Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS

Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS is a flowable seed-treatment stack that delivers integrated disease-and-insect protection and stable emergence in one bottle: FRAC 12 (fludioxonil) provides a contact shield against Fusarium/Rhizoctonia/Alternaria; FRAC 4 (metalaxyl-M) adds systemic reach on Pythium/Phytophthora damping-off; IRAC 4A (thiamethoxam) supplies early-season, systemic control of sap-feeding pests (e.g., aphids, thrips). The FS formulation is engineered for low dust-off, strong adhesion/color retention, low foaming, and cold/heat storage robustness—treater-friendly and OEM-ready with multilingual labels, batch/QR traceability, and documentation (COA/SDS/TDS/label elements). Typical crop coverage (label-dependent) spans cereals, corn, soybean, cotton, canola/sunflower, and select vegetables, fitting neatly into project-based seed treatment plus field IPM with non-FRAC-4 / non-IRAC-4A rotations.

- Designed for Professional Buyers & Bulk Orders

- This product is available for business purchase and large-scale distribution.

- We support custom packaging, labeling, and formulation to meet your market needs.

- Let’s build your brand together.

About Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS

About Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS

| Product | Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS |

| MoA / Groups | FRAC 12 (contact shield) + FRAC 4 (systemic oomycetes) + IRAC 4A (systemic insect) |

| Focus (label-dependent) | Seed/soil fungi (Fusarium, Rhizoctonia, Alternaria); oomycetes (Pythium, Phytophthora); early aphids/thrips |

| Formulation | FS flowable — low dust-off, strong adhesion/color retention, low foaming |

| Quality Window | pH/viscosity/suspensibility/fineness within release ranges; cold/heat storage: Pass |

| Docs | COA / SDS / TDS / label elements; registration dossier on request |

| OEM & Logistics | Multilingual artwork; batch/QR; anti-counterfeit options; pallet map + photo pack |

Seed Treatment FS | Fludioxonil + Metalaxyl-M + Thiamethoxam

Pain Points (What Buyers Struggle With)

- Uneven emergence under cool/wet starts → seed/soil fungi (Fusarium, Rhizoctonia) and oomycetes (Pythium/Phytophthora) trigger damping-off and replant cost.

- Early insect pressure at stand-up → aphids/thrips reduce vigor and vector viruses; stand uniformity suffers.

- Operational friction on treaters → dust-off, poor adhesion/color retention, foaming, and storage instability slow lines and raise QA rejects.

- Compliance overhead → documentation gaps, label misalignment, and traceability risks block downstream audits.

Gains (Business Outcomes You Can Quantify)

- Higher stand establishment & uniformity → cleaner radicles/hypocotyls, fewer skips, tighter harvest window.

- Reduced early rework → lower replant/ rescue interventions; better input ROI in high-inoculum zones.

- Smoother treating operations → FS engineered for low dust-off / strong adhesion / stable dispersion / low foaming, helping keep throughput and coating quality on spec.

- Audit-ready supply → COA/SDS/TDS/label elements + batch/QR traceability to pass buyer audits and regulatory checks.

Differentiators (Why This FS Stack Wins)

- Three-path protection in one bottle — FRAC 12 contact shield (fludioxonil) + FRAC 4 systemic oomycete reach (metalaxyl-M) + IRAC 4A early insect control (thiamethoxam) for disease–insect dual coverage.

- Engineered for treaters — formulation targets adhesion & color retention with anti-settling rheology; designed to be treater-friendly across long runs.

- Program fit & stewardship-ready — clean hand-off to field IPM with non-FRAC-4 / non-IRAC-4A rotations to manage resistance.

- OEM scalability — multilingual artwork, private-label readiness, photo-documented palletization; change-control governance without exposing proprietary formulation parameters.

Active Ingredients & Modes of Action — FRAC 12 + FRAC 4 + IRAC 4A (Seed Treatment FS)

Fludioxonil (11 g/L) — FRAC 12, Contact Shield for Seed-/Soil-Borne Fungi

Creates a surface protective film on the seed, disrupting fungal osmoregulation and spore germination. Strong fit for Fusarium, Rhizoctonia, Alternaria at the seed/seedling interface, supporting clean radicles and hypocotyls. As a contact phenylpyrrole, it complements systemic partners without adding resistance pressure to oomycetes.

