label & artwork. You get end-to-end OEM support for Tebuconazole 60 g/L FS: multilingual labels (EN/ES/FR/AR/RU/PT, etc.), barcode/serialization fields, and optional QR links to an e-leaflet. We align color, typography, and iconography to your brand book while preserving all mandatory hazard statements, precautionary phrases, and treated-seed stewardship language.

Packaging configuration. Choose HDPE bottles or drums with induction seal and tamper evidence; secondary cartons and pallet schemes are optimized for your route-to-market. Color standards for treated-seed ID can be specified to your market’s stewardship codes. Final pack sizes, pictograms, and transport marks are set against the approved spec and local rules.

Documentation bundle. Each lot ships with COA / SDS / TDS. On request, we provide label drafts, carton markings, packaging specs, and master data (SKU codes, dimensions, net/gross weights) to accelerate ERP onboarding and regulatory review.

Regulatory alignment. Claims for crops, pathogens, loadings, mixing permissions, and any planter/field restrictions are label-dependent. You must mark treated seed clearly and enforce NOT FOR FOOD OR FEED across storage, transport, and sales channels. Follow local rules on dust management, bag statements, buffer requirements, and disposal of rinsates/empties. Only trained personnel should handle and apply; keep usage within the approved local label.

FAQ

Q1. What outcomes should you expect from Tebuconazole 60 g/L FS?

A fungicidal seed treatment (FRAC 3) delivering protective and early curative activity against label-listed seed- and soil-borne fungi, supporting clean starts and uniform emergence. Outcomes, crops, and pathogens are label-dependent.

Q2. Does it cover oomycetes (e.g., Pythium/Phytophthora)?

No. FRAC 3 (DMI) does not target oomycetes. Where those pressures matter, select a non-FRAC 3 partner only if your approved local label permits.

Q3. Can you tank mix or co-formulate with other seed-applied inputs?

Only as allowed by the label and your SOPs. Run a jar test and a pilot treater validation for any new partner (polymer, colorant, micronutrient, other fungicide/insecticide).

Q4. What stewardship statements are mandatory?

Clearly mark treated seed, enforce NOT FOR FOOD OR FEED, manage dust at treating, bagging, and planting, and follow local rules on disposal and transport. Use trained personnel only.

Q5. What documentation accompanies each lot?

You receive COA / SDS / TDS. On request: label drafts, carton markings, packaging specs, and master data to speed ERP and regulatory onboarding.

Q6. Which packs are available?

Typical packs: 1 L / 5 L / 20 L / 200 L (market-dependent) in HDPE bottles/drums with induction seals and tamper evidence. Final sizes and marks follow local registration.

Q7. Is an APE-free option available?

Yes, where specified. We can configure APE-free surfactant systems and color standards aligned to stewardship codes, subject to label and market rules.

Request the specification pack for Tebuconazole 60 g/L FS. You will receive COA/SDS/TDS templates, stability summary, label/carton mockups, and a packaging proposal.

To accelerate quoting, share: target crops & pathogens (by market), preferred pack sizes, label languages, annual forecast, and required stewardship statements. We will confirm MOQ, lead time, palletization, and artwork timelines. All claims and use conditions will be finalized against your approved local label.

| Item | Specification |

|---|---|

| Product | Tebuconazole 60 g/L FS |

| Use Class | Seed treatment fungicide (professional use) |

| Active & Content | Tebuconazole 60 g/L |

| Mode/FRAC | DMI (FRAC 3) |

| Formulation | FS — flowable concentrate for seed treatment |

| Appearance | Flowable suspension; typically colored for treated-seed ID |

| Packaging | 1 L / 5 L / 20 L / 200 L (market-dependent) |

| Documents | COA / SDS / TDS supplied per lot |

| Stewardship | Treated seed must be clearly marked; NOT FOR FOOD OR FEED |

| Compliance | Crops, pathogens, loadings, and mixing permissions are label-dependent |

Mode of Action (FRAC 3) — What You’re Buying in Tebuconazole 60 g/L FS

Tebuconazole is a triazole DMI fungicide (FRAC 3) that inhibits C14-demethylation in the fungal sterol pathway (CYP51), depleting ergosterol required for functional cell membranes. In a seed treatment context, this gives you protective + early curative activity directly at the seed/seedling interface: the active is taken up systemically during imbibition and early germination, moving into emerging tissues (coleoptile/hypocotyl) to suppress infections initiated on or within the seed coat and young seedlings. You use it to reduce losses from seed- and soil-borne fungi that drive stand gaps and uneven emergence—subject to your local label.

What this means operationally: with uniform coverage and film integrity from the FS formulation, tebuconazole is positioned to intercept pathogens in the earliest growth window when low biomass magnifies disease impact. The mode of action is single-site, so you should structure rotations or co-formulations with non-FRAC 3 partners where labels allow, and avoid repeated reliance on one MoA across seasons. Note that oomycetes (e.g., Pythium/Phytophthora) are not FRAC 3 targets; broaden protection by selecting compatible partners (as permitted on label) when those pressures are material. Because response depends on pathogen complex, seed quality, temperature, and coating quality, you validate at pilot scale on your line before expanding. Final crops, pathogens, loading limits, coloring requirements, and stewardship statements are label-dependent; mark treated seed clearly and enforce not for food or feed handling.

