Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L SE

In-furrow protection at sowing. Dual-MoA confidence for clean roots and stronger starts.

- Dual mode of action: FRAC 11 + 4—broad protection from soil-borne pathogens with added early foliar benefits (per local label).

- SE formulation: Suspo-Emulsion engineered for stable mixing and smooth band placement in the furrow.

- Flexible placement: In-furrow liquid band, surface band, or fertilizer coating—fit it to your seeding system.

- Targets (label-dependent): Rhizoctonia, Pythium; plus stripe rust control and yellow spot suppression in wheat where registered.

- Made for cereals: Ideal for wheat and barley programs; compatible with modern planters and liquid systems.

- Operational wins: One pass at sowing, cleaner root zones, more even emergence, stronger early vigor.

- Ready to ship: SDS/Label/COA available; POMAIS branding or private label; commercial pack sizes 1 L / 5 L / 20 L (others on request).

322 + 124 g/L | SE | FRAC 11 + 4 | In-furrow / Surface band / Fertilizer coating | Cereals focus

Use strictly according to the local registered label. Observe worker safety, environmental directions, REI/PHI, and mixing/placement instructions.

- Designed for Professional Buyers & Bulk Orders

- We support custom packaging, labeling, and formulation to meet your market needs.

- Export wholesale inquiries only.

- Please include destination country, business type (importer/distributor/registrant), and expected volume.

- Retail requests will not be processed.

About Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L SE

| Product | Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L (SE, Suspo-Emulsion) |

| Modes of Action (FRAC) | Group 4 (phenylamide) + Group 11 (QoI) |

| Placement | In-furrow liquid band · Surface band · Fertilizer coating (use per local label) |

| Targets (label-dependent) | Soil-borne: Rhizoctonia, Pythium; Early foliar (where registered): Stripe rust (control), Yellow spot (suppression) |

| Crops (focus) | Wheat, Barley (others only if listed on your local label) |

| Rate format | Per local label (mL/ha or mL per tonne for fertilizer coating) |

| Carrier volume (guideline) | In-furrow: 20–100 L/ha · Surface band: 30–120 L/ha (follow label) |

| Band geometry & seed safety | Band width up to 10 cm; keep ≥15 mm separation from seed line (per label) |

| Mixing order | Water → WDG/WP → SC/SL → SE (this product) → EC → Adjuvants |

| Water quality | Prefer pH 5–7; jar-test with local water and any fertilizers |

| Documents | SDS / Label / COA (batch-matched lot & expiry) |

| Packs | 1 L / 5 L / 20 L (others on request) |

| Branding | POMAIS or Private Label (multilingual artwork) |

| Safety | Professional use; observe REI/PHI, PPE, buffer zones; do not store mixed spray overnight |

| Storage | Sealed, cool, dry, ventilated; keep away from food/feed; observe expiry |

Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L SE

Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L SE is a ready-to-use suspo-emulsion blend that pairs FRAC 11 (QoI) with FRAC 4 (phenylamide) for sowing-time protection. It’s engineered for in-furrow liquid bands, surface bands, or fertilizer coating, giving you one pass at planting to protect the root zone and young foliage (use strictly per local label).

Why it wins in the field

- Dual-MoA breadth (11 + 4): Targets key soil-borne pathogens—especially Rhizoctonia and Pythium—while delivering on-label early foliar benefits such as stripe rust control and yellow spot suppression in wheat where registered.

- Designed for seedlings: Metalaxyl-M moves systemically from the treated zone, while azoxystrobin provides residual protection—together helping clean roots, more even emergence, and strong early vigor under pressure.

- SE formulation advantage: Suspension stability + emulsion spreading = smooth mixing, reliable band placement, low settling, and predictable coverage in modern liquid systems.

- Flexible placement: Choose in-furrow bands for direct root-zone shielding, surface bands when geometry demands, or fert-coating to integrate with your nutrition plan—without adding an extra field pass.