Metalaxyl-M (17 g/L) — FRAC 4, Systemic Oomycete Specialist

Translocates into the germinating seedling to suppress Pythium/Phytophthora damping-off. The value is inside-leaf/inside-tissue reach precisely during vulnerable emergence. Because phenylamides carry known resistance risk in some geographies, use within strict rotations with non-FRAC-4 partners later in the field program.

Thiamethoxam (222 g/L) — IRAC 4A, Systemic Early-Season Insect Protection

A neonicotinoid that moves systemically to protect emerging tissue from sap-feeding pests (e.g., aphids, thrips) and certain early soil pests as permitted by label. Outcome: more uniform stands and reduced early vigor loss caused by feeding or virus transmission pressure.

Why This Trio Works — “Outside + Inside + Insect” Design

- Outside: fludioxonil establishes a contact shield where infections start.

- Inside: metalaxyl-M delivers systemic oomycete control during germination.

- Insect: thiamethoxam buffers early pest pressure, protecting vigor.

Combined, they address the multi-factor causes of poor stands in cool/wet or high-inoculum starts—without operational complexity at the treater.

Stewardship & Boundaries (Principle-Level)

- Keep field-season rotations with non-FRAC-4 fungicides and non-IRAC-4A insecticides to manage resistance.

- Observe pollinator and dust-management rules for treated seed where applicable.

- Do not extrapolate beyond registered crops/targets/sites; this page is non-operational (no rates, mixes, or treater settings).

Target Spectrum & Crop Fit — Seed-/Soil-Borne Diseases, Oomycetes & Early Insects (label-dependent)

Disease Spectrum — Seed & Soil Fungi (FRAC 12) + Oomycetes (FRAC 4)

- Seed-/soil-borne fungi: Fusarium spp., Rhizoctonia solani, Alternaria spp. — addressed by fludioxonil (FRAC 12) as a contact seed-surface shield, supporting clean radicles and hypocotyls during germination.

- Oomycetes (damping-off): Pythium spp. / Phytophthora spp. — targeted by metalaxyl-M (FRAC 4) with systemic translocation into the emerging seedling for early protection.

- Program note: This is a seed-treatment defense focused on pre-emergence to early establishment; field-season foliar issues outside this scope require separate, non-FRAC-4 partners per label.

Early-Season Insect Spectrum — Systemic Protection (IRAC 4A)

- Sap-feeding pests: aphids, thrips (vector-management benefit depends on crop/pathosystem).

- Selected soil/seedling pests: where listed on the registered label, thiamethoxam (IRAC 4A) provides systemic early protection to preserve vigor and stand uniformity.

- Stewardship: Align with regional neonic guidance (dust-off mitigation, pollinator safeguards) and rotate to non-IRAC-4A modes in field programs.

Crop Fit — Typical Registrations

- Cereals (wheat, barley, oats) — seed/soil fungi + Pythium risk under cool/wet starts.

- Corn & soybean — damping-off complexes; early aphids/thrips pressure where relevant.

- Cotton, canola/rapeseed, sunflower — emergence protection under high inoculum or cold soils.

- Vegetables (selected) — label-specific; treaters use for stand establishment in protected or open-field nurseries.

- Boundary: Do not extrapolate beyond the registered crop/site/target list; greenhouse vs. open-field scope is label-defined.

| Crop Group | Primary Risks at Planting | Protection Path | Program Hand-off |

|---|---|---|---|

| Cereals | Fusarium, Rhizoctonia, Pythium | FRAC 12 (contact) + FRAC 4 (systemic) | Rotate to non-4 fungicides in foliar stages |

| Corn / Soybean | Damping-off, early aphids/thrips | FRAC 4 + IRAC 4A | Field IPM with non-4 / non-4A partners |

| Cotton / Canola / Sunflower | Cool soils, high inoculum | FRAC 12 + FRAC 4 | Stewardship rotation per label |

| Selected Vegetables | Nursery stand losses | FRAC 12 + FRAC 4 + IRAC 4A | Label-aligned transitions to field sprays |

Formulation & Quality Window — FS Engineering (Principle-Level, Non-Operational)

Design intent. Flowable seed-treatment (FS) engineered for low dust-off, strong adhesion/color retention, stable dispersion/anti-settling, and low foaming—to keep treater lines smooth and coating quality consistent across long runs.