Disease Spectrum by Segment (label-dependent)

Cereals (wheat, barley, oats, triticale)

You position Tebuconazole 60 g/L FS primarily against seed-borne smuts and bunts in small grains—typical targets include loose/covered smuts and bunt complexes that erode stand and grain quality. In addition, you can expect support on early seedling blights driven by seed-borne Fusarium spp. and certain seed-borne leaf spot pathogens where listed. The value is strongest when you need a clean start, uniform emergence, and reduced early disease carryover into tillering. Final crop and pathogen claims, including any head-stage smut references, must follow your approved label.

Maize / Corn

Where registered, you use tebuconazole FS to reduce seed rot and early seedling blight risk associated with seed-borne Fusarium and related complexes that impair emergence vigor. Because pressure often involves mixed pathogen loads, confirm the exact organisms and claim language on your local label. If oomycetes (e.g., Pythium) are material in your region, select a compatible non-FRAC 3 partner only as permitted by the label.

Soybean & Pulses

On labels that include legumes, tebuconazole FS is positioned for seed mold/seed-borne complex—for example Phomopsis/Diaporthe, Colletotrichum (anthracnose), and Fusarium spp. The commercial outcome you are pursuing is tighter emergence curves and reduced early culls in transplant or field establishment. Verify cultivar sensitivities and the exact species/claims on the approved document before scale-up.

Oilseeds & Brassicas

Where permitted, you deploy tebuconazole FS to lower the seed-borne Alternaria/leaf spot burden and early seedling losses tied to infected lots or sub-optimal storage history. Results depend on seed health, coating quality, and environmental conditions during germination; confirm claim wording and crop inclusion on your label.

Guardrails for all segments

- This is a fungicide (FRAC 3); it does not target oomycetes.

- Spectrum, crops, and statements are market-specific; use only as per the approved local label.

- Mark treated seed clearly and enforce not for food or feed handling.

Formulation Science — FS You Can Run at Scale

Rheology & Physical Stability

Tebuconazole 60 g/L FS is built as an aqueous, flowable suspension tuned for seed treaters. You get a shear-thinning profile that pumps cleanly, meters accurately, and redistributes with modest agitation after idle holds. A controlled yield stress limits sediment compaction in day tanks, while thixotropy lets the slurry wet, spread, and drain without stringing. The dispersion is engineered for low sieve residue and minimal nozzle wear, so you maintain dosing accuracy across long shifts. Short-term tank stability is designed to tolerate recirculation and intermittent stops common to batch or continuous lines. Freeze–thaw and elevated-temperature robustness are validated at spec (no values disclosed here); always store sealed and mix before use per the approved label.

Adhesion, Film & Color Consistency

You need actives to stay on the seed. The FS binder system forms a tack-free, abrasion-resistant film that limits rub-off in handling and transport, supporting low dust figures on Heubach testing. Wetting/dispersing packages are selected for uniform coverage and controlled gloss so you can visually verify treatment quality without bleed or mottling. Pigmentation follows market standards for treated-seed identification; opacity and tint strength are tuned for even appearance across seed lots. Where policy requires, you can specify APE-free surfactant systems and color variants aligned to stewardship codes. Final colorants, hazard phrases, and seed-marking language are label- and country-specific.

Process Compatibility on Industrial Treaters

The formulation is compatible with rotary drums, batch pans, and continuous treaters when used as directed. Low foam supports accurate gravimetric or volumetric dosing; anti-foam performance is balanced to protect sensors and flowmeters. Viscosity and density windows (defined in the TDS/COA) are set for predictable pump curves and line priming. The slurry rinses down with water; follow your site’s CIP and effluent SOPs to avoid cross-contamination. For any new partner (color, polymer, micronutrient, or additional fungicide/insecticide permitted by your label), run a jar test and a pilot-line validation to confirm emulsion/suspension integrity and dry-down. Do not combine with non-label components.

Stewardship Built-In

Formulation choices support treated-seed stewardship: visible coloration, low dusting, and robust film help downstream partners handle, bag, and plant safely. You must mark treated seed clearly and enforce not for food or feed handling. All operating parameters—coating load, drying, compatibility, and clean-out—are governed by your approved local label and plant SOPs.

Program Fit & Stewardship

You position Tebuconazole 60 g/L FS at the seed-conditioning or on-planting treatment window to secure a clean start against label-listed seed- and soil-borne fungi. It fits cereal, pulse, and oilseed programs where uniform emergence and early stand protection drive ROI. Because this is a single-site FRAC 3 (DMI) fungicide, you should design rotations across seasons and, where permitted, pair with non-FRAC 3 partners (e.g., for oomycete pressure) to broaden coverage and slow resistance. Operationally, prioritize seed quality (germ/vigour), correct moisture, and coater calibration to achieve uniform film and dose; verify results with retention samples and routine appearance checks.