- Operational confidence: Clear guidance on band width, seed spacing, and water volumes helps prevent seed contact and keeps equipment running clean—reducing start-stop headaches at sowing.

- Program fit: A natural backbone for wheat and barley disease programs; tank-mix friendly when allowed (jar test first), and easy to rotate with non-11/non-4 fungicides for resistance stewardship.

Compliance note: Always follow your local registered label for crops, targets, rates, intervals, REI/PHI, and placement specifics.

Actives & Formulation (SE)

Composition & MoA (FRAC-coded)

- Azoxystrobin 322 g/L — FRAC 11 (QoI): broad-spectrum protection with xylem-mobile, translaminar behavior (per label), adding residual coverage to young roots and shoots at sowing.

- Metalaxyl-M 124 g/L — FRAC 4 (phenylamide): targeted oomycete activity and true systemic movement from the treated zone to protect seedlings where Rhizoctonia and Pythium pressure is highest.

- Dual-MoA synergy: two distinct sites of action for robust soil-borne disease programs and label-listed early foliar benefits in cereals.

Why SE (Suspo-Emulsion) beats “one-type” formulations

- Suspension + emulsion in one: mineral solids stay suspended while the emulsion phase spreads evenly—ideal for in-furrow liquid bands and surface bands.

- Reliable mixing & placement: fast dispersion, low settling, and quick re-suspension after pauses help maintain a consistent 10 cm (max) band profile when applied per label guidance.

- Fertilizer-coating friendly: SE handles sprayed fertilizer coating workflows with smoother film formation (follow local label and jar-test with your fertilizer source).

- Operational hygiene: reduced dust compared with dry carriers; rinses out with standard triple-rinse practice; aligns with modern liquid delivery kits on planters.