Process & consistency. Technical actives qualified on identity/purity → controlled dispersion/wet-milling (PSD governed in ranges) → in-process QC at critical control points (appearance, pH, viscosity, suspensibility, fineness/screening) → lot release on dossier sign-off.

Quality window (range-based). Uniform aqueous suspension; pH within validated window for FS stability; pumpable rheology; suspensibility and sieve smoothness meeting internal release limits; foam controlled for treater efficiency.

Stability. Cold/heat storage: Pass under validated protocols; shelf life supported when stored sealed, cool, dry, and ventilated per label.

Documentation. Each lot ships with COA/SDS/TDS/label elements; retention samples archived; raw-material/packaging changes governed by documented change control.

Program Fit & Resistance Management — Seed Block Now, Smart Rotations Later

Role at planting. Foundation seed block that addresses seed/soil fungi (FRAC 12), oomycetes (FRAC 4), and early insects (IRAC 4A) from pre-emergence to early establishment.

Field-season hand-off. Transition to foliar/soil programs using non-FRAC-4 fungicides and non-IRAC-4A insecticides; avoid phenylamide and neonic back-to-back exposure across the season.

IPM alignment. Pair with sanitation, calibrated treaters, dust mitigation at planting, seedbed drainage, and stand scouting; adjust rotations if reduced sensitivity is suspected.

Safety & Compliance — GHS Alignment, Treated-Seed Stewardship, Geography

Label-first principle. Supply to licensed buyers; all crops/sites, targets, intervals, and treater settings are label-governed.

GHS/worker protection. Synchronize hazard/precautionary statements, signal words, pictograms, and emergency contacts across label/SDS in destination languages; train operators on PPE and first-aid statements.

Treated seed stewardship. Implement dust-off control (polymer, talc/graphite and exhaust filtration per local practice), disposal rules for excess slurry, and “Not for food/feed/oil processing” seed labeling where required.

Neonic policy (IRAC 4A). Observe regional rules on pollinator safeguards (planting dust management, flowering crop restrictions) and any geography-specific limits for thiamethoxam.

Packaging & OEM — Treater-Ready Packs, Multilingual Artwork, Traceability

Pack options. Treater-friendly bottles/cans sized for dosing cabinets (e.g., 1–5 L operational packs; 10–20 L plant packs); HDPE/PET with tamper-evident closures; colorant-compatible.

Artwork & languages. Multilingual labels (EN/ES/FR/AR/RU; others on request) with claims/legal alignment, barcodes/serialization, and batch/QR traceability; optional anti-counterfeit (hologram/unique codes).

Route-to-market workflow. Scope & compliance mapping → artwork lock → pre-production proofs → lot release (COA/SDS/TDS) → logistics kit (pallet map, packing list, SDS routing) + shipment photo pack for intake QA.

Evidence & Assurance — Stability, Batch Control & NDA Summaries

Stability summary. Lots are cleared only after cold/heat storage verification and QC fields meet internal windows (appearance, pH, viscosity, suspensibility, fineness/screening).

Batch control. COA per lot, synchronized SDS/TDS, retention samples archived for traceability; deviations and supplier substitutions handled under change control.

Third-party support. Independent test summaries or regulatory excerpts can be shared under NDA; proprietary parameters remain undisclosed.

FAQ

Get a Quote

Share markets, crops/sites, annual volumes, pack sizes, label languages, and documentation needs. We will return an audit-ready proposal with artwork checkpoints, pallet plan, and delivery window.

Request a Compliance & OEM Pack

Receive a curated dossier: label-elements checklist, packaging options, pallet map sample, documentation index, and shipment photo pack.