Stewardship is non-negotiable: clearly color and label treated seed, enforce NOT FOR FOOD OR FEED, manage dust at the treater and during bagging/planting, and follow site SOPs for clean-out and rinsates. Align storage, transport, and disposal with SDS and local rules. Final crops, pathogens, loading limits, mixing permissions, and any planter/field restrictions are label-dependent; use only as per the approved local label.

QC & Stability

Lot release controls. Each batch of Tebuconazole 60 g/L FS is released against a registered spec. You receive a COA covering active assay (HPLC), appearance/colour, density and pH ranges, viscosity window (shear profile), suspensibility/redisperse time, wet-sieve residue, and foam tendency. Visual and tint checks confirm colour consistency for treated-seed identification. No numerical limits are published here; final ranges follow the approved spec and local registration.

Stability program. Accelerated and real-time studies support shelf-life claims and packaging compatibility. Typical checkpoints include appearance, viscosity drift, particle-size integrity, suspensibility after storage, and colour stability. Freeze–thaw and elevated-temperature challenges are part of the dossier to verify recovery and no hard-settle. Store sealed, cool, and dry; roll or agitate before use after extended storage per label/TDS.

Line validation & treated-seed QA. Before scale-up, run a pilot treater validation to confirm dose accuracy, coverage uniformity, dry-down time, and film integrity on your seed lots. Post-treatment, verify Heubach dust, abrasion resistance, seed flowability, and visual uniformity; retain treated-seed retains for audit and product-performance reviews. Maintain coater calibration and document clean-out to prevent cross-contamination.

Traceability & retention. Every lot carries full traceability from inputs to finished packs; retention samples are archived per lot for the shelf-life period. On receipt, your QA should inspect tamper evidence, pack integrity, label correctness, lot codes, and COA conformance before release to operations. Disposal of rinsates and empties must follow SDS and local regulations.

OEM & Compliance

Private label & artwork. You get end-to-end OEM support for Tebuconazole 60 g/L FS: multilingual labels (EN/ES/FR/AR/RU/PT, etc.), barcode/serialization fields, and optional QR links to an e-leaflet. We align color, typography, and iconography to your brand book while preserving all mandatory hazard statements, precautionary phrases, and treated-seed stewardship language.

Packaging configuration. Choose HDPE bottles or drums with induction seal and tamper evidence; secondary cartons and pallet schemes are optimized for your route-to-market. Color standards for treated-seed ID can be specified to your market’s stewardship codes. Final pack sizes, pictograms, and transport marks are set against the approved spec and local rules.

Documentation bundle. Each lot ships with COA / SDS / TDS. On request, we provide label drafts, carton markings, packaging specs, and master data (SKU codes, dimensions, net/gross weights) to accelerate ERP onboarding and regulatory review.

Regulatory alignment. Claims for crops, pathogens, loadings, mixing permissions, and any planter/field restrictions are label-dependent. You must mark treated seed clearly and enforce NOT FOR FOOD OR FEED across storage, transport, and sales channels. Follow local rules on dust management, bag statements, buffer requirements, and disposal of rinsates/empties. Only trained personnel should handle and apply; keep usage within the approved local label.

FAQ

Q1. What outcomes should you expect from Tebuconazole 60 g/L FS?

A fungicidal seed treatment (FRAC 3) delivering protective and early curative activity against label-listed seed- and soil-borne fungi, supporting clean starts and uniform emergence. Outcomes, crops, and pathogens are label-dependent.

Q2. Does it cover oomycetes (e.g., Pythium/Phytophthora)?

No. FRAC 3 (DMI) does not target oomycetes. Where those pressures matter, select a non-FRAC 3 partner only if your approved local label permits.

Q3. Can you tank mix or co-formulate with other seed-applied inputs?

Only as allowed by the label and your SOPs. Run a jar test and a pilot treater validation for any new partner (polymer, colorant, micronutrient, other fungicide/insecticide).

Q4. What stewardship statements are mandatory?

Clearly mark treated seed, enforce NOT FOR FOOD OR FEED, manage dust at treating, bagging, and planting, and follow local rules on disposal and transport. Use trained personnel only.

Q5. What documentation accompanies each lot?

You receive COA / SDS / TDS. On request: label drafts, carton markings, packaging specs, and master data to speed ERP and regulatory onboarding.

Q6. Which packs are available?

Typical packs: 1 L / 5 L / 20 L / 200 L (market-dependent) in HDPE bottles/drums with induction seals and tamper evidence. Final sizes and marks follow local registration.

Q7. Is an APE-free option available?

Yes, where specified. We can configure APE-free surfactant systems and color standards aligned to stewardship codes, subject to label and market rules.

Request the specification pack for Tebuconazole 60 g/L FS. You will receive COA/SDS/TDS templates, stability summary, label/carton mockups, and a packaging proposal.

To accelerate quoting, share: target crops & pathogens (by market), preferred pack sizes, label languages, annual forecast, and required stewardship statements. We will confirm MOQ, lead time, palletization, and artwork timelines. All claims and use conditions will be finalized against your approved local label.