Quality & documentation

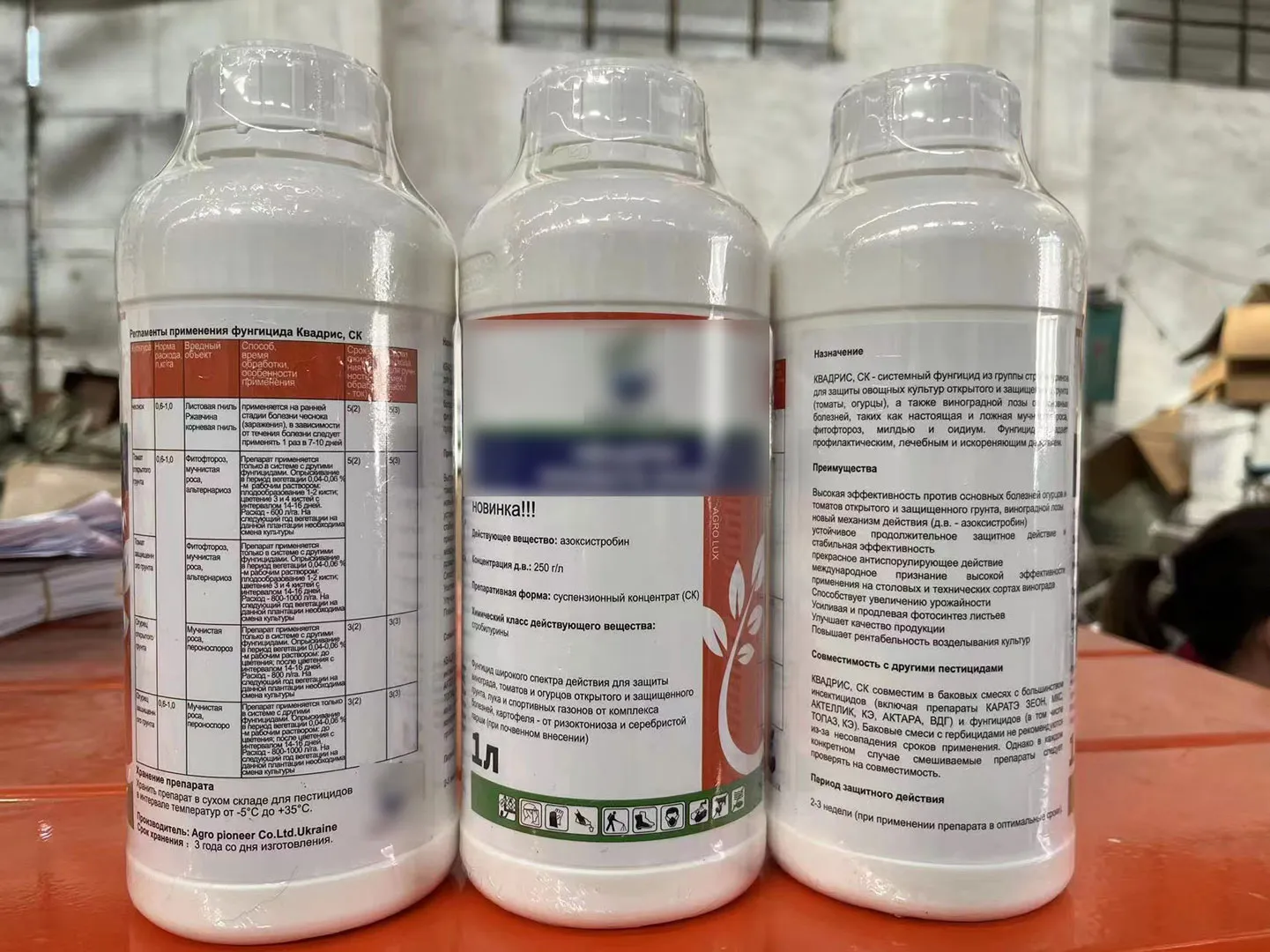

- Identity on pack: “Azoxystrobin 322 g/L + Metalaxyl-M 124 g/L (SE)” clearly shown.

- Traceability: lot & expiry printed on pack; mirrored on COA/SDS for the same batch.

- Unit consistency: content expressed in g/L (w/v); documents and labels align to the same unit system.

- Spec support: COA confirms assay and critical phys-chem checks (appearance, emulsion/suspension behavior, pH window).

Pack options

Standard commercial sizes 1 L / 5 L / 20 L (others on request), supplied under POMAIS or your private label with multilingual artwork.

Placement & Rates (Label-Aligned)

Put protection exactly where seedlings need it—in the furrow, on the surface band, or on the fertilizer—and do it once at sowing. Follow your local registered label for crops, targets, dose and intervals.

Placement overview (at a glance)

| Placement mode | Where it fits | Rate format (per label) | Carrier volume (guideline) | Key setup | Seed safety |

|---|---|---|---|---|---|

| In-furrow liquid band | Standard for cereals; direct root-zone shielding | mL/ha (sometimes mL/100 m row) | 20–100 L/ha total liquid | Band width ≤ 10 cm; stable pump flow; angled tips for uniform band | Keep ≥15 mm gap from seed line |

| Surface band (over row) | When geometry limits in-furrow plumbing | mL/ha | 30–120 L/ha to wet the band | Aim the band centrally over row; avoid drift in wind | Maintain seed offset via soil cover depth |

| Fertilizer coating (pre-plant) | Integrates with granular fertilizer programs | mL or L per tonne fertilizer | Minimal carrier to achieve uniform film | Spray-on tumbler or auger; allow full dry-down before handling | Prevent direct seed contact with wet/undried granules |

Important: Do not exceed label maxima (per hectare or per tonne). If your label specifies band width, seed spacing or flow limits, those values take precedence.

Calibration checklist (quick and practical)

- Metering & flow: Confirm pump output at target speed; lock row-to-row uniformity.

- Nozzles: Choose tips that create a consistent band (≤10 cm); replace worn tips.

- Water quality: Aim pH 5–7; condition hard/alkaline water if needed.

- Mixing order: Water → WDG/WP → SC/SL → SE (this product) → EC → adjuvants; keep agitation on.