Other Fludioxonil Formulations

Other Metalaxyl-M Formulations

Other Thiamethoxam Formulations

| Product | Fludioxonil 11 g/L + Metalaxyl-M 17 g/L + Thiamethoxam 222 g/L FS |

| MoA / Groups | FRAC 12 (contact shield) + FRAC 4 (systemic oomycetes) + IRAC 4A (systemic insect) |

| Focus (label-dependent) | Seed/soil fungi (Fusarium, Rhizoctonia, Alternaria); oomycetes (Pythium, Phytophthora); early aphids/thrips |

| Formulation | FS flowable — low dust-off, strong adhesion/color retention, low foaming |

| Quality Window | pH/viscosity/suspensibility/fineness within release ranges; cold/heat storage: Pass |

| Docs | COA / SDS / TDS / label elements; registration dossier on request |

| OEM & Logistics | Multilingual artwork; batch/QR; anti-counterfeit options; pallet map + photo pack |

Seed Treatment FS | Fludioxonil + Metalaxyl-M + Thiamethoxam

Pain Points (What Buyers Struggle With)

- Uneven emergence under cool/wet starts → seed/soil fungi (Fusarium, Rhizoctonia) and oomycetes (Pythium/Phytophthora) trigger damping-off and replant cost.

- Early insect pressure at stand-up → aphids/thrips reduce vigor and vector viruses; stand uniformity suffers.

- Operational friction on treaters → dust-off, poor adhesion/color retention, foaming, and storage instability slow lines and raise QA rejects.

- Compliance overhead → documentation gaps, label misalignment, and traceability risks block downstream audits.

Gains (Business Outcomes You Can Quantify)

- Higher stand establishment & uniformity → cleaner radicles/hypocotyls, fewer skips, tighter harvest window.

- Reduced early rework → lower replant/ rescue interventions; better input ROI in high-inoculum zones.

- Smoother treating operations → FS engineered for low dust-off / strong adhesion / stable dispersion / low foaming, helping keep throughput and coating quality on spec.

- Audit-ready supply → COA/SDS/TDS/label elements + batch/QR traceability to pass buyer audits and regulatory checks.

Differentiators (Why This FS Stack Wins)

- Three-path protection in one bottle — FRAC 12 contact shield (fludioxonil) + FRAC 4 systemic oomycete reach (metalaxyl-M) + IRAC 4A early insect control (thiamethoxam) for disease–insect dual coverage.

- Engineered for treaters — formulation targets adhesion & color retention with anti-settling rheology; designed to be treater-friendly across long runs.

- Program fit & stewardship-ready — clean hand-off to field IPM with non-FRAC-4 / non-IRAC-4A rotations to manage resistance.

- OEM scalability — multilingual artwork, private-label readiness, photo-documented palletization; change-control governance without exposing proprietary formulation parameters.

Active Ingredients & Modes of Action — FRAC 12 + FRAC 4 + IRAC 4A (Seed Treatment FS)

Fludioxonil (11 g/L) — FRAC 12, Contact Shield for Seed-/Soil-Borne Fungi

Creates a surface protective film on the seed, disrupting fungal osmoregulation and spore germination. Strong fit for Fusarium, Rhizoctonia, Alternaria at the seed/seedling interface, supporting clean radicles and hypocotyls. As a contact phenylpyrrole, it complements systemic partners without adding resistance pressure to oomycetes.

Metalaxyl-M (17 g/L) — FRAC 4, Systemic Oomycete Specialist

Translocates into the germinating seedling to suppress Pythium/Phytophthora damping-off. The value is inside-leaf/inside-tissue reach precisely during vulnerable emergence. Because phenylamides carry known resistance risk in some geographies, use within strict rotations with non-FRAC-4 partners later in the field program.

Thiamethoxam (222 g/L) — IRAC 4A, Systemic Early-Season Insect Protection

A neonicotinoid that moves systemically to protect emerging tissue from sap-feeding pests (e.g., aphids, thrips) and certain early soil pests as permitted by label. Outcome: more uniform stands and reduced early vigor loss caused by feeding or virus transmission pressure.

Why This Trio Works — “Outside + Inside + Insect” Design

- Outside: fludioxonil establishes a contact shield where infections start.

- Inside: metalaxyl-M delivers systemic oomycete control during germination.

- Insect: thiamethoxam buffers early pest pressure, protecting vigor.

Combined, they address the multi-factor causes of poor stands in cool/wet or high-inoculum starts—without operational complexity at the treater.

Stewardship & Boundaries (Principle-Level)

- Keep field-season rotations with non-FRAC-4 fungicides and non-IRAC-4A insecticides to manage resistance.

- Observe pollinator and dust-management rules for treated seed where applicable.

- Do not extrapolate beyond registered crops/targets/sites; this page is non-operational (no rates, mixes, or treater settings).

Target Spectrum & Crop Fit — Seed-/Soil-Borne Diseases, Oomycetes & Early Insects (label-dependent)

Disease Spectrum — Seed & Soil Fungi (FRAC 12) + Oomycetes (FRAC 4)

- Seed-/soil-borne fungi: Fusarium spp., Rhizoctonia solani, Alternaria spp. — addressed by fludioxonil (FRAC 12) as a contact seed-surface shield, supporting clean radicles and hypocotyls during germination.

- Oomycetes (damping-off): Pythium spp. / Phytophthora spp. — targeted by metalaxyl-M (FRAC 4) with systemic translocation into the emerging seedling for early protection.

- Program note: This is a seed-treatment defense focused on pre-emergence to early establishment; field-season foliar issues outside this scope require separate, non-FRAC-4 partners per label.

Early-Season Insect Spectrum — Systemic Protection (IRAC 4A)

- Sap-feeding pests: aphids, thrips (vector-management benefit depends on crop/pathosystem).

- Selected soil/seedling pests: where listed on the registered label, thiamethoxam (IRAC 4A) provides systemic early protection to preserve vigor and stand uniformity.

- Stewardship: Align with regional neonic guidance (dust-off mitigation, pollinator safeguards) and rotate to non-IRAC-4A modes in field programs.

Crop Fit — Typical Registrations

- Cereals (wheat, barley, oats) — seed/soil fungi + Pythium risk under cool/wet starts.

- Corn & soybean — damping-off complexes; early aphids/thrips pressure where relevant.

- Cotton, canola/rapeseed, sunflower — emergence protection under high inoculum or cold soils.

- Vegetables (selected) — label-specific; treaters use for stand establishment in protected or open-field nurseries.

- Boundary: Do not extrapolate beyond the registered crop/site/target list; greenhouse vs. open-field scope is label-defined.

| Crop Group | Primary Risks at Planting | Protection Path | Program Hand-off |

|---|---|---|---|

| Cereals | Fusarium, Rhizoctonia, Pythium | FRAC 12 (contact) + FRAC 4 (systemic) | Rotate to non-4 fungicides in foliar stages |

| Corn / Soybean | Damping-off, early aphids/thrips | FRAC 4 + IRAC 4A | Field IPM with non-4 / non-4A partners |

| Cotton / Canola / Sunflower | Cool soils, high inoculum | FRAC 12 + FRAC 4 | Stewardship rotation per label |

| Selected Vegetables | Nursery stand losses | FRAC 12 + FRAC 4 + IRAC 4A | Label-aligned transitions to field sprays |

Formulation & Quality Window — FS Engineering (Principle-Level, Non-Operational)