- Seed spacing: Verify the ≥15 mm separation between seed and liquid band.

- Coverage proof: Make a short pass, dig and inspect the band—adjust height/angle/pressure before full run.

- Pause & restart: Re-agitate after any stoppage to prevent concentration drift.

- End-of-day hygiene: Triple-rinse tank and lines; don’t store mixed spray overnight.

Operating tips (to keep rates working in the field)

- Target uniform bands rather than heavy spots; uneven bands waste product and risk seed contact.

- Match ground speed and flow rate; re-check after changing seed rate or opener depth.

- Avoid high wind when surface banding; maintain buffer zones where required.

- In fertilizer coating, confirm even film on granules (no clumps), and allow complete drying.

Compliance note

Crops, diseases, dose rates, intervals, REI/PHI, band geometry and seed spacing must follow your local registered label. If your market permits split or surface bands, apply only within label directions.

Target Pathogens & Crops

Built for cereals at sowing, with dual-MoA breadth for soil-borne diseases and label-listed early foliar benefits. Always follow your local registered label for crops, targets, and claims.

Coverage at a glance (examples; label-dependent):

| Crop group | Primary pathogens (program focus) | What you gain in the field |

|---|---|---|

| Wheat | Rhizoctonia, Pythium; plus Stripe Rust (control) and Yellow Spot (suppression) where registered | Cleaner root zone, more even emergence and early vigor; early rust kept in check to protect leaf area at tillering. |

| Barley | Rhizoctonia, Pythium (soil-borne) | Stronger starts under cool/wet soils and stubble; more uniform stands for early canopy closure. |

| Oats / Triticale (where permitted) | Rhizoctonia, Pythium | Sowing-time root protection in conservation tillage systems; helps reduce seedling check. |

| Other cereals (subject to label) | As per local registration | Apply only to crops/diseases listed on your label; consult your POMAIS rep for market-specific guidance. |

Positioning tips

- Target high-risk paddocks: heavy stubble load, cool/wet soils, known Rhizoctonia/Pythium history.

- Time the pass at sowing: in-furrow band or fertilizer coating puts protection where seedlings need it most.

- For wheat markets that allow early foliar claims (stripe rust / yellow spot), keep band geometry and dose on label to secure the early window.

- Scout after emergence: confirm uniform stands and root health; adjust band placement if you see seed contact or uneven bands.

Compliance note

Crops and disease claims vary by country. Only use for label-listed crops and pathogens at the label rate and placement in your market.

Mixing & Compatibility

Built for modern liquid systems — the SE formulation is designed to disperse fast, stay suspended, and place a clean, uniform band. Follow the steps below and always check your local label before mixing.

Water & tank prep

- Start with a clean tank, lines, and strainers; remove alkaline/copper residues.

- Fill tank to ½–⅔ with clean water; target pH 5–7. Condition hard/alkaline water if needed.

- Begin continuous agitation before adding any products.

Order of addition (best practice)

- Water (+ conditioner/buffer if used)

- WDG/WP (disperse fully)

- SC/SL

- SE (POMAIS Metalaxyl-M 124 g/L + Azoxystrobin 322 g/L SE)

- EC

- Adjuvants (oils/surfactants) last

Keep agitation on at all times; do not store mixed spray overnight.

Jar test (5-step, 2 minutes)

- Use local water at field temperature; mimic your tank sequence.

- Add each component in miniature at label ratios; invert/shake 30–60 s.

- Observe layering, gels, flakes, heat, or excessive foam.

- Let stand 10–15 min; re-agitate.

- If stable and uniform → proceed; if not, do not tank-mix.

Fertilizer compatibility (guiding notes)

- Liquid UAN: commonly workable; jar-test for emulsion stability and viscosity rise.

- MAP/DAP granules (spray-on coating): apply light, even film; allow full dry-down before handling/field loading.

- SOA/other salts: watch for crystallization or salting-out; maintain agitation.