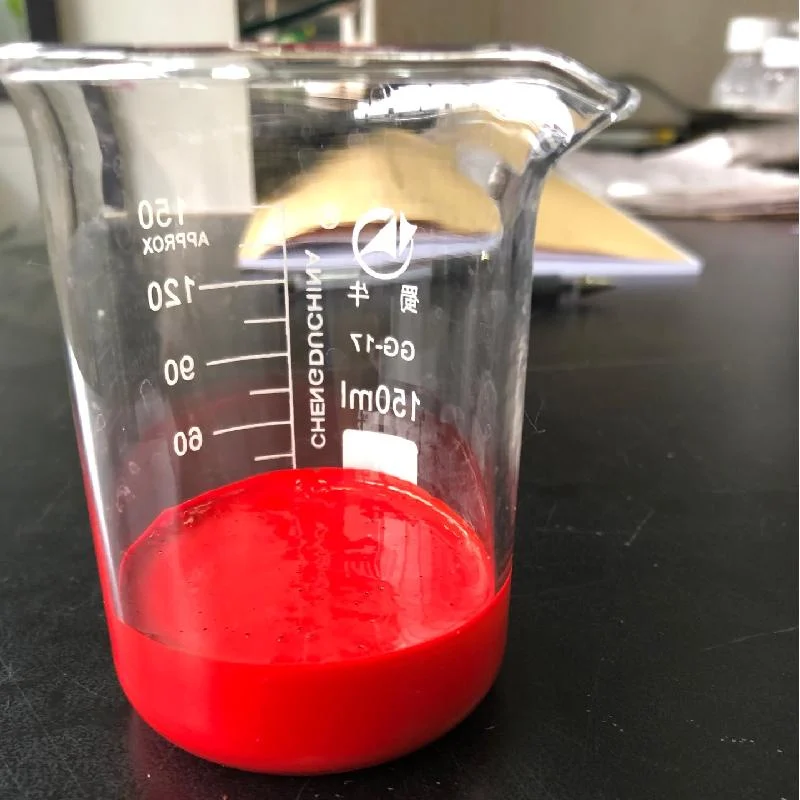

Design intent. Flowable seed-treatment (FS) engineered for low dust-off, strong adhesion/color retention, stable dispersion/anti-settling, and low foaming—to keep treater lines smooth and coating quality consistent across long runs.

Process & consistency. Technical actives qualified on identity/purity → controlled dispersion/wet-milling (PSD governed in ranges) → in-process QC at critical control points (appearance, pH, viscosity, suspensibility, fineness/screening) → lot release on dossier sign-off.

Quality window (range-based). Uniform aqueous suspension; pH within validated window for FS stability; pumpable rheology; suspensibility and sieve smoothness meeting internal release limits; foam controlled for treater efficiency.

Stability. Cold/heat storage: Pass under validated protocols; shelf life supported when stored sealed, cool, dry, and ventilated per label.

Documentation. Each lot ships with COA/SDS/TDS/label elements; retention samples archived; raw-material/packaging changes governed by documented change control.

Program Fit & Resistance Management — Seed Block Now, Smart Rotations Later

Role at planting. Foundation seed block that addresses seed/soil fungi (FRAC 12), oomycetes (FRAC 4), and early insects (IRAC 4A) from pre-emergence to early establishment.

Field-season hand-off. Transition to foliar/soil programs using non-FRAC-4 fungicides and non-IRAC-4A insecticides; avoid phenylamide and neonic back-to-back exposure across the season.

IPM alignment. Pair with sanitation, calibrated treaters, dust mitigation at planting, seedbed drainage, and stand scouting; adjust rotations if reduced sensitivity is suspected.

Safety & Compliance — GHS Alignment, Treated-Seed Stewardship, Geography

Label-first principle. Supply to licensed buyers; all crops/sites, targets, intervals, and treater settings are label-governed.

GHS/worker protection. Synchronize hazard/precautionary statements, signal words, pictograms, and emergency contacts across label/SDS in destination languages; train operators on PPE and first-aid statements.

Treated seed stewardship. Implement dust-off control (polymer, talc/graphite and exhaust filtration per local practice), disposal rules for excess slurry, and “Not for food/feed/oil processing” seed labeling where required.

Neonic policy (IRAC 4A). Observe regional rules on pollinator safeguards (planting dust management, flowering crop restrictions) and any geography-specific limits for thiamethoxam.

Packaging & OEM — Treater-Ready Packs, Multilingual Artwork, Traceability

Pack options. Treater-friendly bottles/cans sized for dosing cabinets (e.g., 1–5 L operational packs; 10–20 L plant packs); HDPE/PET with tamper-evident closures; colorant-compatible.

Artwork & languages. Multilingual labels (EN/ES/FR/AR/RU; others on request) with claims/legal alignment, barcodes/serialization, and batch/QR traceability; optional anti-counterfeit (hologram/unique codes).

Route-to-market workflow. Scope & compliance mapping → artwork lock → pre-production proofs → lot release (COA/SDS/TDS) → logistics kit (pallet map, packing list, SDS routing) + shipment photo pack for intake QA.

Evidence & Assurance — Stability, Batch Control & NDA Summaries

Stability summary. Lots are cleared only after cold/heat storage verification and QC fields meet internal windows (appearance, pH, viscosity, suspensibility, fineness/screening).

Batch control. COA per lot, synchronized SDS/TDS, retention samples archived for traceability; deviations and supplier substitutions handled under change control.

Third-party support. Independent test summaries or regulatory excerpts can be shared under NDA; proprietary parameters remain undisclosed.

FAQ

Get a Quote

Share markets, crops/sites, annual volumes, pack sizes, label languages, and documentation needs. We will return an audit-ready proposal with artwork checkpoints, pallet plan, and delivery window.

Request a Compliance & OEM Pack

Receive a curated dossier: label-elements checklist, packaging options, pallet map sample, documentation index, and shipment photo pack.