- Avoid strong alkalis/oxidizers; consult your supplier before combining with unfamiliar nutrient mixes.

Nozzles, screens & flow

- Aim for a uniform band ≤10 cm (where specified by label) using fan or off-set tips; verify with a short test pass and trench check.

- Use 50–80 mesh strainers; clean if pressure fluctuates.

- Re-agitate after any stoppage to prevent settling/concentration drift.

Do / Don’t quick list

- Do keep seed–band separation ≥15 mm to protect seed safety.

- Do match ground speed to pump output; re-calibrate after any change to opener depth or seed rate.

- Don’t mix in highly alkaline water without conditioning.

- Don’t add adjuvants before the pesticide sequence is complete.

- Don’t spray in high wind when surface-banding; respect buffer zones.

Stewardship & Safety

Use pattern (protect performance & people)

- Rotate modes of action: Alternate away from FRAC 11 + 4 within the season. Avoid back-to-back applications of the same mixture; insert non-11/non-4 fungicides between uses.

- Threshold timing: Treat high-risk paddocks (cool/wet soils, heavy stubble, Rhizoctonia/Pythium history) at sowing with correct band geometry and label dose.

- Good records: Log field, date, rate, placement mode, and MoA to guide future rotations.

Worker safety (per local label & SDS)

- PPE: Chemical-resistant gloves, coveralls, boots, and eye/face protection. Avoid inhaling spray mist or fertilizer dust during coating.

- REI/PHI: Follow re-entry and pre-harvest intervals on your local label. Post signage where required and ventilate enclosed spaces before re-entry.

- Hygiene: Wash hands and exposed skin after handling; launder work clothing separately.

Environmental care

- Aquatic & pollinator protection: Keep out of waterways; establish buffer zones and manage drift. Avoid surface banding in high wind and avoid applications around flowering crops where label restricts.

- Soil & water: Do not apply before heavy rain events that could cause runoff. Prevent spills from entering drains or irrigation channels.

- Containers & rinsate: Triple-rinse; add rinsate to the tank; dispose of containers via approved programs.

Storage & handling

- Store sealed in a cool, dry, ventilated area, away from food/feed and direct heat.

- Keep out of reach of children and unauthorized personnel.

- Do not store mixed spray overnight. Flush tanks/lines after use.

Spill & first aid (summary)

- Spill: Contain with inert absorbent; collect for disposal per regulations; wash the area with minimal water while preventing entry to drains.

- Skin: Wash with soap and water. Eyes: Rinse gently for 15 minutes.

- Inhalation: Move to fresh air and seek medical advice.

- Ingestion: Do not induce vomiting; call a physician or poison center immediately.

- Always consult the SDS and local label for full directions.

Documentation & support

- Batch-matched SDS/Label/COA available on request.

- Technical support can assist with rotation planning, placement checks, and compliance questions.

Packaging, Private Label & Docs

Commercial packs

- Standard sizes: 1 L / 5 L / 20 L (other sizes on request).

- Containers: chemical-resistant HDPE/COEX with CRC caps, tamper-evident bands, and induction liners for leak prevention.

- Outer: export cartons with handling/orientation marks; pallet patterns optimized for container loading.

Private label (POMAIS OEM/ODM)

- Artwork & languages: multilingual GHS labels, barcode/QR, regulatory statements; fast mock-ups based on your brand guide.

- On-pack traceability: lot & expiry printed on primary and secondary packaging; codes mirrored across documents.

- Regional fit: label text adapted to local regulatory terms (per your market’s registered label).

Document pack (per batch)

- SDS & Label (market language available).

- COA confirming assay (g/L) and key phys-chem checks aligned to spec.

- Spec sheet with test items, units, tolerances, and appearance notes.

- Version control: document IDs and revision dates synchronized with the lot.

Logistics & service

- Stable lead times, season-capacity planning, sea/air/courier options; DG paperwork where required.

- Dedicated technical support for label alignment, mixing/placement guidance, and private-label onboarding.